Drive wheel for crawler running gear

A technology of walking mechanism and driving wheel, which is applied in the direction of motor vehicles, tracked vehicles, transportation and packaging, etc. It can solve the problems of track damage and costly maintenance work, and achieve the effect of avoiding high wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

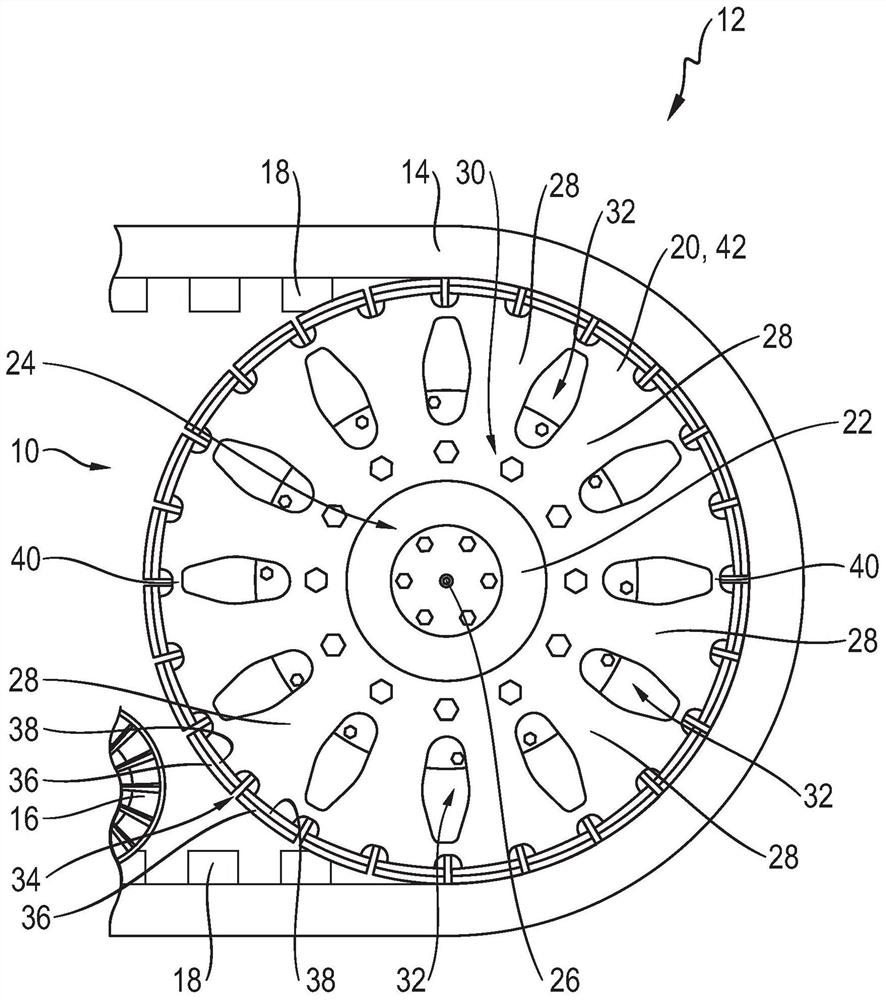

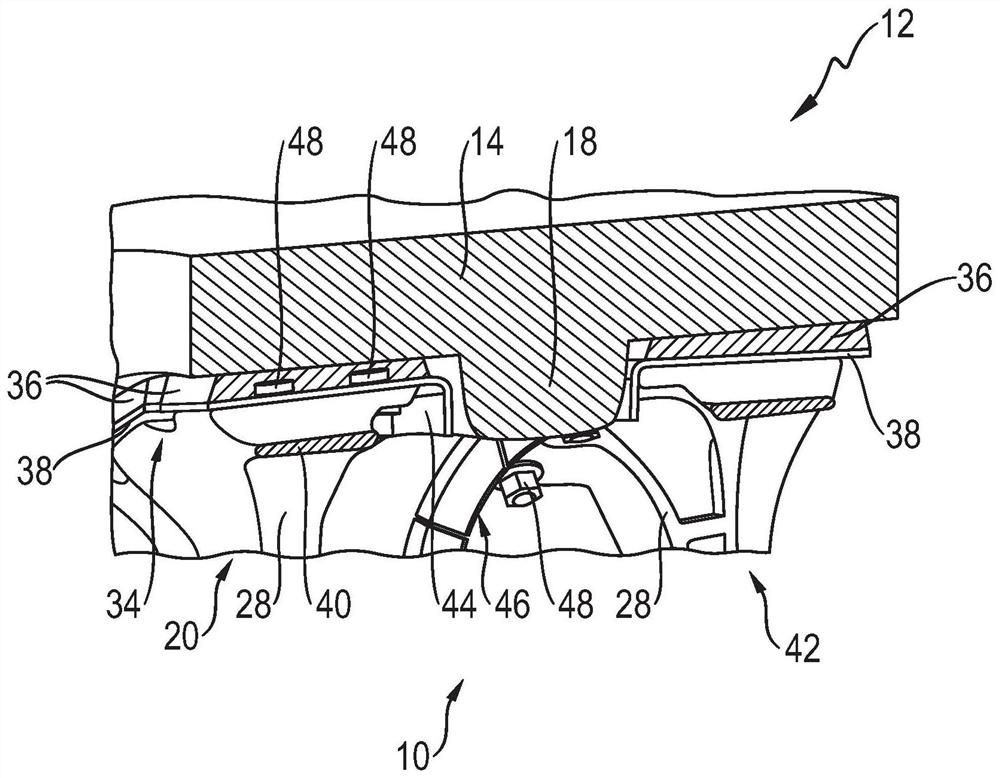

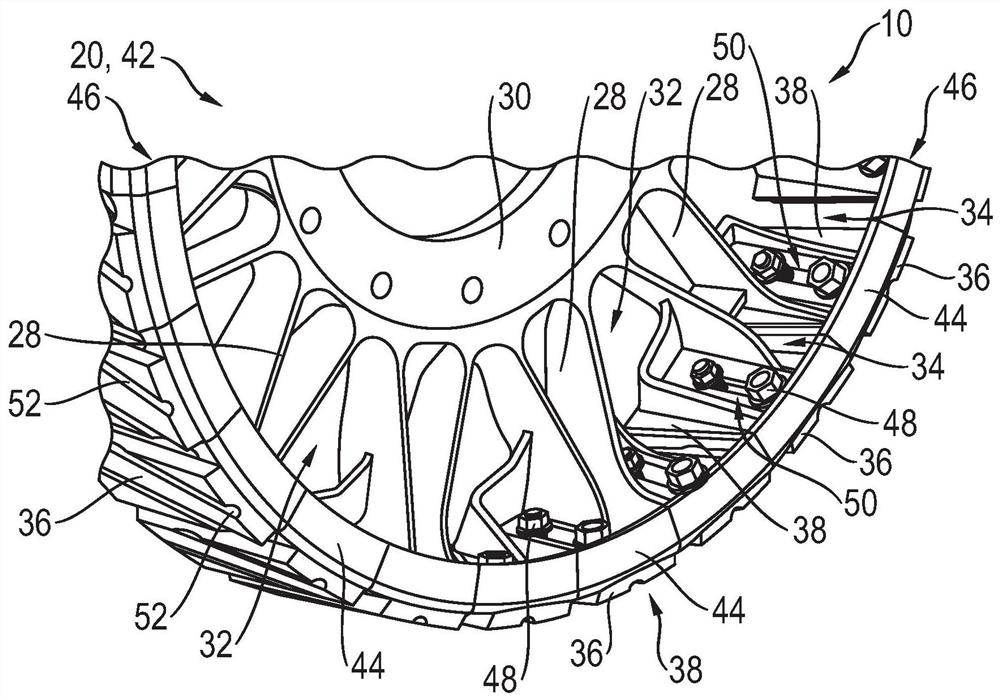

[0022] exist figure 1 A drive wheel 10 of a crawler 12 of an agricultural work machine such as a tractor (not shown) is shown. The construction of a crawler-type running gear with elastic tracks will not be described in detail, as this is considered to be known to those skilled in the art. A working machine in the sense of the present invention can also be a construction machine with a crawler-type running gear, or a self-propelled harvester, such as a combine harvester or a forage harvester.

[0023] In order to support the agricultural working machine relative to the ground, the crawler 12 has elastic crawler belts 14 , which are made of rubber, for example, which loop endlessly. The crawler 14 is here driven by a drive pulley 10 , placed in a rotary motion and run by at least one working roller (not shown) and a support roller 16 , at which the crawler 14 is turned, by means of which the working machine can pass Supported relative to the ground. The drive of the crawler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com