Polyethylene film adhesion tape and preparation method thereof

A technology of polyethylene film and adhesive tape, which is applied in the direction of film/flaky adhesives, adhesives, pre-treated surfaces, etc., can solve the problems of high raw material prices, affecting the life of main insulation, and difficulty in forming cost competitive advantages. To achieve the effects of short production cycle, good performance and cost competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The polyethylene film is UHMW-PE ultra-high molecular weight polyethylene film from Yangzhong Shuguang Fluoroplastic Co., Ltd.; the adhesive is DS160 adhesive from Shenzhen Shili Adhesive Co., Ltd.

[0017] Preheat the oven of the glue applicator, heat and maintain the temperature at 100°C; put the adhesive into the glue tank of the glue applicator, and complete the preparation work.

[0018] Guide the polyethylene film to the guide roller of the gluing machine, and then start gluing, use a rubber roller to roll on the surface of the film on one side for gluing, and then scrape the surface of the film coated with glue with the squeegee; The part is transported to the oven by the guide roller; after the pressure roller is released, it is directly wound and cut to obtain the product. During the process, the film speed was 3m / min.

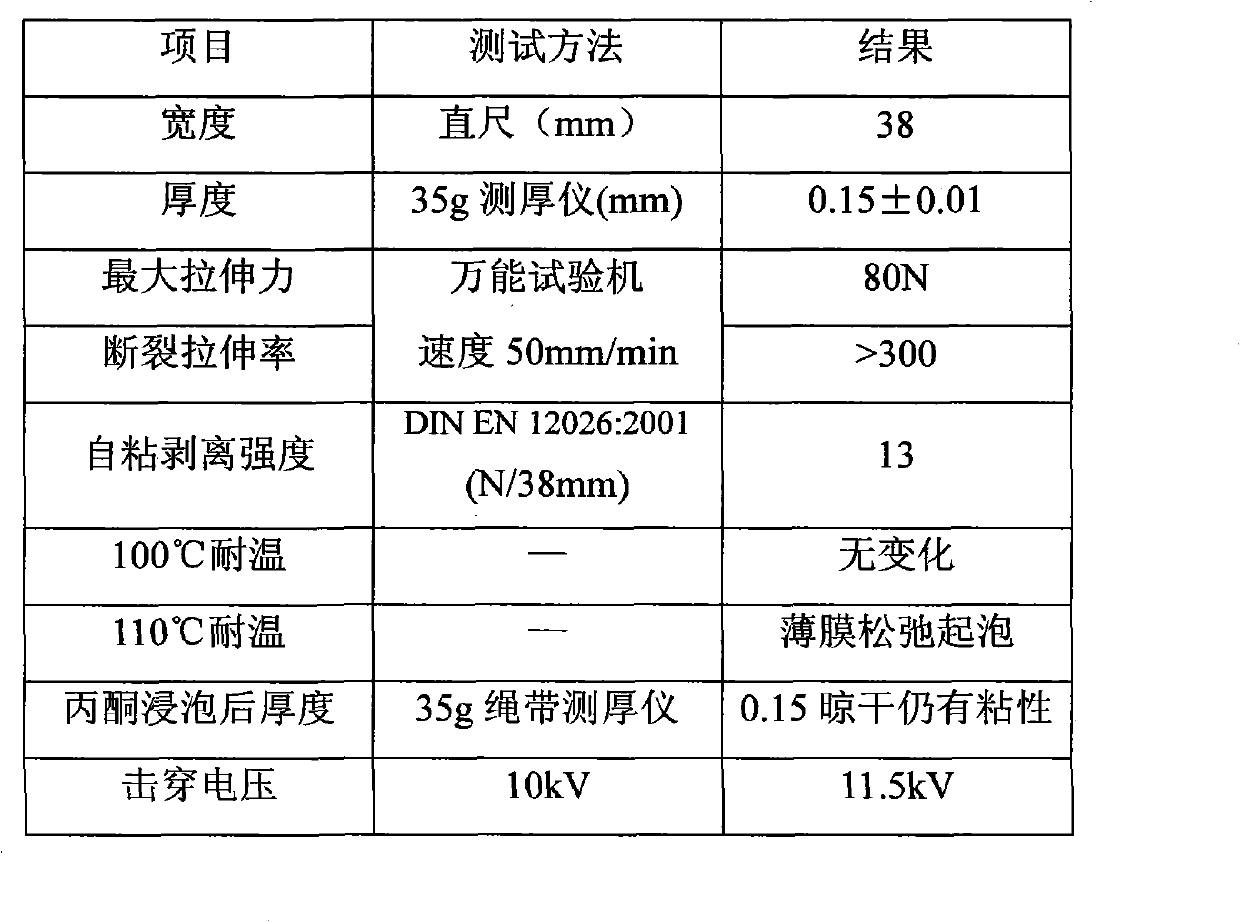

[0019] Prepared polyethylene film adhesive tape, test result is as follows:

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com