Wash-free soldering flux for leadless low-temperature soldering paste and preparation method thereof

A no-cleaning, flux technology, applied in the direction of welding equipment, welding media, manufacturing tools, etc., can solve the problems of continuous printing accuracy, printing speed, printing performance degradation, fast volatilization speed, etc., to achieve excellent fluidity, Effect of good application properties, good print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

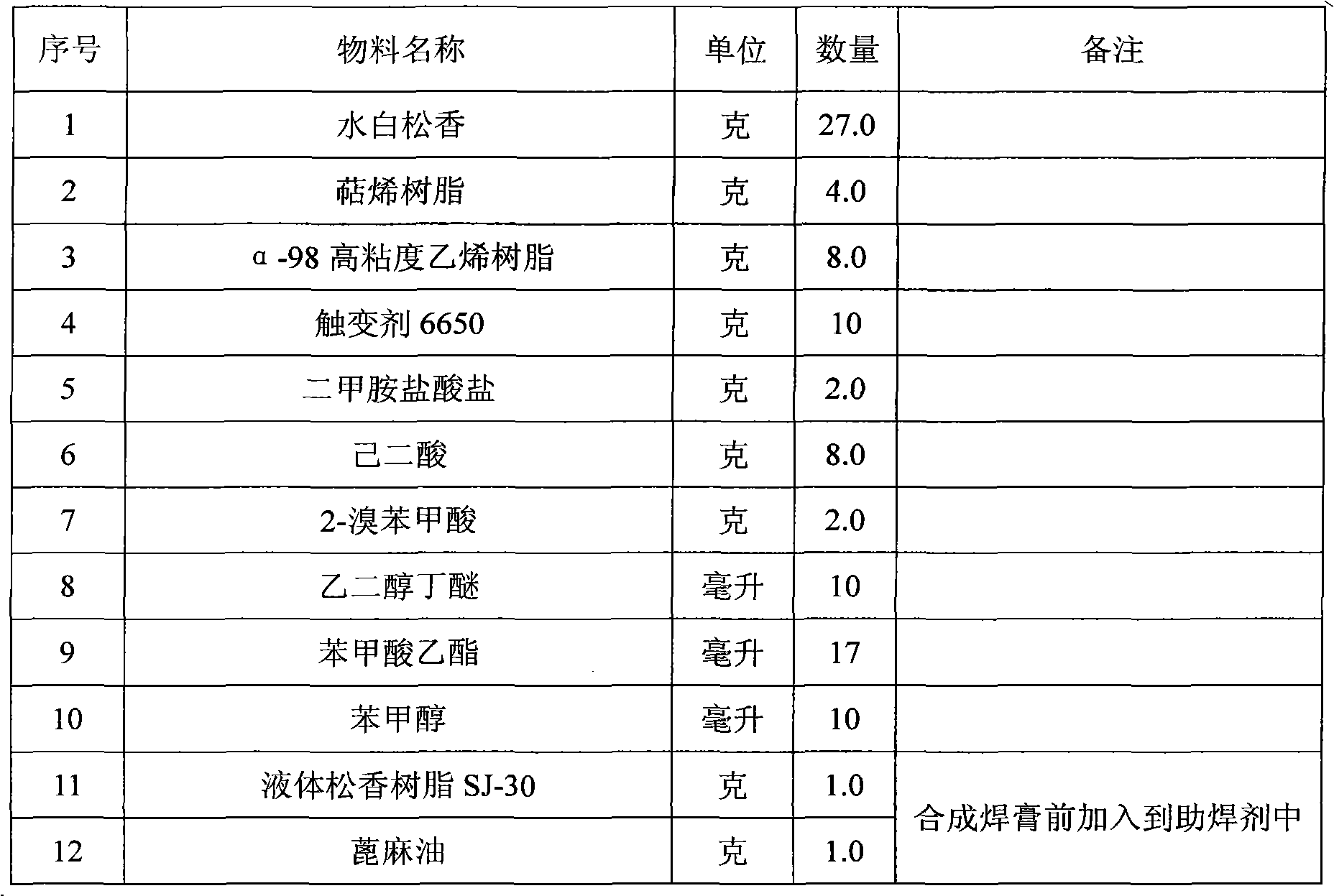

[0030] Each component and its content in the no-clean flux for lead-free low-temperature solder paste per 100 grams are:

[0031] serial number

Embodiment 2

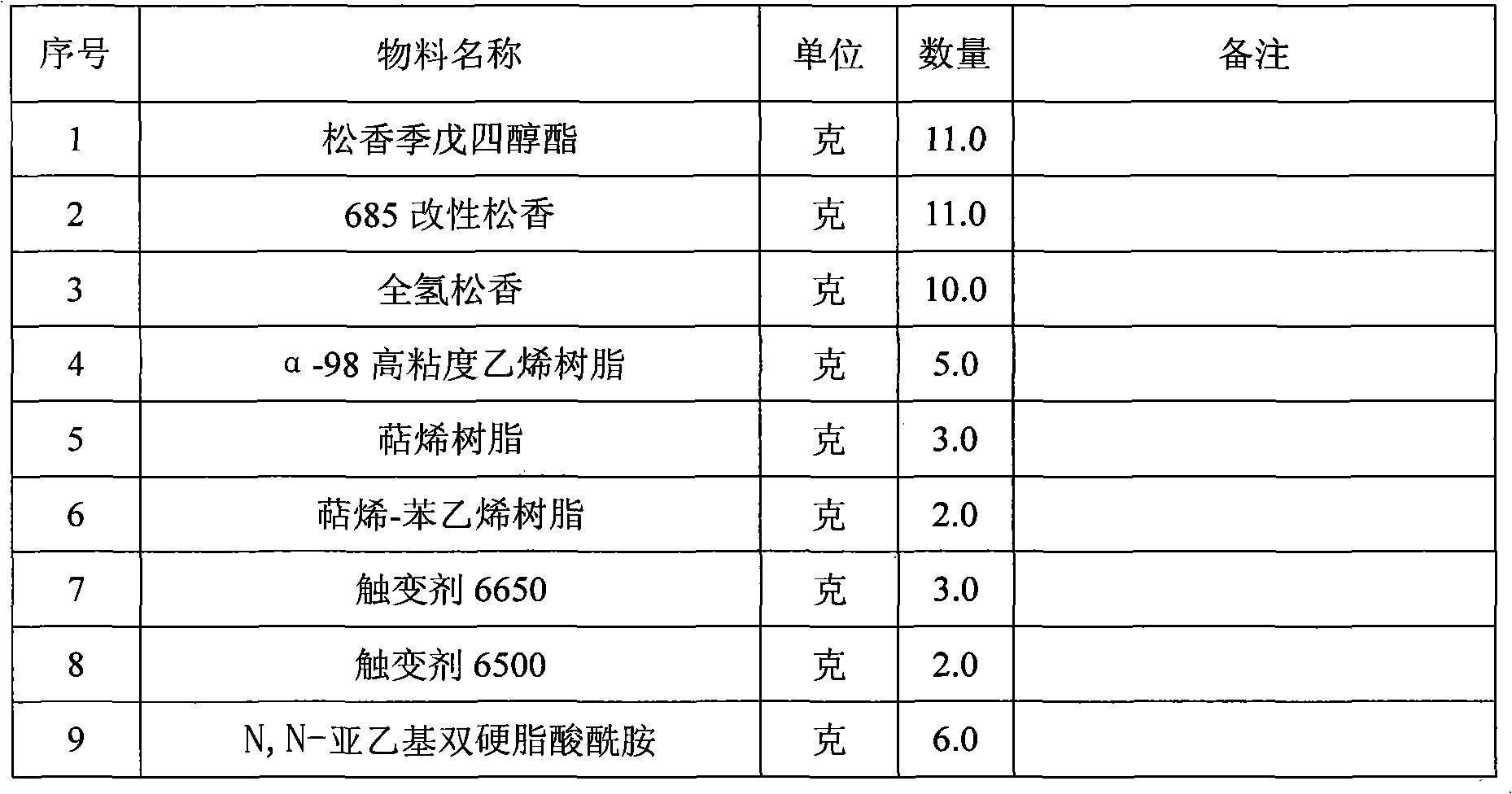

[0033] Each component and its content in the no-clean flux for lead-free low-temperature solder paste per 100 grams are:

[0034] serial number

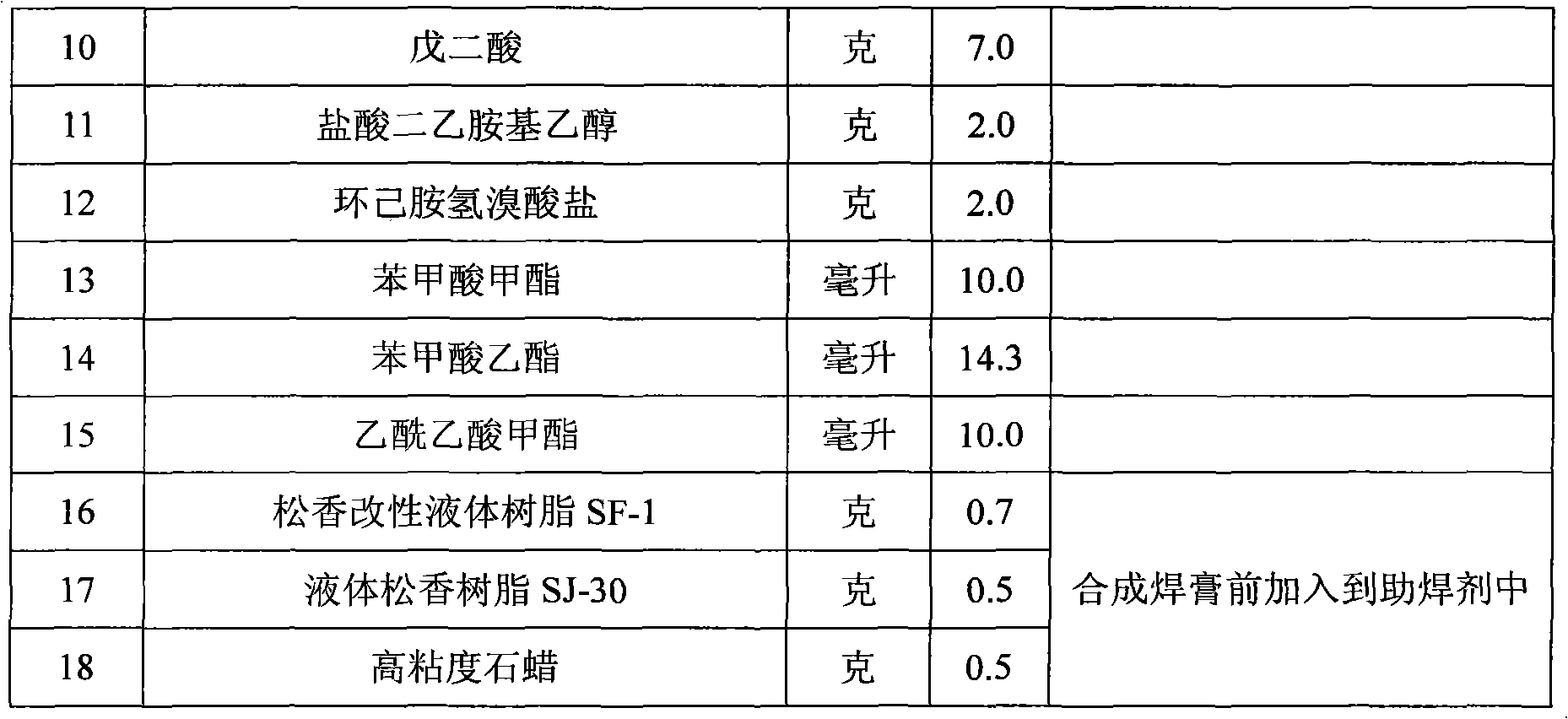

[0035] 10

Embodiment 3

[0037] Each component and its content in the no-clean flux for lead-free low-temperature solder paste per 100 grams are:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com