Heat-resisting PVC high impact-resisting tubular product and preparation method thereof

A high-impact, PVC resin technology, used in pipes, rigid pipes, mechanical equipment, etc., can solve the problems of not excellent heat resistance, high raw material prices, and high production costs, and achieve high Vicat softening temperature and production technology. Simple, high extrusion speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The heat-resistant PVC high-impact resistance pipe is prepared by the following preparation process:

[0025] 1. Raw material compounding: mix 90 parts of QC-1050P PVC, 10 parts of CPVC (chlorine content 60%), 1.0 parts of organotin stabilizer, 5 parts of MBS additives, 5 parts of ACR additives, 3 parts of AS Additives, 0.5 parts of calcium stearate, 1.0 parts of PE wax, 0.2 parts of antioxidant 1010, 0.01 parts of carbon black and 1 part of nano-active calcium carbonate, add them to the high-speed mixer and mix for 10-15 minutes until When the mixing temperature is 100~130℃, put the material into the low-speed mixer, and discharge when the material temperature is cooled to 35~45℃;

[0026] 2. Pelletizing and extrusion molding: The mixed materials are pelletized by twin-screws. The temperature of the extruder is: zone 1 100℃, zone 2 120℃, zone 3 130℃, zone 4 140℃, zone 5 150℃ , The head is 150℃, and the pellets are extruded on the twin-screw extruder. The temperature of the...

Embodiment 2~5

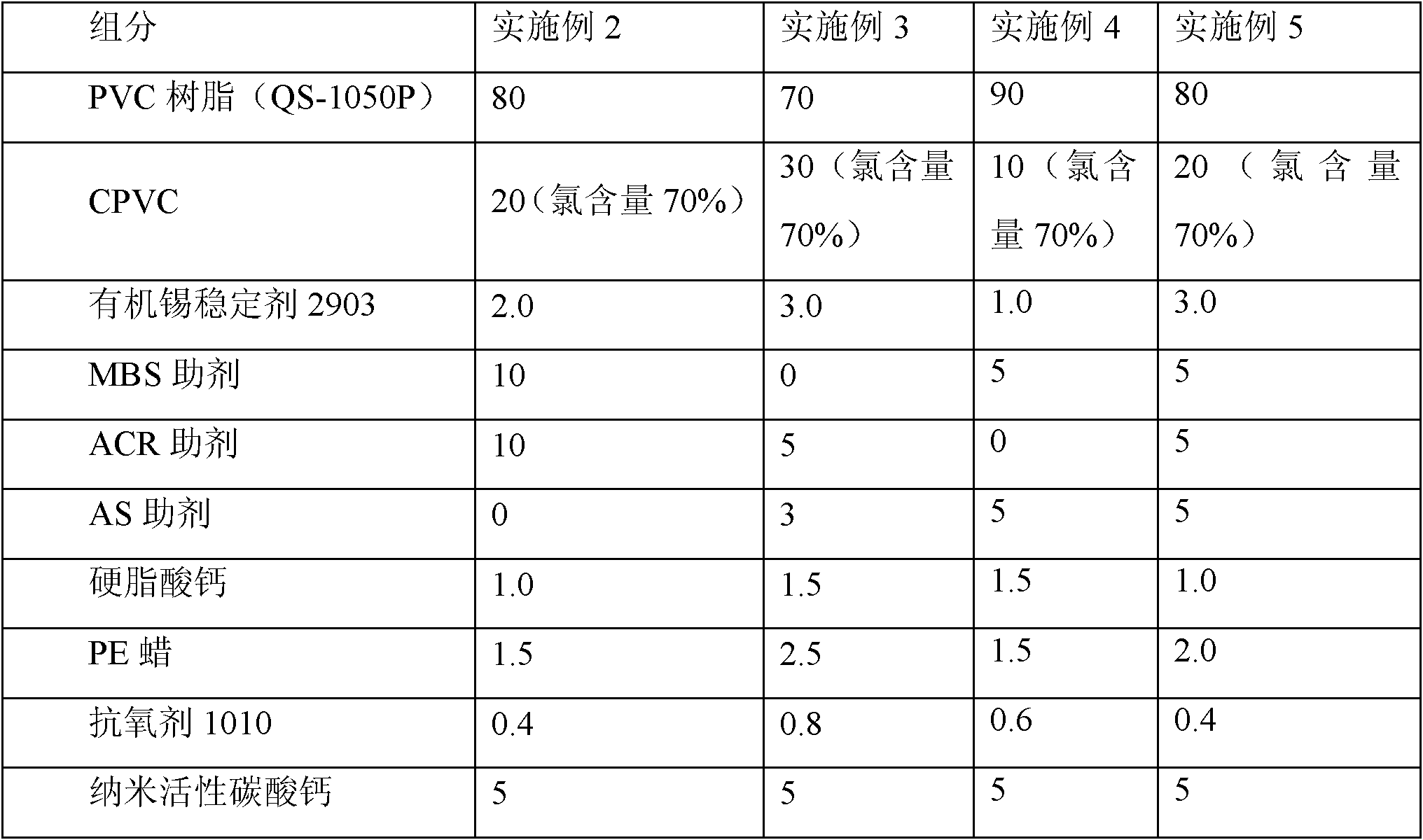

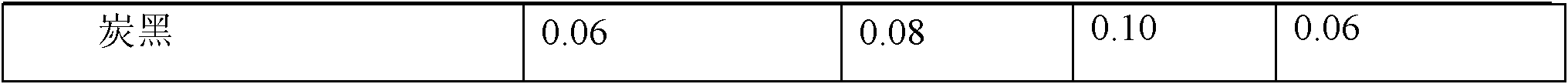

[0028] See Table 1 for the proportions of the compositions used in the pipes of Examples 2-5.

[0029] Table 1 The proportions of the compositions used in the pipes of Examples 2 to 5 (in parts by weight, unit: parts)

[0030]

[0031]

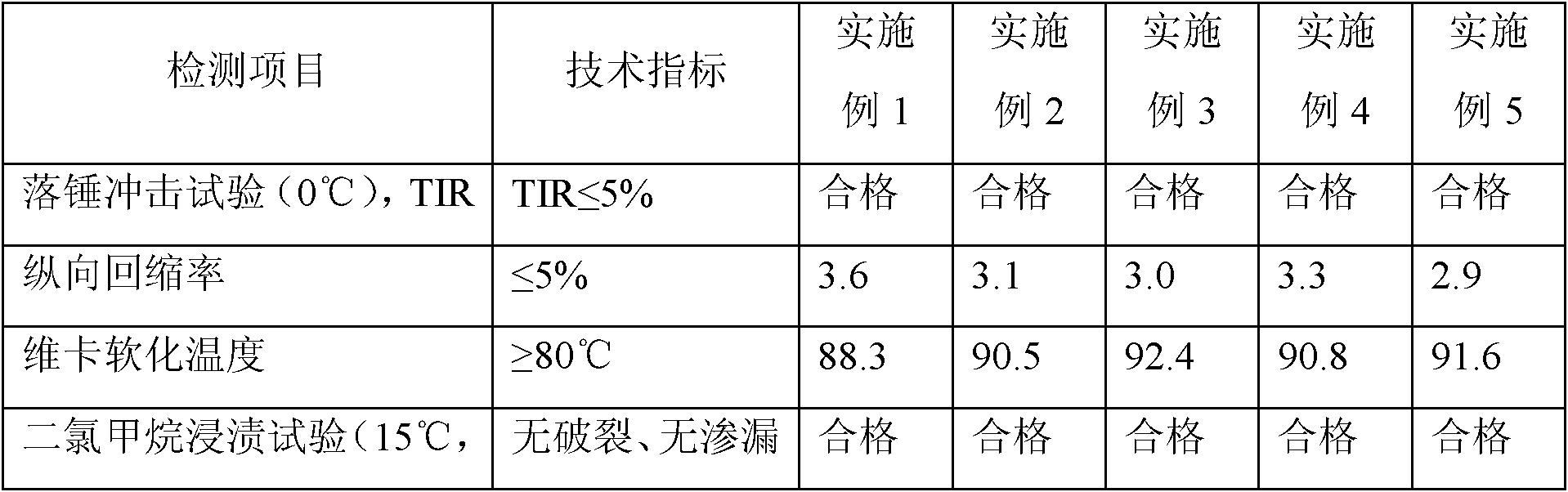

[0032] The preparation method of this PVC pipe is the same as that described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com