Chlorinated polrvinyl chloride modified material as well as preparation method and application thereof

A technology of chlorinated polyvinyl chloride and modified materials, applied in conductors, electrical components, circuits, etc., can solve the problem that CPVC is not suitable for wire and cable sheathing materials, CPVC brittleness and impact resistance and other mechanical properties improvement, etc. problem, to achieve the effect of superior processability, improved brittleness and impact resistance, heat resistance and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

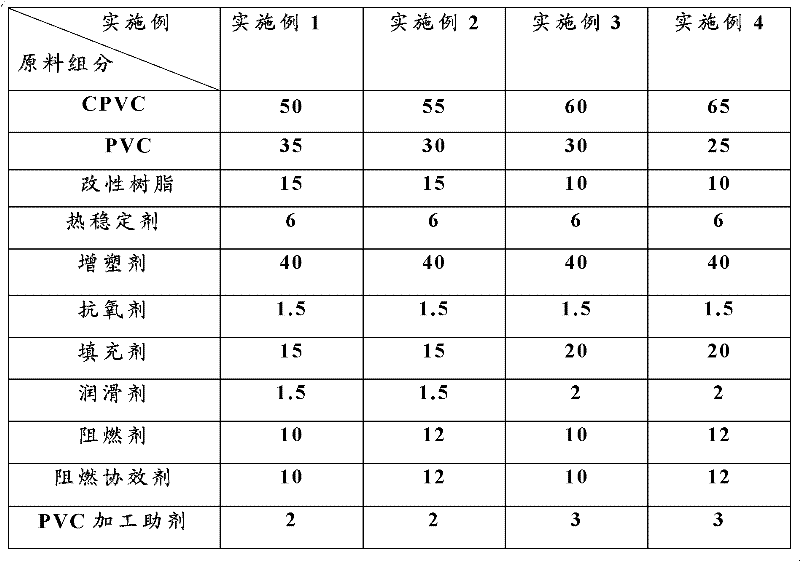

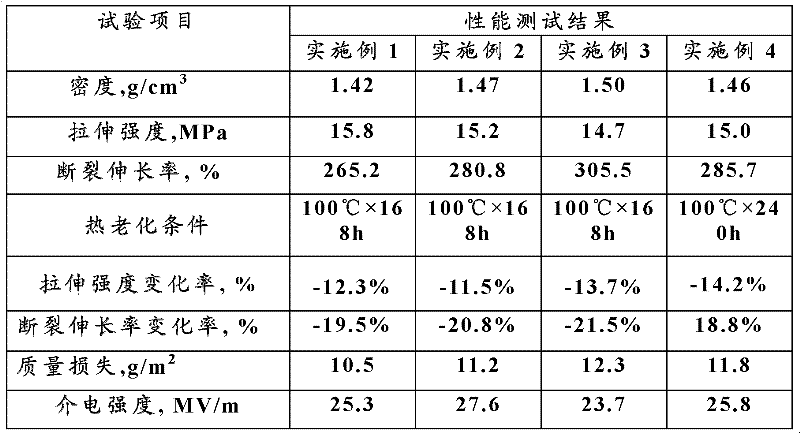

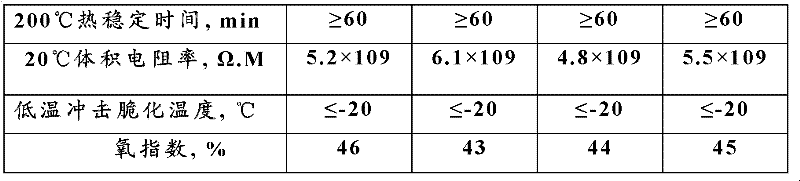

[0021] This embodiment provides a method for preparing a chlorinated polyvinyl chloride modified material, the raw materials used are as follows:

[0022] CPVC: The degree of polymerization is 1000, and the chlorine content is 68%;

[0023] PVC: PVC K: 65;

[0024] Modified resin: chlorinated polyethylene;

[0025] Heat stabilizer: a mixture of calcium-zinc composite stabilizer and organic tin stabilizer in a weight ratio of 3:1;

[0026] Flame retardant: surface-treated antimony trioxide (purchased from Hunan Anhua Huayu Antimony Industry Co., Ltd.);

[0027] Flame retardant synergist: zinc borate;

[0028] Lubricant: polyethylene wax;

[0029] Antioxidant: Tetra[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester and tri[2.4-di-tert-butylphenyl]phosphite Coordination system, the weight ratio of the two is 1:2;

[0030] Plasticizer: a mixture of trimellitic acid phosphate and epoxidized soybean oil, the weight ratio of the two is 4:1;

[0031] ...

Embodiment 2

[0035] This embodiment provides a method for preparing a chlorinated polyvinyl chloride modified material, the raw materials used are as follows:

[0036] CPVC: The degree of polymerization is 1000, and the chlorine content is 63%;

[0037] PVC: PVC K: 65;

[0038] Modified resin: MBS;

[0039] Heat stabilizer: a mixture of calcium-zinc composite stabilizer and organic tin stabilizer in a weight ratio of 2:1;

[0040]Flame retardant: surface-treated antimony trioxide (purchased from Hunan Anhua Huayu Antimony Industry Co., Ltd.);

[0041] Flame retardant synergist: ammonium molybdate;

[0042] Lubricant: polyethylene wax;

[0043] Antioxidant: Tetra[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester and tri[2.4-di-tert-butylphenyl]phosphite Coordination system, the weight ratio of the two is 1:2;

[0044] Plasticizer: a mixture of trimellitic acid phosphate, epoxy soybean oil and DOA, the weight ratio of the three is 3:1:1;

[0045] Filler: act...

Embodiment 3

[0049] This embodiment provides a method for preparing a chlorinated polyvinyl chloride modified material, the raw materials used are as follows:

[0050] CPVC: The degree of polymerization is 1000, and the chlorine content is 68%;

[0051] PVC: PVC K: 65;

[0052] Modified resin: chlorinated polyethylene

[0053] Heat stabilizer: calcium zinc composite stabilizer;

[0054] Flame retardant: surface-treated antimony trioxide (purchased from Hunan Anhua Huayu Antimony Industry Co., Ltd.)

[0055] Flame retardant synergist: a mixture of zinc borate and ammonium molybdate in a weight ratio of 2:1;

[0056] Lubricant: microcrystalline paraffin;

[0057] Antioxidant: Thiobisphenol antioxidant;

[0058] Plasticizer: trioctyl trimellitate;

[0059] Filler: active calcium carbonate;

[0060] PVC processing aid: a mixture of ACR-201 and ACR-401, the weight ratio of the two is 1:1;

[0061] The preparation method is specifically as follows: according to the formula in Table 1, we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com