Method for cleaning air cooler as well as device for carrying out the method, and air cooler equipped for the same

An air cooler and air technology, applied in the direction of cleaning heat transfer devices, engine cooling, installation, etc., can solve the problems of accelerated cooler component corrosion, increased maintenance and maintenance costs, and unfavorable service life, etc., to achieve reliable removal, small Structural size, the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

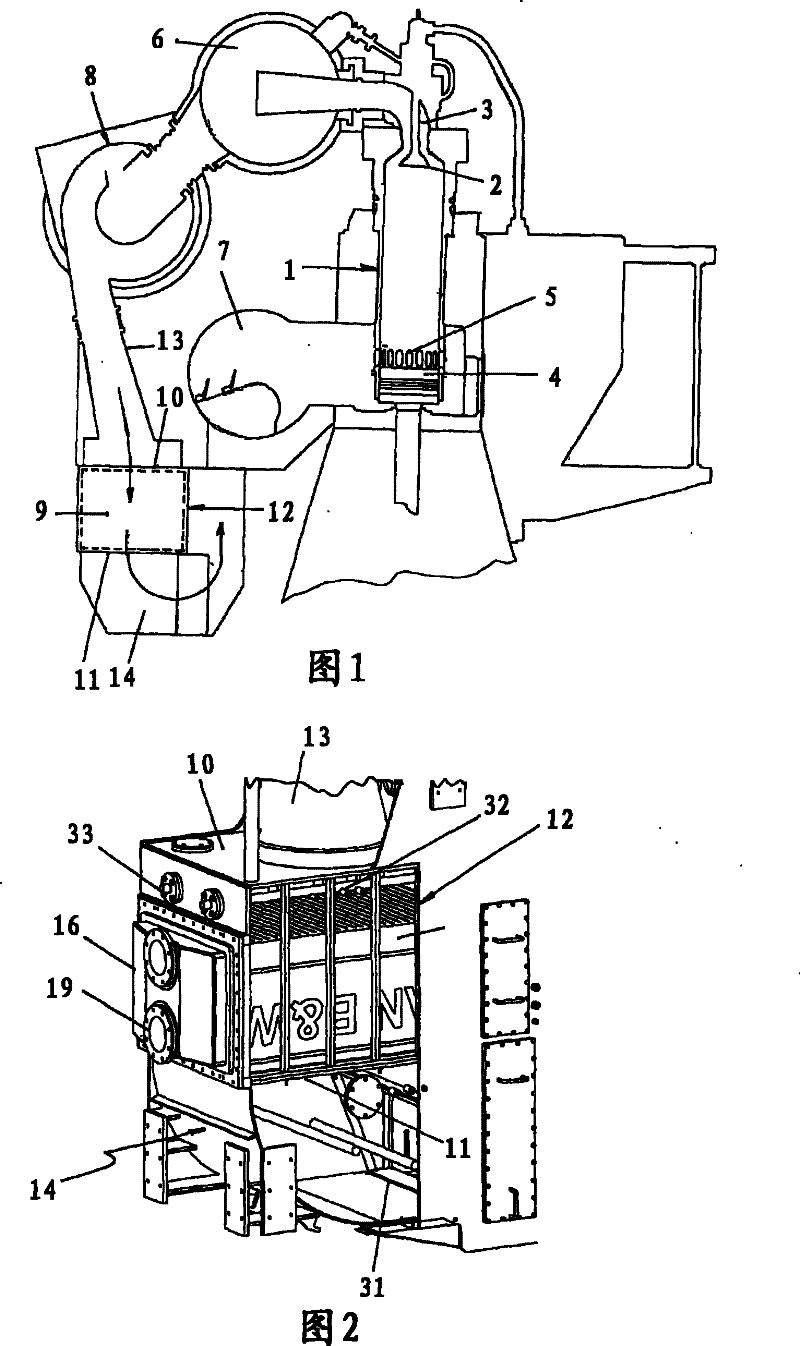

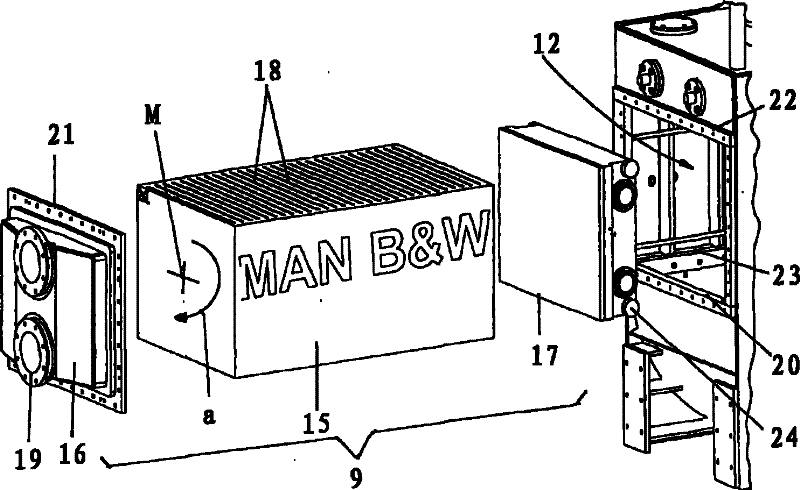

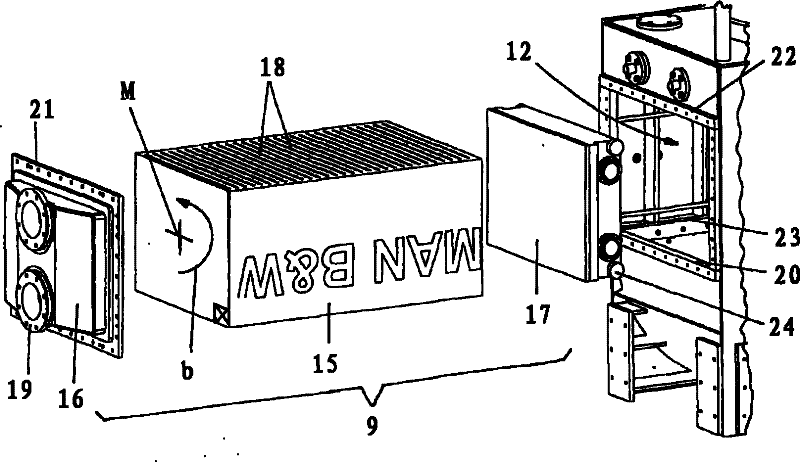

[0026] An important field of application of the invention is large engines, such as large two-stroke diesel engines, preferably provided with an exhaust gas turbocharger. Engines of this type are used extensively in marine propulsion. exist figure 1 An engine of this type is shown in . Although the invention will be described by means of this preferred embodiment, it should not be construed as limiting the invention thereto.

[0027] asfigure 1 Engines of the basic type generally comprise a plurality of cylinders 1 arranged side by side in rows, said cylinders having an upper exhaust gas outlet 3 controllable by an exhaust valve 2 and a lower one controlled by pistons 4 which move up and down. The air inlet slit 5 is used to supply the necessary air to the working chamber through the air inlet slit. The exhaust gas outlets 3 of the cylinders 1 lead into an exhaust gas manifold 6 . The air inlet slit communicates with a distribution pipe 7 . In naturally aspirated engines,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com