Single wire steel cord

A technology of steel cord and single wire, which is applied in the direction of wire material processing, manufacturing rings and tires from wire, etc., can solve the problem of cord torsional arc height dependence, and achieve the effects of improving torsion, increasing elongation at break, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

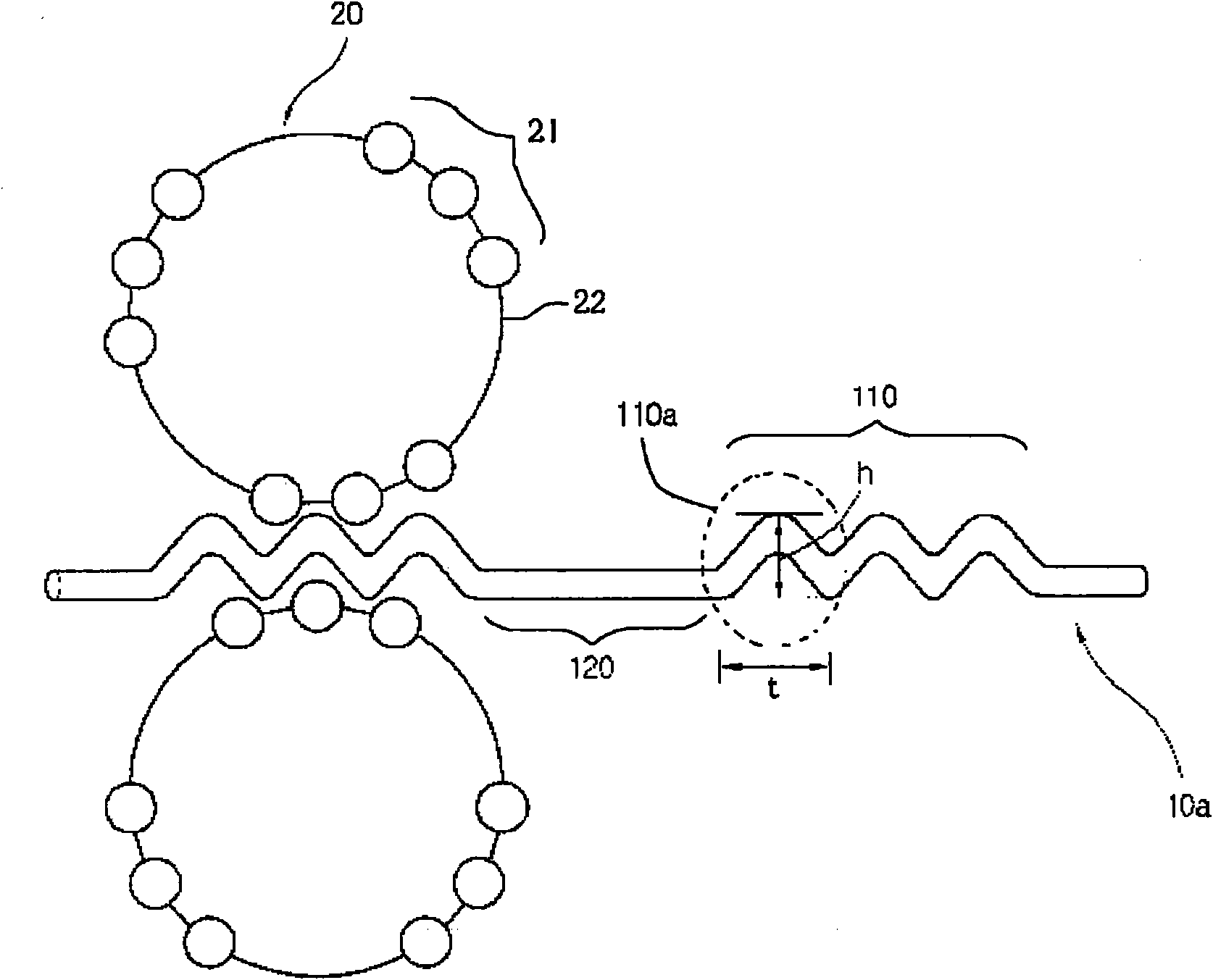

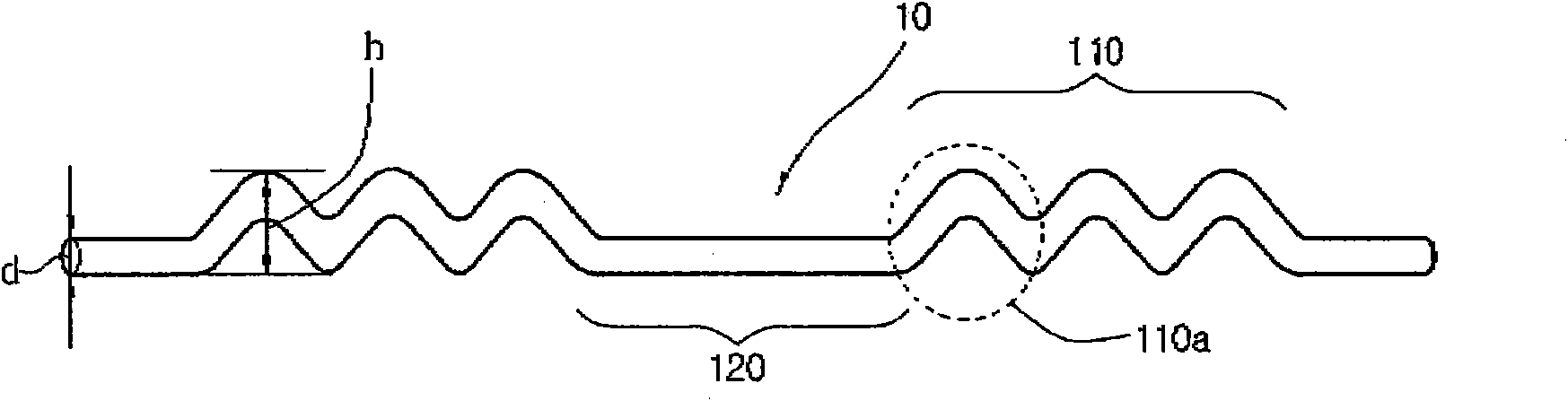

[0038] A wire rod having a carbon content of 0.82% and a diameter of 5.5 mm was first drawn to have a wire diameter of 1.90 mm, then quenched and brass plated. Then, it was subjected to a second drawing treatment so as to have a diameter of 0.40 mm to prepare a monofilament. Next, corrugations were formed on partial regions of the monofilament using a helical device so that each corrugated region included four corrugations and had a length of 10 mm, and each non-corrugated region had a length of 10 mm. Steel cords were produced using straightening R / O, and their physical properties were evaluated. The results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com