Sliver alloy wire used for semiconductor packaging and preparation method thereof

A silver alloy and semiconductor technology, which is applied to the field of silver alloy wire for semiconductor packaging and its preparation, can solve the problems of short life, easy chip damage, and copper stability is not as good as gold, etc., and achieves the effect of low cost and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

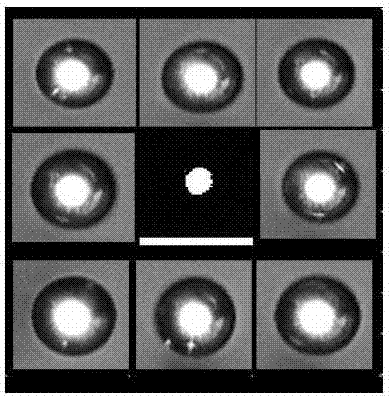

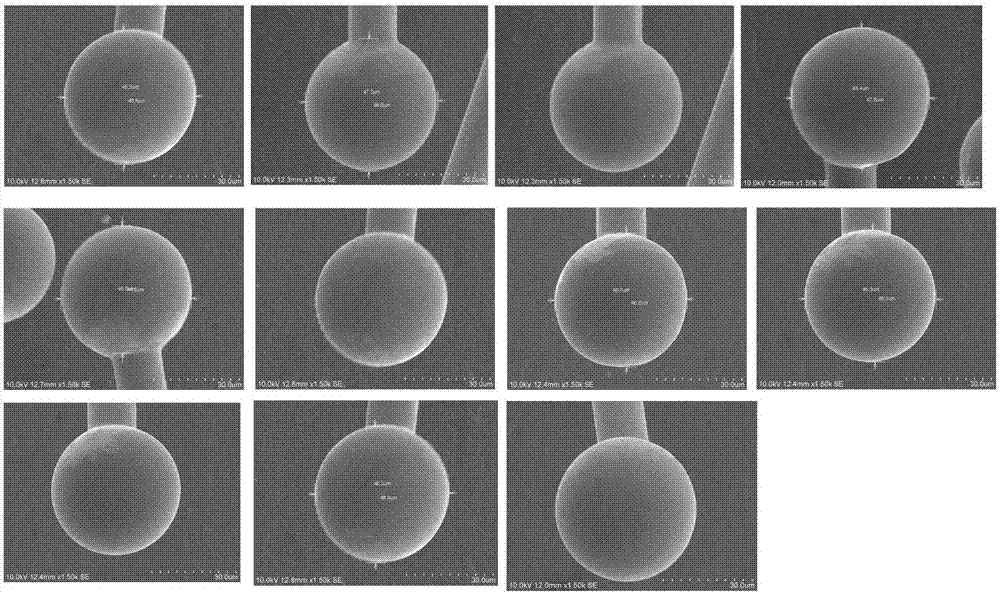

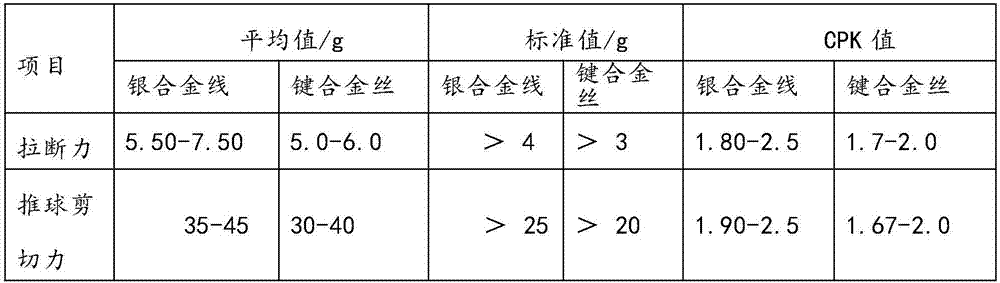

Image

Examples

Embodiment 1

[0027] a. Provide silver raw materials: purchase silver raw materials with a purity of 99.9% or more;

[0028] b. Electrolytic purification of silver raw materials: the electrolyte is silver nitrate solution (superior grade pure) diluted with high-purity water in a ratio of 1:4.5, the total required capacity is 50 liters; the coarse silver block is used as the anode (size is about 150mm×50mm×10mm) Immerse in the electrolyte, the monomer weight is 1000 grams, to ensure that 95% of the volume of the crude silver block is immersed in the electrolyte; high-purity silver foil or thin stainless steel plate (size 150mm×50mm×1mm) is immersed in the electrolyte as the cathode to ensure that the cathode sheet has 95% % Volume is immersed in the electrolyte, and the two poles are respectively connected to a DC power supply. Turn on the DC power supply, adjust the voltage to 6V, current 2.5A, and temperature control within 65℃. When the high purity silver (99.9995%) obtained from the cathode...

Embodiment 2

[0038] a. Provide silver raw materials: purchase silver raw materials with a purity of 99.9% or more;

[0039] b. Electrolytic purification of silver raw materials: the electrolyte is silver nitrate solution (superior grade pure) diluted with high-purity water in a ratio of 1:4.5, the total required capacity is 50 liters; the coarse silver block is used as the anode (size is about 150mm×50mm×10mm) Immerse in the electrolyte, the monomer weight is 1000 grams, to ensure that 95% of the volume of the crude silver block is immersed in the electrolyte; high-purity silver foil or thin stainless steel plate (size 150mm×50mm×1mm) is immersed in the electrolyte as the cathode to ensure that the cathode sheet has 95% % Volume is immersed in the electrolyte, and the two poles are respectively connected to a DC power supply. Turn on the DC power supply, adjust the voltage to 9V, the current 3.5A, and the temperature within 65℃. When the high purity silver (99.9995%) obtained from the cathode...

Embodiment 3

[0049] a. Provide silver raw materials: purchase silver raw materials with a purity of 99.9% or more;

[0050] b. Electrolytic purification of silver raw materials: the electrolyte is silver nitrate solution (superior grade pure) diluted with high-purity water in a ratio of 1:4.5, the total required capacity is 50 liters; the coarse silver block is used as the anode (size is about 150mm×50mm×10mm) Immerse in the electrolyte, the monomer weight is 1000 grams, to ensure that 95% of the volume of the crude silver block is immersed in the electrolyte; high-purity silver foil or thin stainless steel plate (size 150mm×50mm×1mm) is immersed in the electrolyte as the cathode to ensure that the cathode sheet has 95% % Volume is immersed in the electrolyte, and the two poles are respectively connected to a DC power supply. Turn on the DC power supply, adjust the voltage to 9V, the current 3.5A, and the temperature within 65℃. When the high purity silver (99.9995%) obtained from the cathode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com