Device for leading out sensor cable in ultralow-temperature high-pressure environment and installation method thereof

A high-pressure environment and sensor technology, applied in the field of ultra-low temperature, to achieve the effect of avoiding seal failure leakage, good sealing performance, and ensuring sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

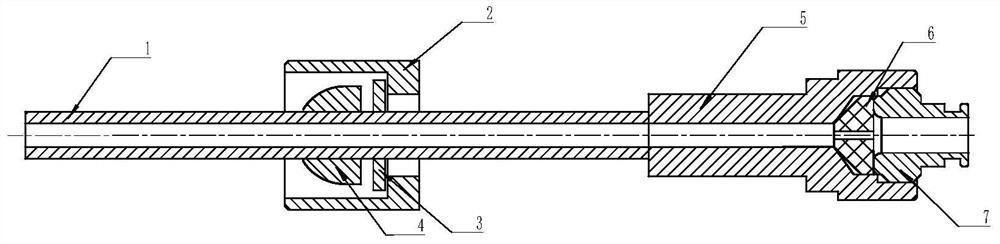

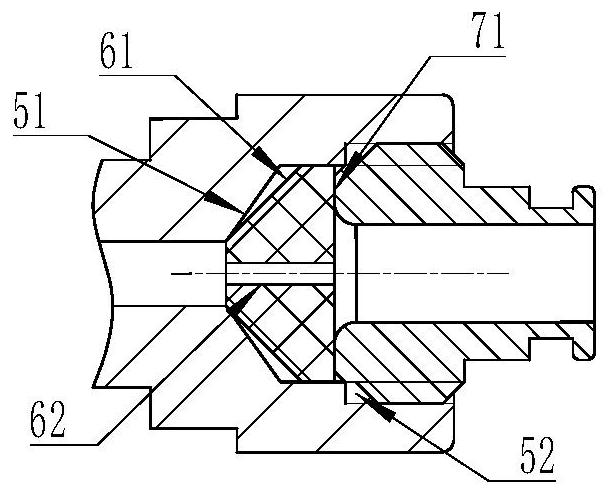

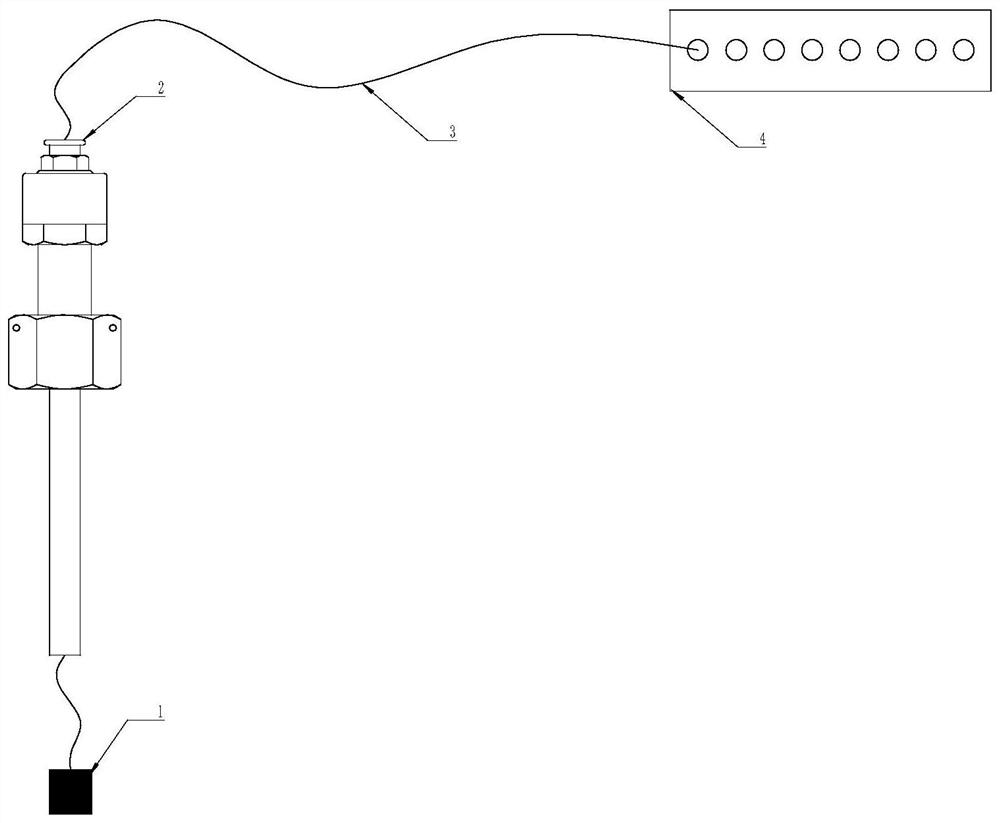

[0030] A device and its installation method for leading out sensor cables in an ultra-low temperature and high pressure environment. The device is sealed at two places. The low temperature end is sealed to prevent liquid nitrogen from leaking from the outer wall of the extension rod. The normal temperature part is sealed by a sealing body and injected with hot melt adhesive. The tetrafluoroethylene ball head is sealed with the through joint, the sealing performance is reliable, and the working pressure can reach more than 2MPa. In order to ensure the sealing of the outlet of the sensor cable, the cable is properly extended through the extension rod, so that the ultra-low temperature will not be transmitted to the outlet of the wire, and the outlet end of the cable can be sealed by using the normal temperature sealing method, which can be effectively reinforced by the lock nut and rubber pad cable, to ensure sealing performance.

[0031] The device for leading out the sensor ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com