Rivet installation tool having automatic riveting core guiding out mechanism

A technology for rivets and utensils, which is applied in the field of rivet installation utensils with an automatic rivet core export mechanism, and can solve problems such as impact and poor health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

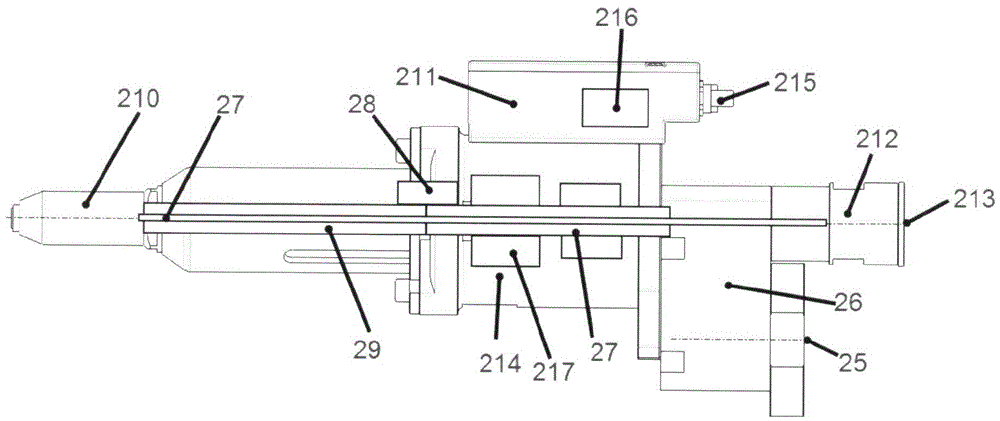

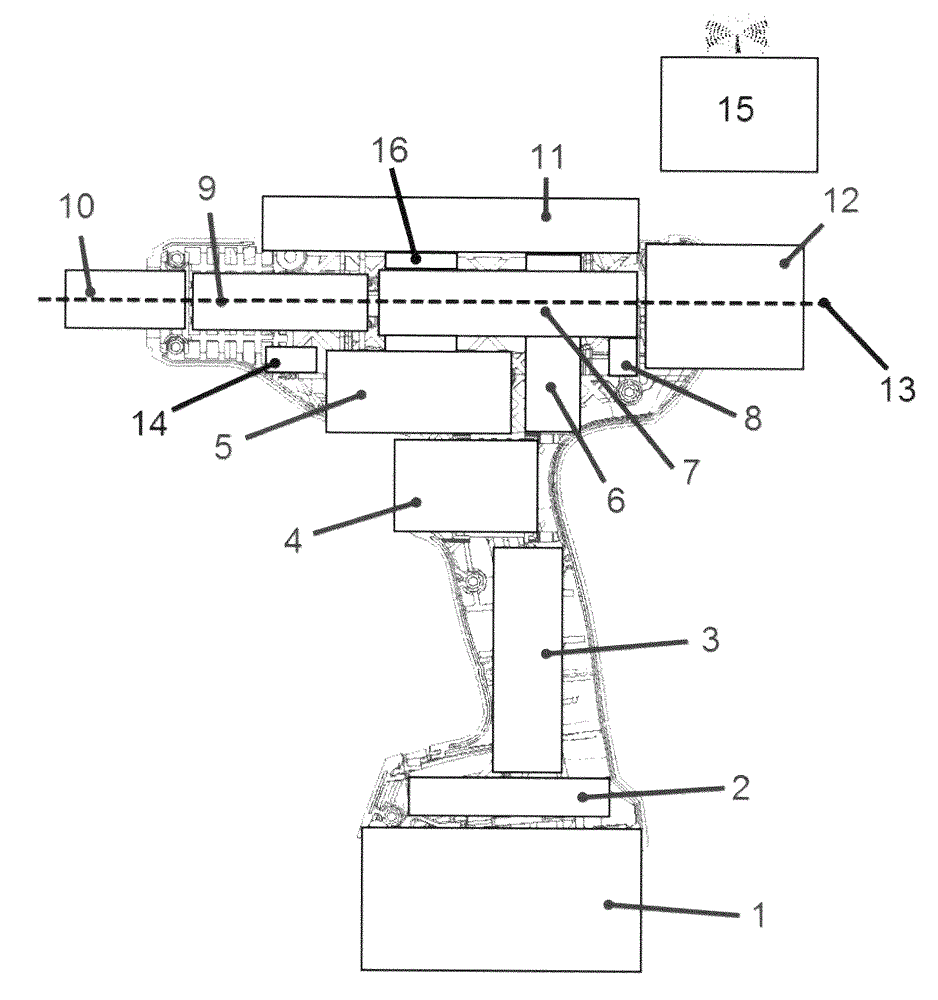

[0026] exist figure 1 The riveting tool shown in is used for installing blind rivets or blind nuts consisting of a rivet sleeve and a separable rivet mandrel. This is a battery-operated appliance for manual operation. A tool head 10 with a nozzle piece for holding the rivet mandrel is provided. Along the same axis 13, the tool head 10 and / or the force sensor with the rivet lead-through 9 and / or the trapezoidal screw or the ball screw 7 with the rivet lead-through 7 and / or preferably the rivet container are arranged next to each other 12. The rivet mandrel clamped by the nozzle part during operation can be guided through the above-mentioned components 10, 9, 7 by means of the rivet mandrel outlet channel (not shown) as far as the said rivet mandrel after its separation. Rivet mandrel container 12.

[0027] The trapezoidal screw or ball screw 7 is driven by means of the electric motor 5 , preferably in conjunction with the transmission 6 , possibly with offset. A stroke sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com