Preparation method of edible-grade sodium carboxymethylcellulose

A technology of sodium carboxymethyl cellulose and cellulose, which is applied in the field of preparation of food grade sodium carboxymethyl cellulose, can solve the problems of low purity, poor acid resistance, poor performance of sodium carboxymethyl cellulose, etc., and achieves superior performance. Effects of stability, lower production costs, and lower solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

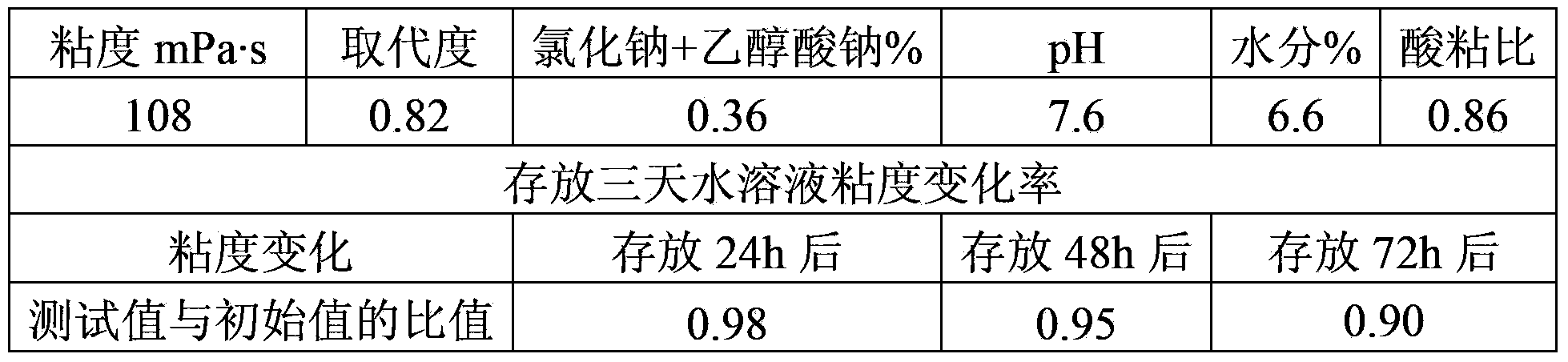

Examples

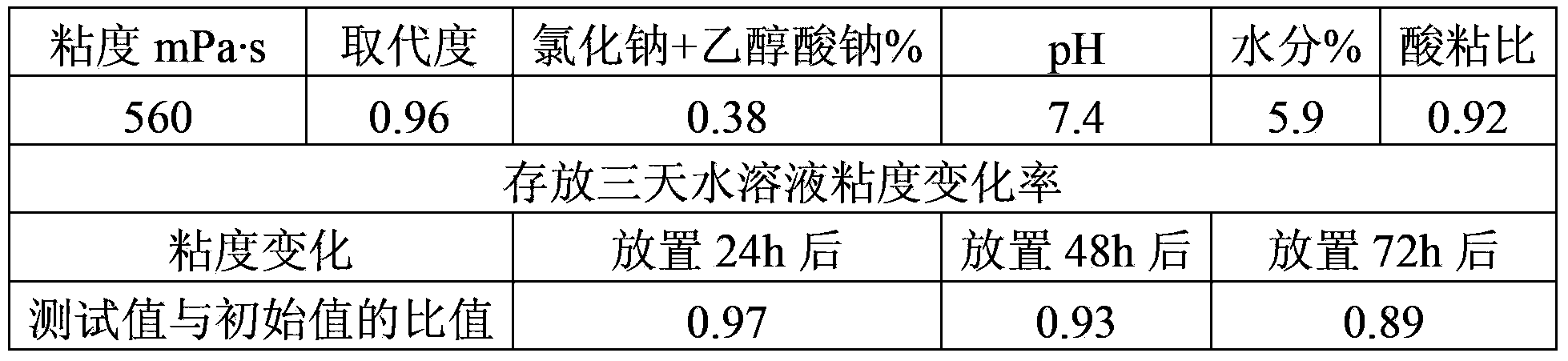

Embodiment 1

[0042] A preparation method of edible grade sodium carboxymethylcellulose, which comprises the steps of:

[0043] (1) Mix 1101g of NaOH aqueous solution with a concentration of 49.5wt% and 1400mL of ethanol solution with a concentration of 91v / v% in a kneader for 20min at 15-35°C, and put 1000g of refined cotton cellulose into the kneader, Obtain mixture A; then by spraying, 301g concentration of 49.5wt% NaOH aqueous solution and 1000ml concentration of 91v / v% ethanol solution mixed with lye and mixture A are mixed at 15-40°C Alkaline reaction for 50 minutes, after the reaction, alkalized cellulose is obtained;

[0044] (2) Mix 762g of 70wt% ethanol aqueous solution of chloroacetic acid with alkalized cellulose by spraying within 20 minutes, the mixing temperature is controlled within 15-40°C, and the concentration of ethanol aqueous solution is 91v / v% , stirred at a speed of 20rpm for 10min to obtain mixture B;

[0045] (3) Mix 381g of 70wt% ethanol aqueous solution of chlo...

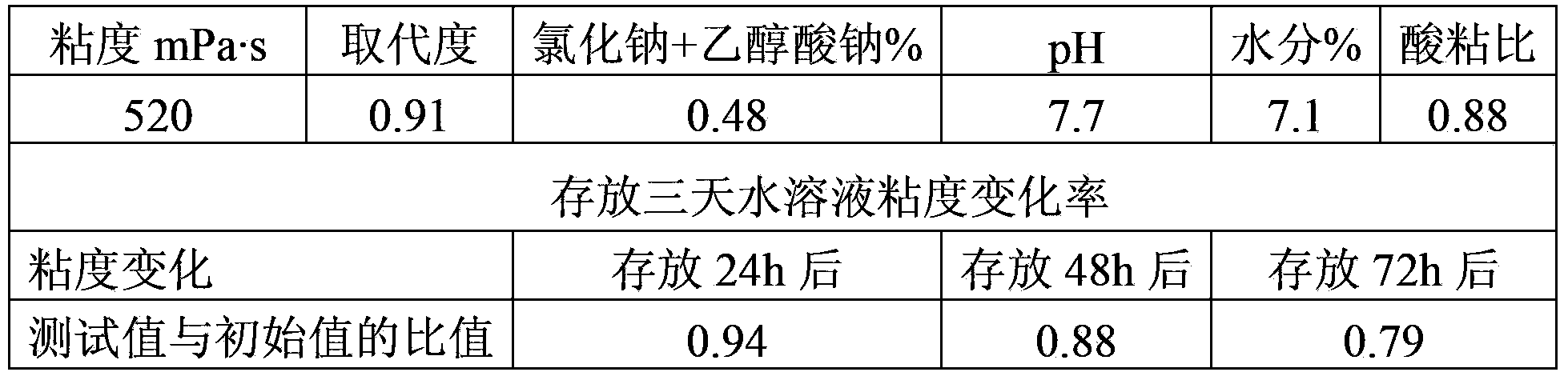

Embodiment 2

[0057] A preparation method of edible grade sodium carboxymethylcellulose, which comprises the steps of:

[0058] (1) Mix 873g of NaOH aqueous solution with a concentration of 50.2wt% and 1350mL of ethanol solution with a concentration of 90v / v% in a kneader for 30min at 15-35°C, and put 1000g of crushed wood pulp cellulose into the kneader In the machine, mixture A was obtained; then by spraying, 335g concentration of NaOH aqueous solution of 50.2wt% and 1000ml concentration of ethanol water solution of 91v / v% were mixed with mixture A, and mixed in 15-35 The alkalization reaction was carried out at ℃ for 50 minutes, and alkalized cellulose was obtained after the reaction;

[0059] (2) Mix 635g of ethanol aqueous solution of chloroacetic acid with a concentration of 75wt% and alkalized cellulose by spraying within 20 minutes, the mixing temperature is controlled within 15-40°C, and the concentration of ethanol aqueous solution is 95v / v% , stirred at a speed of 40rpm for 10mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com