Corrosion-resistant electric conduction and heat conduction chlorinated polyvinyl chloride resin material and preparation method and application thereof

A chlorinated polyvinyl chloride, electrical and thermal conductivity technology, applied in the field of modified plastics, can solve the problems of low electrical and thermal conductivity, poor chemical resistance, high raw material cost, etc., and achieve good mechanical properties, high production efficiency, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

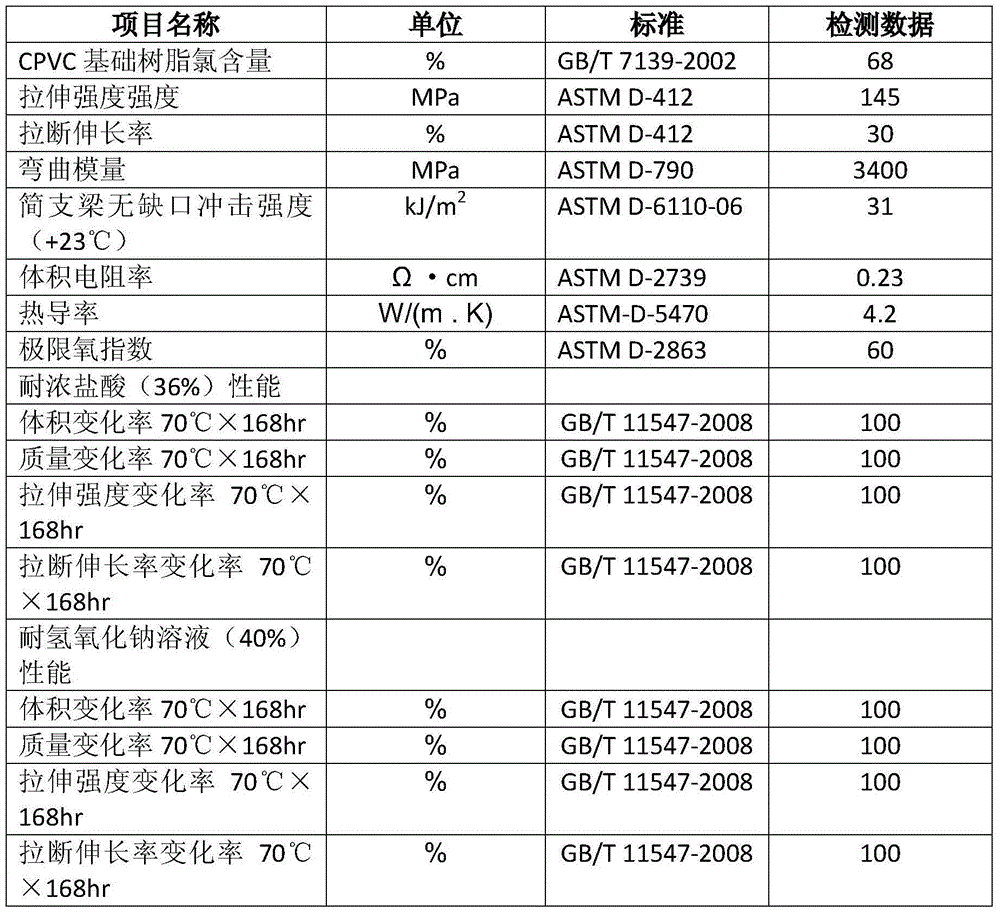

Embodiment 1

[0060] 1. Dissolve 20.3g of nickel nitrate and 17.9g of magnesium nitrate in 100ml of absolute ethanol to prepare a mixed catalyst precursor solution, and prepare a 1:1 mixed solution of 0.7mol / L of nickel nitrate and magnesium nitrate. Apply the prepared precursor solution evenly on the copper substrate and let it dry naturally;

[0061] 2. Put the tin wire under the substrate after being wound, and put it on the deposition table in the cavity of the DC plasma chemical vapor deposition equipment. Close the vacuum chamber and turn on the vacuum pump to evacuate. When the vacuum reaches 0.1 Pa, argon and hydrogen are introduced into the vacuum chamber. The flows of argon and hydrogen are 4L / min and 10L / min respectively, start the DC arc, adjust the arc current to 120A, adjust the exhaust valve and the vacuum chamber regulating valve to stabilize the pressure in the vacuum chamber at 3000Pa, and react for 8min to obtain Ni / MgO catalyst;

[0062] 3. Under the condition of main...

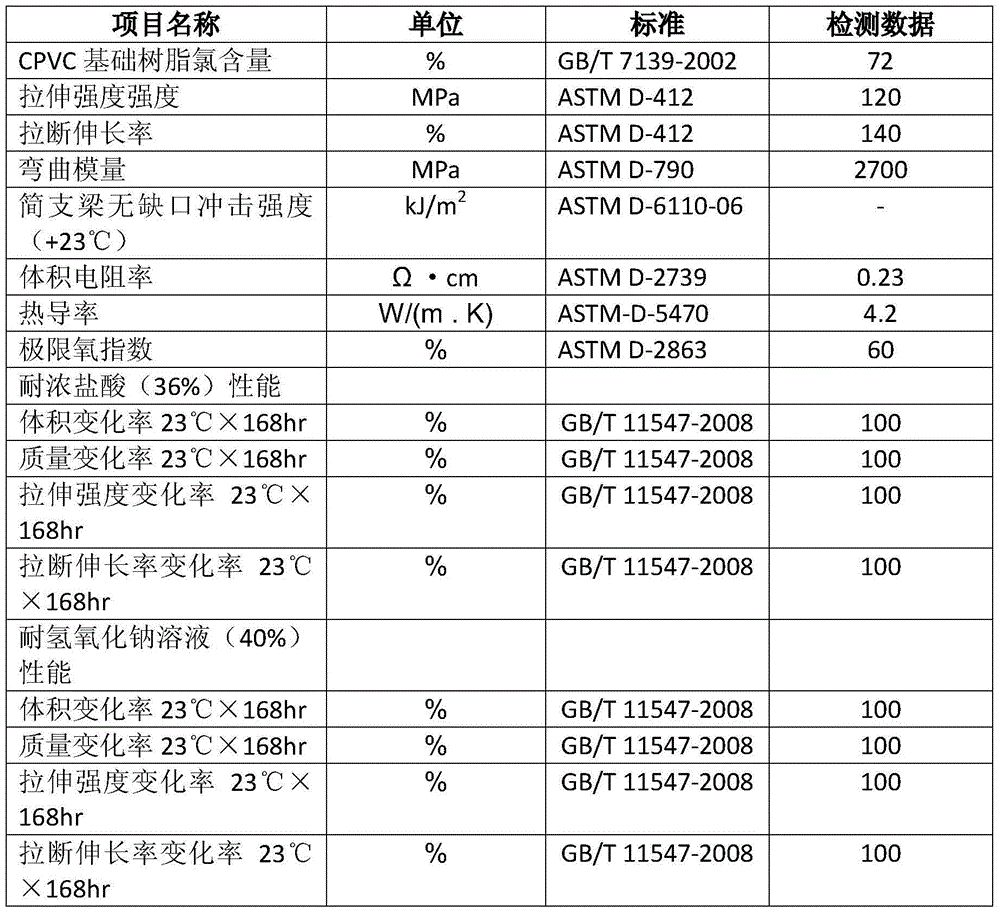

Embodiment 2

[0075] 1. The preparation and surface treatment of modified carbon nanotubes, graphene and aluminum nitride are the same as steps 1 to 6 in Example 1.

[0076] 2. Add 14.5kg of deionized water into a 35L reactor, add 300ml of 1% polyvinyl alcohol dispersant with an alcoholysis degree of 78.5, 250ml of 1% methylcellulose E50, and 2.8ml of 30% Polyvinyl alcohol with an alcoholysis degree of 47, 2ml antifoaming agent methyl silicone, 5.3g ammonium bicarbonate, 2ml ammonia water, 1gEDTA, 1.5g organotin TM181, 5g 1-chloro-1-iodane, stir well and seal Vacuum to -0.09MPa, add 9.5kg ethylene vinyl chloride monomer (VCM) and 6ml50% cumyl peroxyneodecanoate and 5ml50% tert-butyl peroxide neoheptanoate in a closed manner, stir and heat up to 60 ℃ reaction temperature, reactor pressure 0.96MPa, control the reaction temperature difference ± 0.5 ℃ and react for 10hr, when the reaction pressure drops to 0.86MPa, add 6g terminator piperidine alcohol oxide and 4gβ-(3,5-di-tert-butyl -4-Hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com