Separating device for a battery module, battery module, and motor vehicle

A separation device, battery module technology, applied in the direction of battery/battery traction, electric vehicles, batteries, etc., can solve problems such as battery module damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The examples set forth below are preferred embodiments of the invention. In the exemplary embodiments, the described components of an embodiment correspond to individual features of the invention which can be considered independently of one another and which respectively also develop the invention independently of one another. Therefore, the present disclosure shall also include combinations of the embodiments other than the combinations shown. Furthermore, the described embodiments can also be supplemented by other features of the invention which have already been described.

[0042] In the figures, identical reference numerals denote corresponding functionally identical elements.

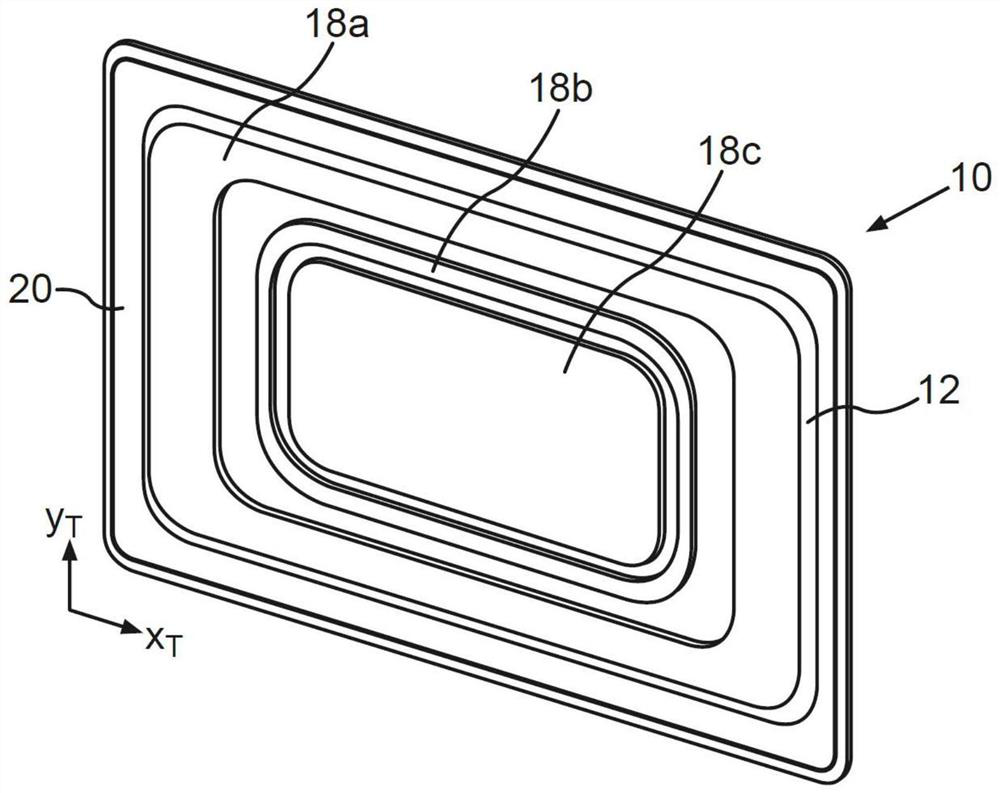

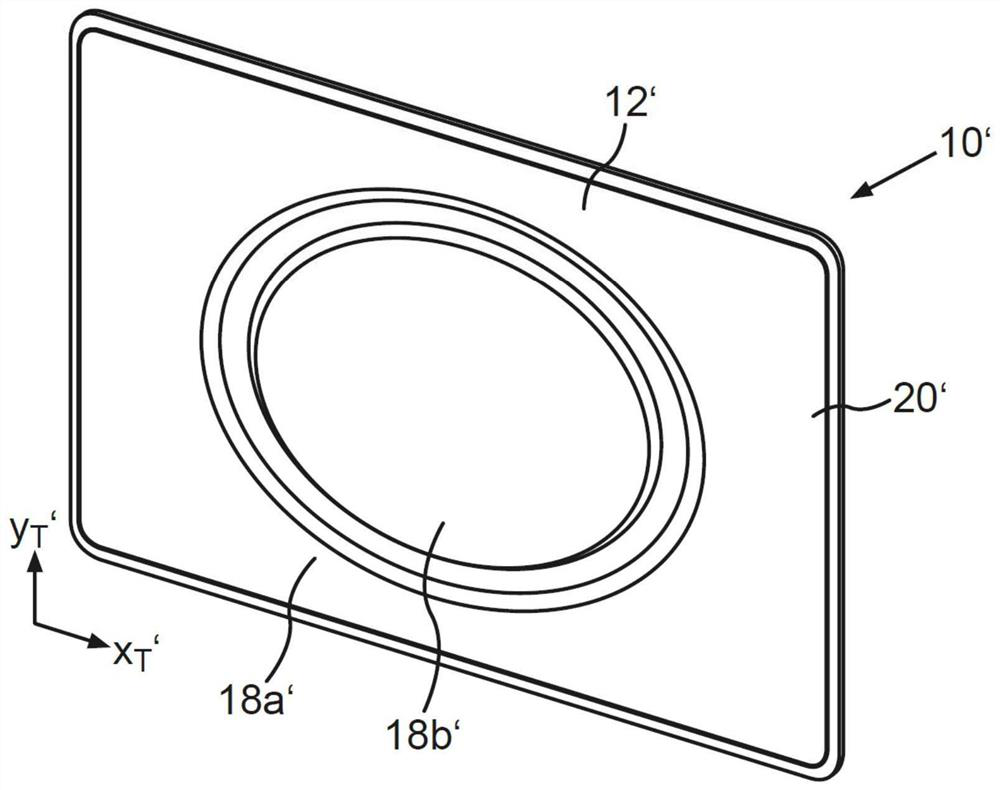

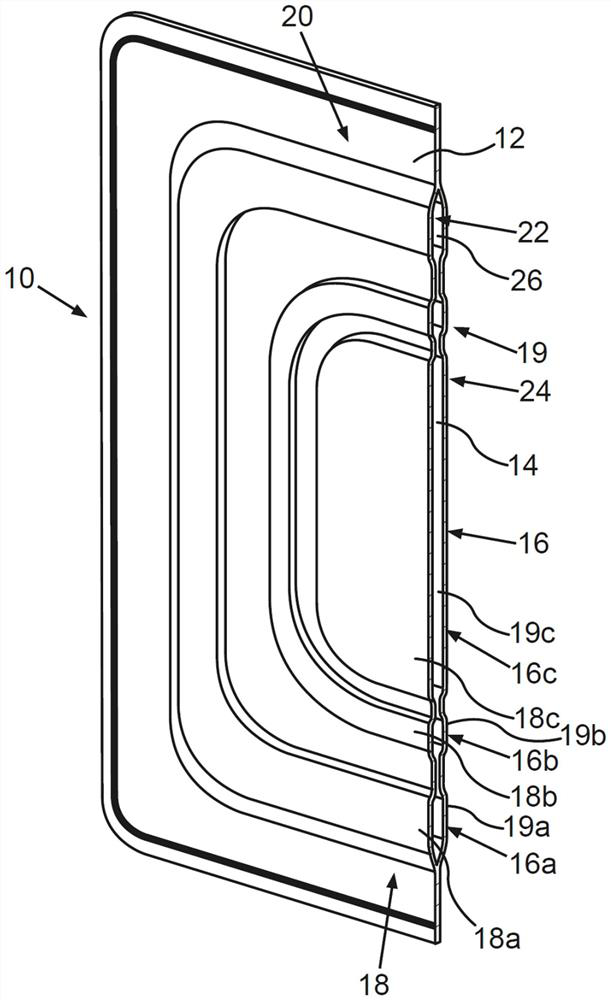

[0043] figure 1 is shown in perspective view for the battery module (in figure 1 not shown in) the separator 10. figure 2 An alternative embodiment of the separating device 10' is shown. image 3 shown in cutaway figure 1 The partition device 10. In the following, combined Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com