Transmission shell, transmission unit, driving unit, and ground transportation tool

A technology for transmission housings and means of transportation, which is applied in the field of transmissions of devices, and can solve problems such as loss of lubricating oil, leakage of lubricating oil, leakage of lubricating oil, etc., and achieve the effect of low cost and small structural space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

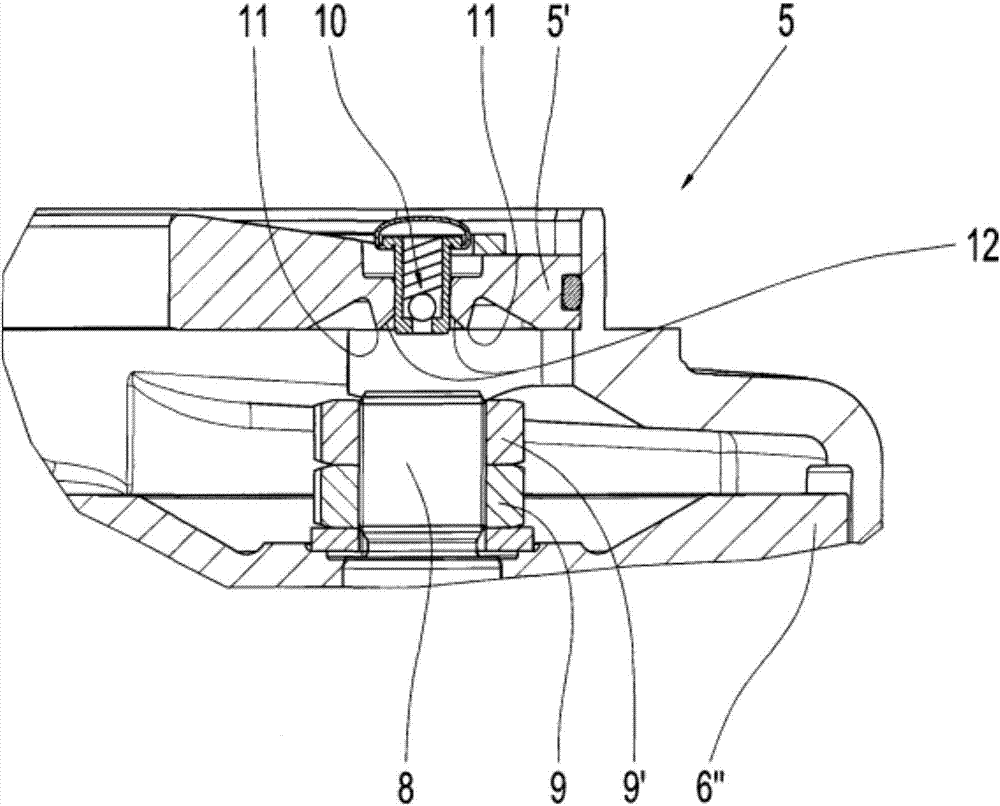

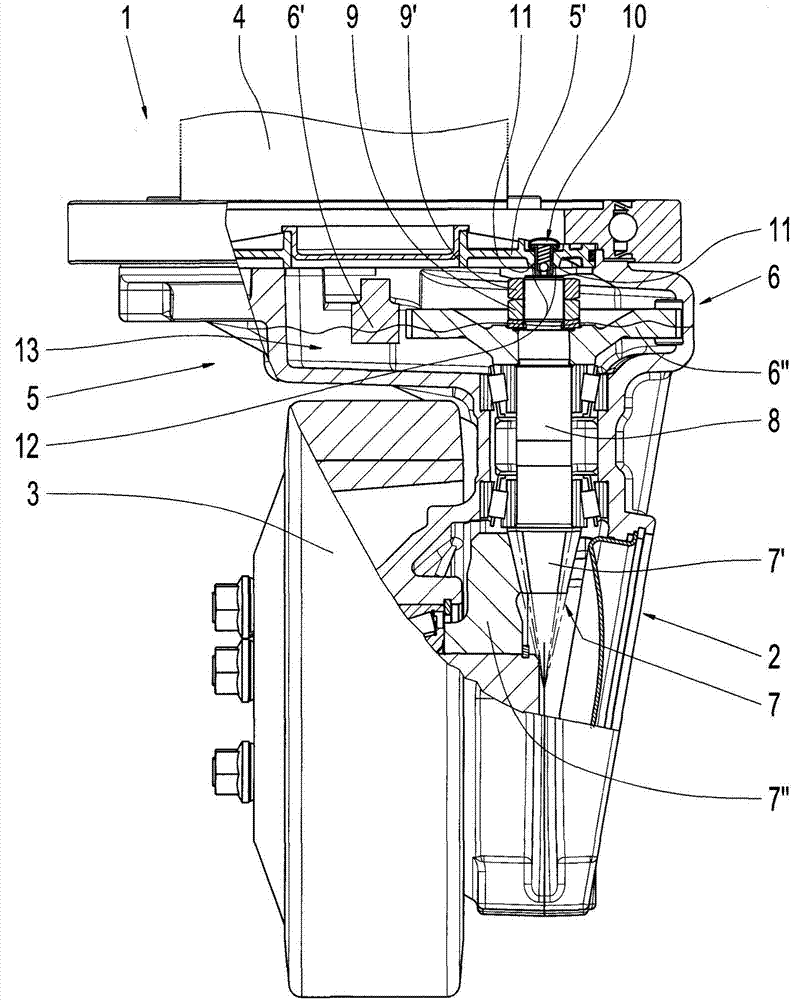

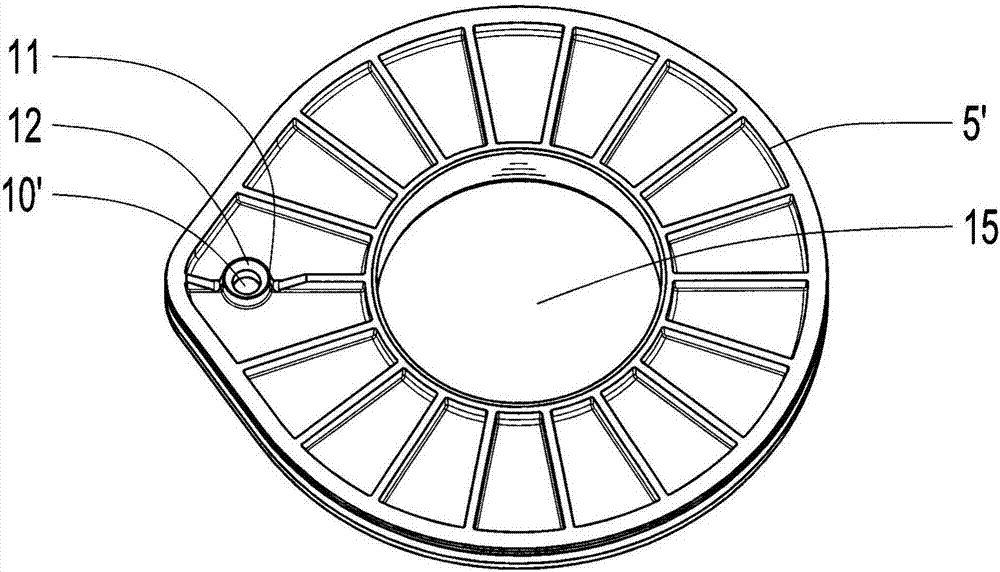

[0036] figure 1 A possible embodiment of the transmission housing 5 according to the invention is shown only partially by way of example. Here, in particular, an upper housing wall 5' can be seen, which has a venting device 10 configured as a spring-loaded non-return valve 10. As can be seen, the exhaust means 10 passes through the upper housing wall 5' from the inside to the outside of the upper housing wall 5'. In this case, directly adjacent to the exhaust device 10, a drip edge 11 is provided on the inner side of the upper housing wall 5', which frames the exhaust device 10 annularly. as by figure 1 It can also be seen from the view that the drip edge 11 is configured as a surface profile on the inner side of the upper housing wall 5', so that it appears as a thorn-like protrusion in the depression 12. According to the example, the depression 12 and the drip edge 11 frame the exhaust device 10 annularly. If, during operation of the drive unit 1 to which the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com