Preparation method of polyanionic cellulose

A technology of polyanion and cellulose, applied in the field of preparation of polyanion cellulose, can solve the problems of poor salt tolerance and poor water loss resistance, and achieve the effects of good salt tolerance, low cost and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

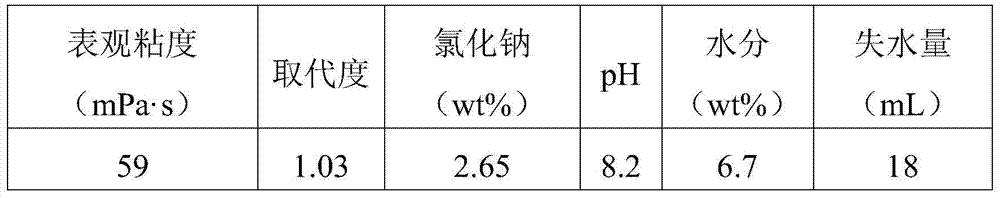

Embodiment 1

[0041] The preparation method of the polyanionic cellulose of the present embodiment, it may further comprise the steps:

[0042] (1) In a kneader, mix 1215g of NaOH aqueous solution with a concentration of 50.2% (w / w) and 1626g of an aqueous ethanol solution with a concentration of 92% (v / v), and cool it to 10-35 ℃; the mass ratio of the NaOH aqueous solution to the ethanol aqueous solution is 1:1.338; 1000 g of refined cotton cellulose with a degree of polymerization of 2820 after shredding is put into a kneader to obtain a mixture A; Carry out alkalization reaction at 15-40°C, and obtain alkali cellulose after 50 minutes of reaction; the mass ratio of the refined cotton cellulose to the ethanol aqueous solution is 1:1.626;

[0043] (2) Mix 850g of 70% (w / w) ethanol aqueous solution of chloroacetic acid with alkali cellulose by spraying within 25 minutes. The mixing temperature is controlled within 15-40°C, and the concentration of ethanol aqueous solution is 92% (v / v), mix...

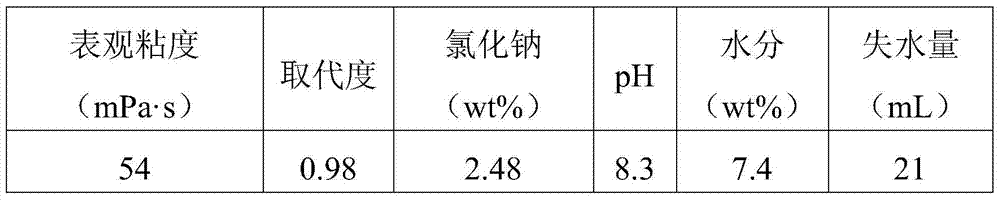

Embodiment 2

[0058] The preparation method of the polyanionic cellulose of the present embodiment, it may further comprise the steps:

[0059] (1) Mix 1267g of NaOH aqueous solution with a concentration of 50.2% (w / w) and 1788.6g of an aqueous ethanol solution with a concentration of 91.5% (v / v) in a kneader, and cool it down to 10°C with cooling water -35°C; the mass ratio of the NaOH aqueous solution to the ethanol aqueous solution is 1:1.412; 1000 g of refined cotton cellulose with a polymerization degree of 2430 after shredding is put into a kneader to obtain a mixture A ; carry out alkalization reaction at 15-40°C, and obtain alkali cellulose after 50 minutes of reaction; the mass ratio of the refined cotton cellulose to the ethanol aqueous solution is 1:1.789;

[0060] (2) Mix 1030g of chloroacetic acid aqueous ethanol solution with a concentration of 62% (w / w) and alkali cellulose by spraying within 25 minutes. The mixing temperature is controlled within 15°C-40°C. The concentration...

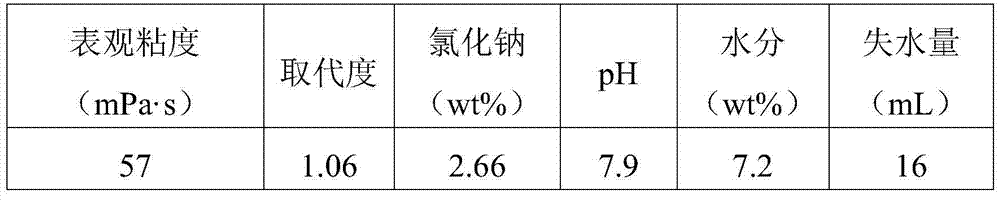

Embodiment 3

[0073] The preparation method of the polyanionic cellulose of the present embodiment, it may further comprise the steps:

[0074] (1) In a kneader, mix 1334g of NaOH aqueous solution with a concentration of 48.6% (w / w) and 2276.4g of an aqueous ethanol solution with a concentration of 93.5% (v / v), and cool it to 10- 35°C; the mass ratio of the NaOH aqueous solution to the ethanol aqueous solution is 1:1.706; put 1200g of wood pulp cellulose after crushing into the kneader to obtain the mixture A; at 15-40°C Perform an alkalization reaction, and obtain alkali cellulose after reacting for 50 minutes; the degree of polymerization of the wood pulp cellulose is 1100; the mass ratio of the wood pulp cellulose to the ethanol aqueous solution is 1:2.276;

[0075] (2) Mix 818g of ethanol aqueous solution of chloroacetic acid with a concentration of 76% (w / w) and alkali cellulose by spraying within 25 minutes. The mixing temperature is controlled within 15-40°C, and the concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com