Crosslinked high flame-retardant foamed polyvinyl chloride modified material

A polyvinyl chloride and modified material technology, applied in the direction of plastic/resin/wax insulators, organic insulators, conductors, etc., can solve the problems of high cost and difficult to achieve, to improve high temperature resistance, improve electrical performance, Effect of improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

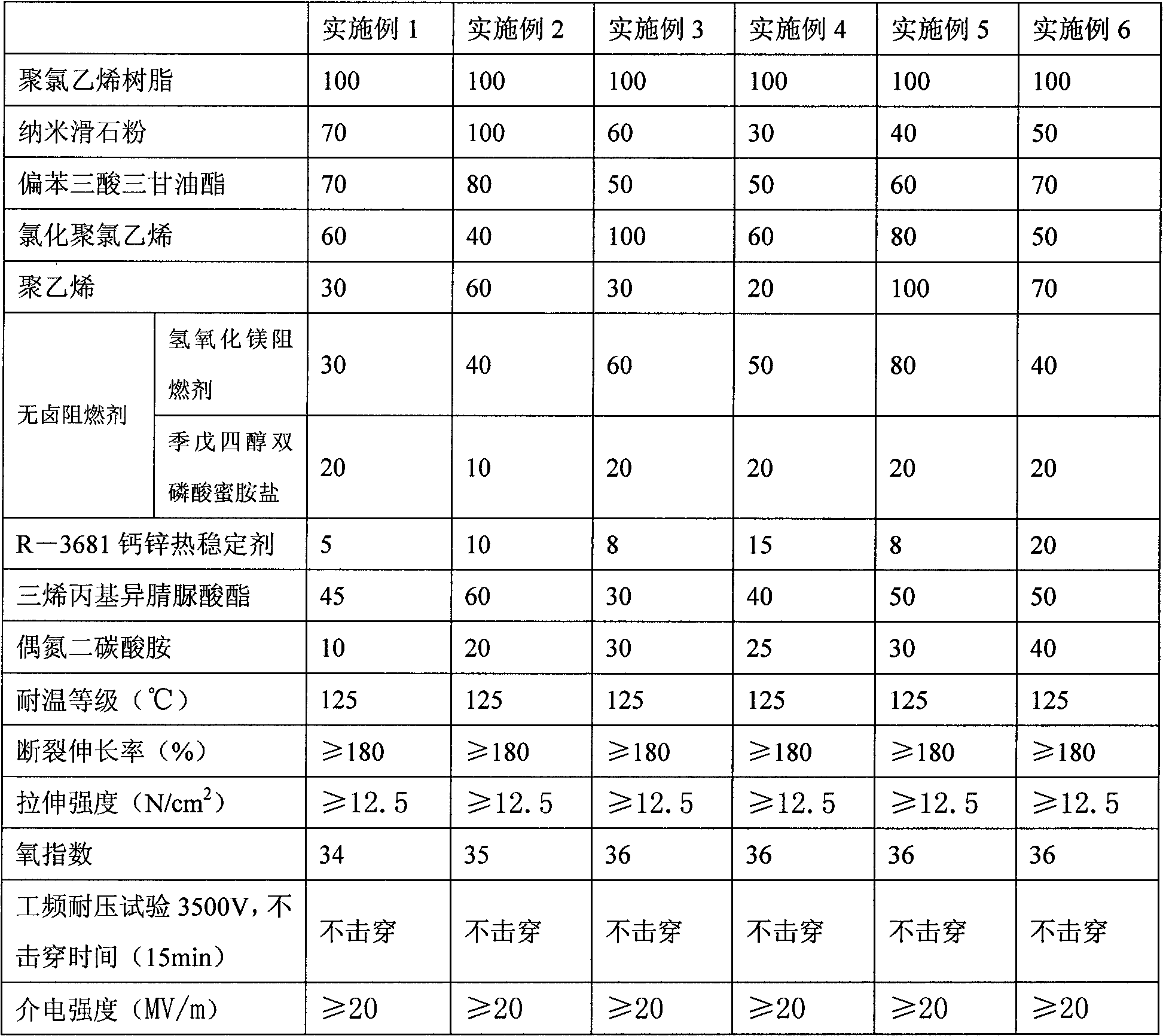

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the embodiments.

[0014] 1. The preparation process of the cross-linked high flame-retardant foamed polyvinyl chloride modified material in the embodiment of the present invention is as follows:

[0015] Prepare raw materials according to the proportion of ingredients, first add polyvinyl chloride resin powder, polyester plasticizer, halogen-free flame retardant, cross-linking agent, calcium and zinc heat stabilizer into the mixer and stir at high speed for about 10 minutes, to 80 ℃ material temperature, Then add chlorinated polyvinyl chloride resin and stir at high speed for about 2 minutes to reach the material temperature of 100 °C. Finally, add talc, polyethylene PE and foaming agent and stir at high speed for about 8 minutes. When the material temperature reaches 100 °C, the material is discharged to the 150-type double A screw extruder performs plastic granulation. The temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com