Regulating device and method for drying and temperature regulation of ballast bed

A technology of adjusting device and ballast bed, applied in the direction of road, track, ballast layer, etc., to avoid short-circuit flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

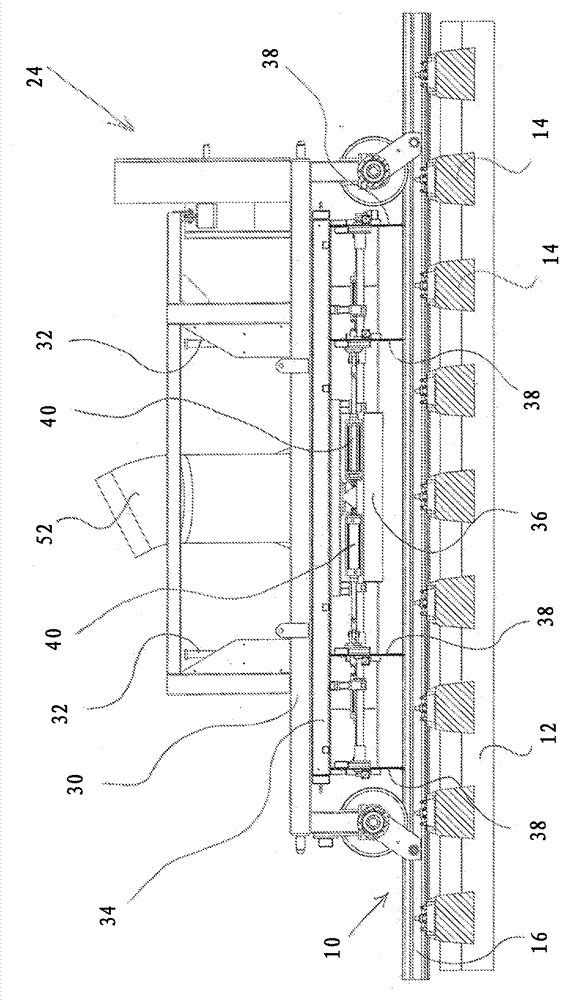

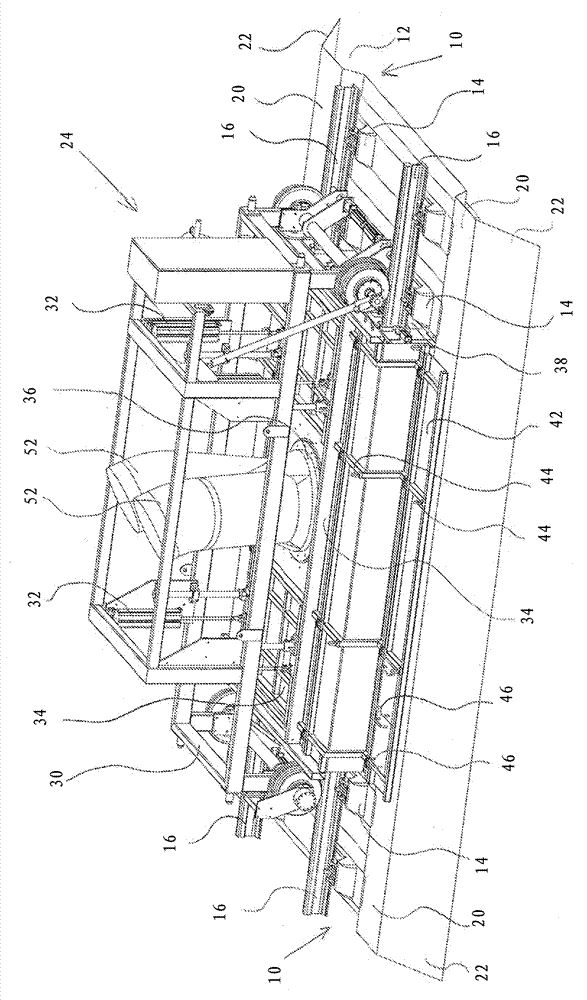

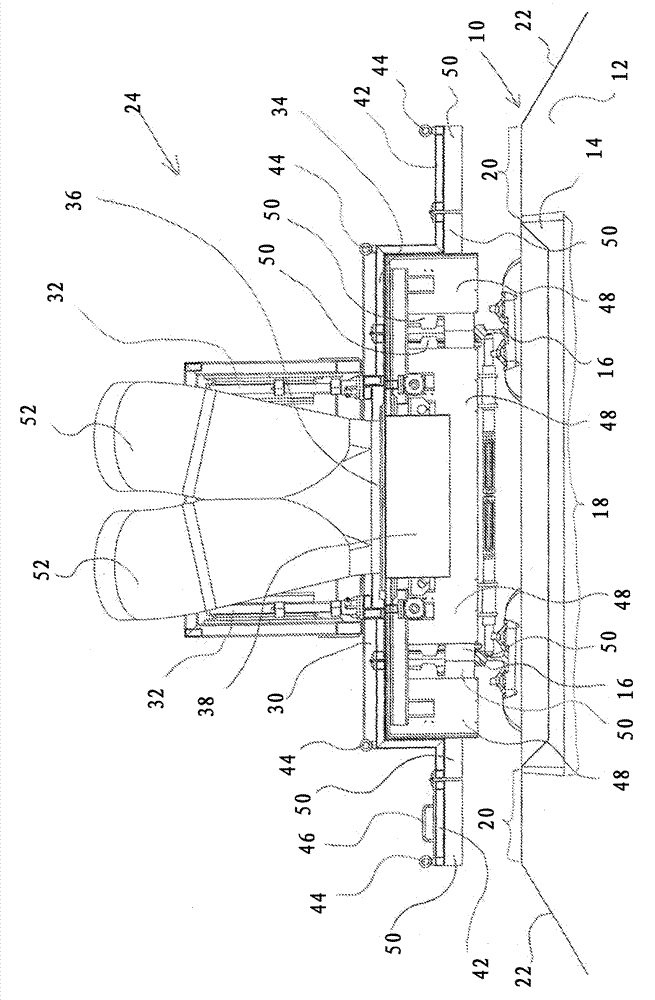

[0022] exist figure 1 The railway track arrangement 10 shown in FIG. 2 has a track bed 12 on which a plurality of sleepers 14 are placed. The crossties 14 support two rails 16 which are arranged at a distance from one another corresponding to the intended gauge. The area between two sleepers 14 is called the "tie compartment". The sleepers 14 are placed on the track bed 12 in the bearing region 18 . Next to the crossties 14 , the track bed 12 has a shoulder 20 oriented approximately horizontally. A ramp surface 22 running substantially obliquely upwards or in most cases downwards adjoins the shoulder 20 . exist Figures 2 to 5 The adjusting device 24 shown in the figure can blow tempered air between the rails 16 and in the shown embodiment on both sleeper compartments in the blowing area 26 . Around the blow-in region 26 , the regulating device 24 can prevent the tempered air from flowing out of the ballast bed 12 in the covering region 28 .

[0023] as in figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com