A capacitive connection structure to reduce inductance

A connection structure and capacitance technology, which is applied to multiple fixed capacitors and parts of fixed capacitors, can solve problems such as capacitor damage, large unbalance, and circuit unbalance, and achieve current stability, self-inductance reduction, and circuit balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

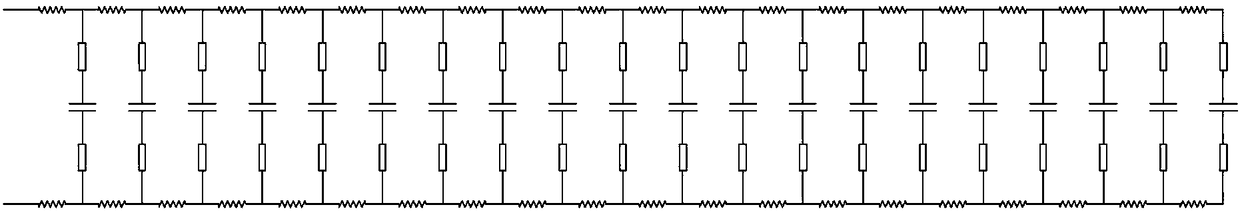

[0023] A capacitive connection structure for reducing inductance, comprising layered stacked capacitor cores and bus bars for connecting the capacitor cores.

[0024] The top and bottom of each capacitor core are respectively provided with an upper busbar and a lower busbar. The shape and structure of the upper and lower busbars are the same, and the installation direction is opposite. The lower busbar is vertically flipped over the upper busbar. One end of the busbar is the lead-out part, which is used to connect the positive and negative lead-out wires. A connecting portion is provided in the middle of the busbar for connecting the capacitor core. The connection parts of the upper and lower busbars are respectively connected with the gold-sprayed surfaces on both sides of the capacitor core of this layer, forming a layer of capacitor connection structure. According to the requirement of capacitance capacity, the internal structure of the power capacitor is formed by stacki...

Embodiment 2

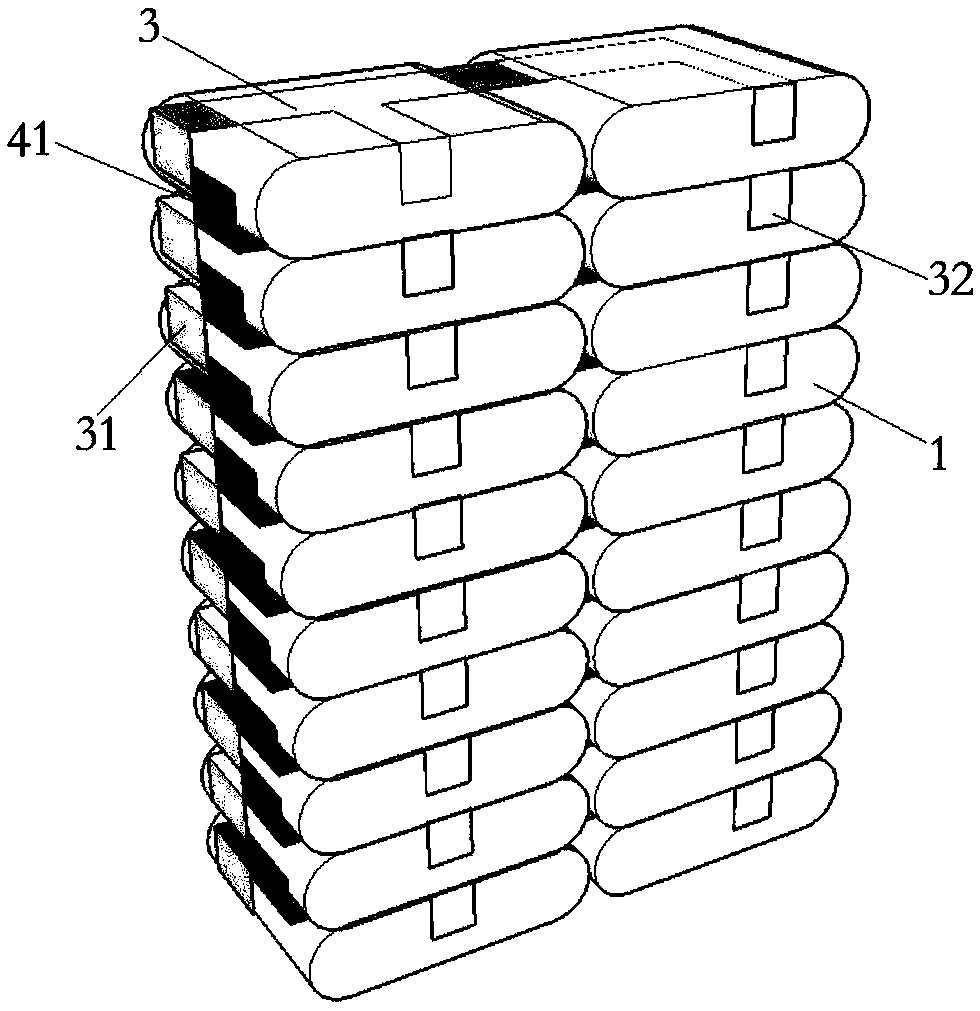

[0027] Such as image 3 and Figure 4 As shown, a capacitor connection structure for reducing inductance is formed by stacking multilayer capacitor cores 1. The capacitor connection structure has 10 layers in total, each layer has two flat capacitor cores 1, and the capacitor cores in each layer Sub-1s are connected through busbars.

[0028] Such as Figure 5 As shown, the top of each capacitor core 1 is provided with an upper busbar 3, and the bottom is provided with a lower busbar 4 vertically turned over from the upper busbar 3. One end of the busbar is provided with a lead-out bend, and the middle part is provided with two connection bends, which are respectively used to connect the two capacitor cores 1 of this layer. The bending directions of the lead-out bends and the connection bends are the same. The connection bend 32 of the upper busbar is connected to the gold-sprayed solder spot on one side of the capacitor core 1, and the connection bend 42 of the lower busbar...

Embodiment 3

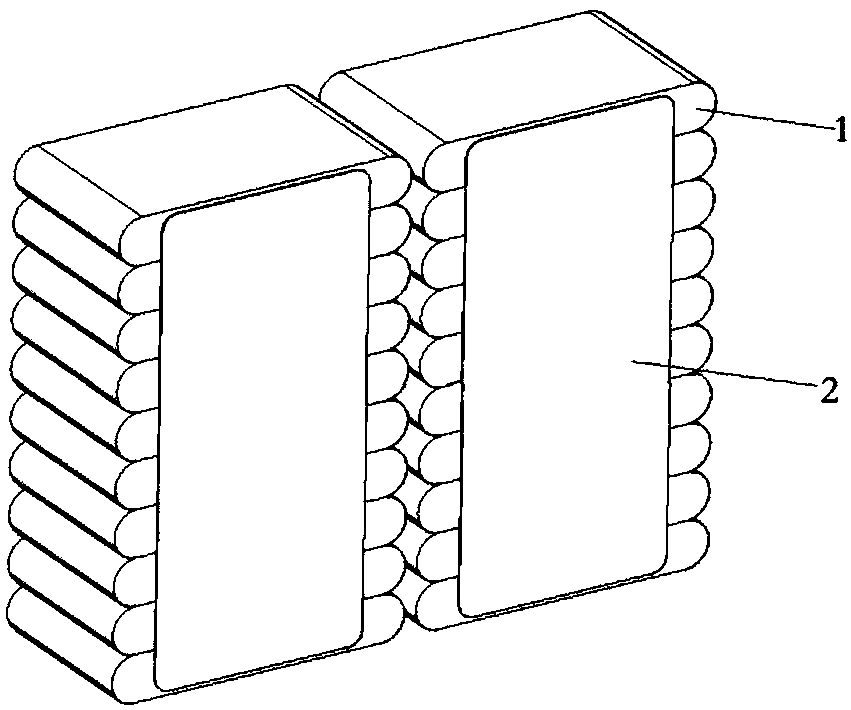

[0032] The difference between this embodiment and the foregoing embodiments lies in that the shape of the capacitor core is cylindrical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com