A kind of heavy calcium carbonate powder surface modification method

A technology of heavy calcium powder and heavy calcium powder, applied in the field of polymer chemistry and physics, can solve the problems of easy aggregation of nanoparticles, affecting the performance of composite materials, affecting the use of materials, etc., and achieves simple process, excellent performance indicators and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

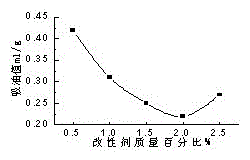

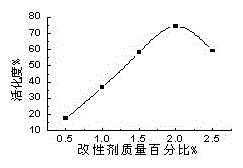

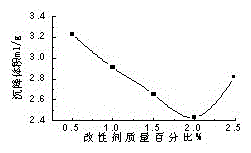

[0083] The influence of embodiment 1 modifier concentration on the modification of heavy calcium particles

[0084] Toluene is used as the solvent (the solvent is dried by calcium hydride reflux to remove moisture), and the heavy calcium powder is dried at 100°C for 4 hours to remove moisture. The amount of solvent toluene is about 100 parts, and the heavy calcium powder is 10 parts. Maleic anhydride, acrylamide, methyl methacrylate (monomers are all industrial grade) about 0.1 parts in total (1% of the mass of heavy calcium powder), dissolved in a little N,N dimethylformamide (DMF) , and then add it to a reaction eggplant-shaped bottle (protected by inert gas nitrogen), add a polytetrafluoroethylene magnetic stirrer to stir, the temperature should be 80°C, the stirring speed should be 500r / min, and the reaction time should be 90min, filter and vacuum dry to remove The solvent can be used to obtain the active heavy calcium powder after the first modification, in order to pre...

Embodiment 2

[0093] The influence of embodiment 2 modifier time on the modification of heavy calcium particles

[0094] For the first modification reaction conditions, toluene is used as the solvent (the solvent is refluxed and dried with calcium hydride to remove moisture), and the heavy calcium powder is dried at 100°C for 4 hours to remove moisture. The amount of solvent toluene is about 100 parts. 10 parts of heavy calcium powder, monomer maleic anhydride, acrylamide, methyl methacrylate (monomers are all industrial grade) about 0.1 parts (1% of the weight of heavy calcium powder) in total, with a little N, N Methylformamide (DMF) was dissolved, then added to a reaction eggplant-shaped bottle (protected by inert gas nitrogen), and stirred with a polytetrafluoroethylene magnetic stirring bar. The temperature should be 90°C, the stirring speed should be 500r / min, and the reaction time Respectively 60min, 90min, 120min, 150min, 180min, filter, vacuum dry to remove the solvent to obtain th...

Embodiment 3

[0103] The influence of embodiment 3 modification temperature on the modification of heavy calcium particles

[0104] For the first modification reaction conditions, toluene is used as the solvent (the solvent is refluxed and dried with calcium hydride to remove moisture), and the heavy calcium powder is dried at 100°C for 4 hours to remove moisture. The amount of solvent toluene is about 100 parts. 10 parts of heavy calcium powder, monomer maleic anhydride, acrylamide, methyl methacrylate (monomers are all industrial grade) about 0.1 parts in total (1% of the weight of heavy calcium powder), with a little N, N Methylformamide (DMF) was dissolved, then added to a reaction eggplant-shaped bottle (protected by inert gas nitrogen), and stirred with a polytetrafluoroethylene magnetic stirring bar, and the reaction temperatures were 75°C, 80°C, 85°C, and 90°C , 95°C, add modifier concentration mass ratio of 0.2 parts (2% of the heavy calcium powder), the stirring speed is 500r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com