Chlorinated polyvinyl chloride pipe material and preparation method thereof

A technology of chlorinated polyvinyl chloride and pipe materials, which is applied in pipes, rigid pipes, mechanical equipment, etc., can solve the problems of limiting the development prospects of construction pipes, heat resistance, etc., and achieve the effect of small density, good dispersion, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

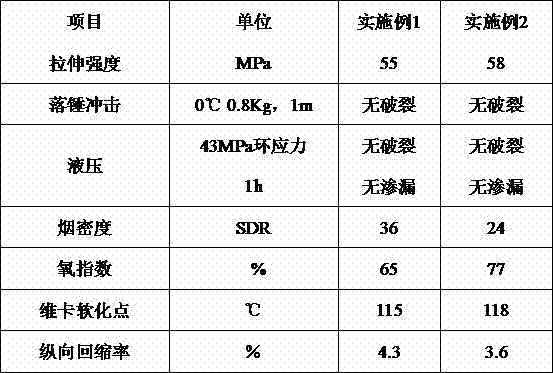

Embodiment 1

[0023] The pipe formula is made of the following components in parts by weight: 100 parts of chlorinated polyvinyl chloride resin, 0.5 parts of organotin stabilizer, 0.6 parts of polyethylene wax, 0.5 parts of oxidized polyethylene, 0.5 parts of metal soap lubricant, ACR 1 part of processing aid, 2 parts of ACR impact modifier, nano-SiO 2 Impact modifier 1 part, TiO 2 1.5 parts of pigment, 1 part of aluminum hydroxide, 2.5 parts of magnesium hydroxide, and 1.5 parts of zinc borate.

Embodiment 2

[0025] The pipe formula is made of the following components in parts by weight: 100 parts of chlorinated polyvinyl chloride resin, 4 parts of calcium zinc stabilizer, 1 part of oxidized polyethylene, 0.4 part of polyethylene wax, 1.5 parts of ACR processing aid, MBS Impact modifier 4 parts, nano-SiO 2 Impact modifier 3 parts, TiO 2 1.5 parts of pigment, 3 parts of ammonium octamolybdate, 1 part of copper oxide.

[0026] 1. Mixing:

[0027] Put each component into the high-low speed mixing unit in proportion to stir, wherein the temperature of the high-speed mixed material is controlled at 105°C, and the temperature of the low-speed mixed material is controlled at 45°C;

[0028] 2. Extrusion molding:

[0029] Taking the extruded CPVC water supply pipe 75×5.6mm (0.6MPa) as an example, put the cold-mixed compound into the conical twin-screw extruder for extrusion, and set the barrel temperature of the conical twin-screw extruder to 185 ℃ 180℃ 175℃ 160℃, the mold temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com