UPVC pipe material/element and preparation method thereof

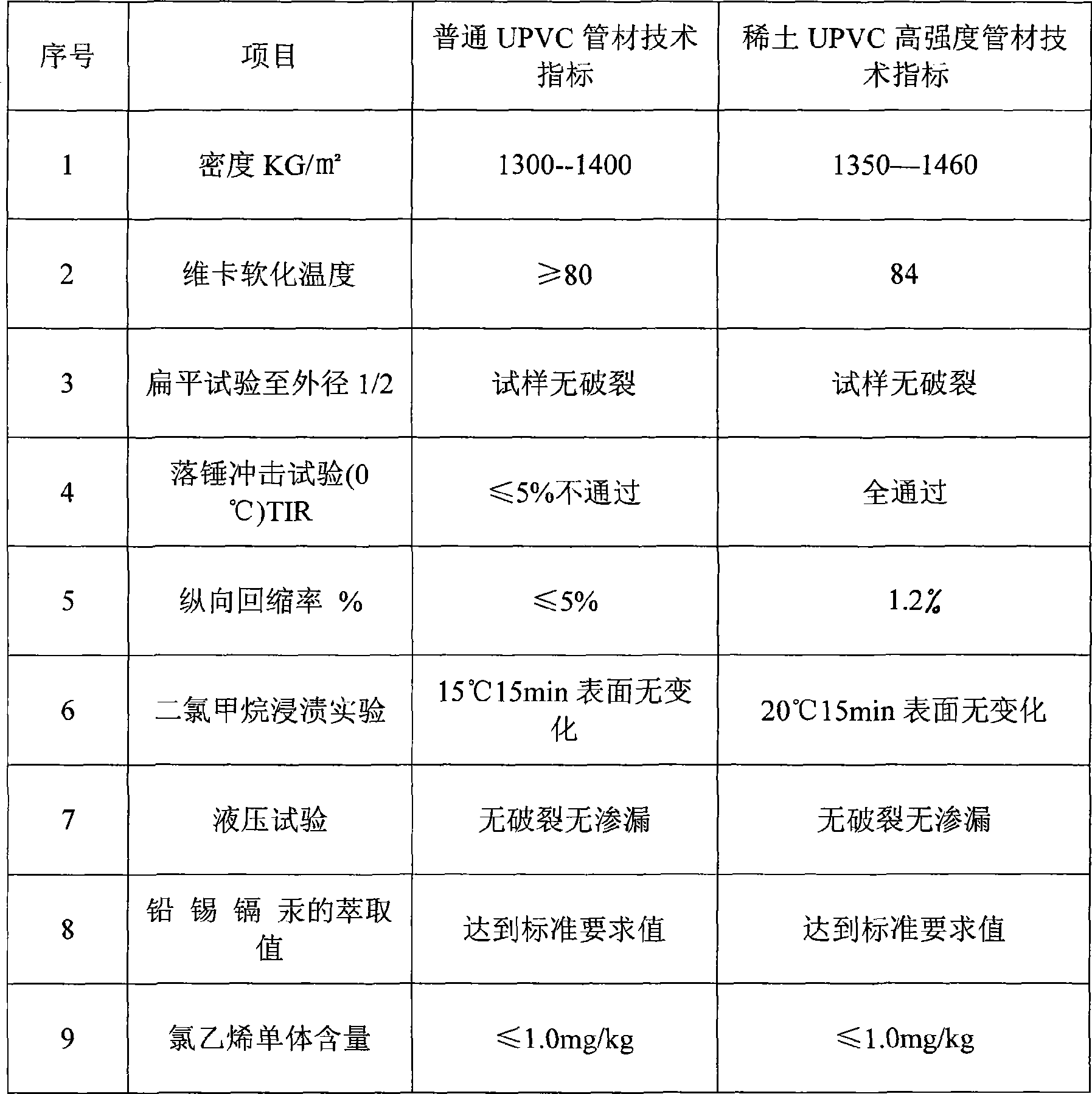

A technology for pipes and polyvinyl chloride resins, applied in the field of plastic processing, can solve the problems of poor mechanical properties of pipes or pipe fittings, unreasonable formulations, poor mechanical properties, etc., and achieves improved mechanical properties, reduced structural defects, and increased heat resistance temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052]UPVC pipes, in parts by weight, contain 50 parts of polyvinyl chloride resin; 0.75 parts of hard lead; 0.85 parts of hard calcium carbonate; 4 parts of chlorinated polyethylene; 2 parts of polyvinyl chloride resin processing modifier; 0.28 parts of paraffin; 0.23 parts of stearic acid; 4.5 parts of light calcium carbonate; 0.15 parts of rare earth composite stabilizer.

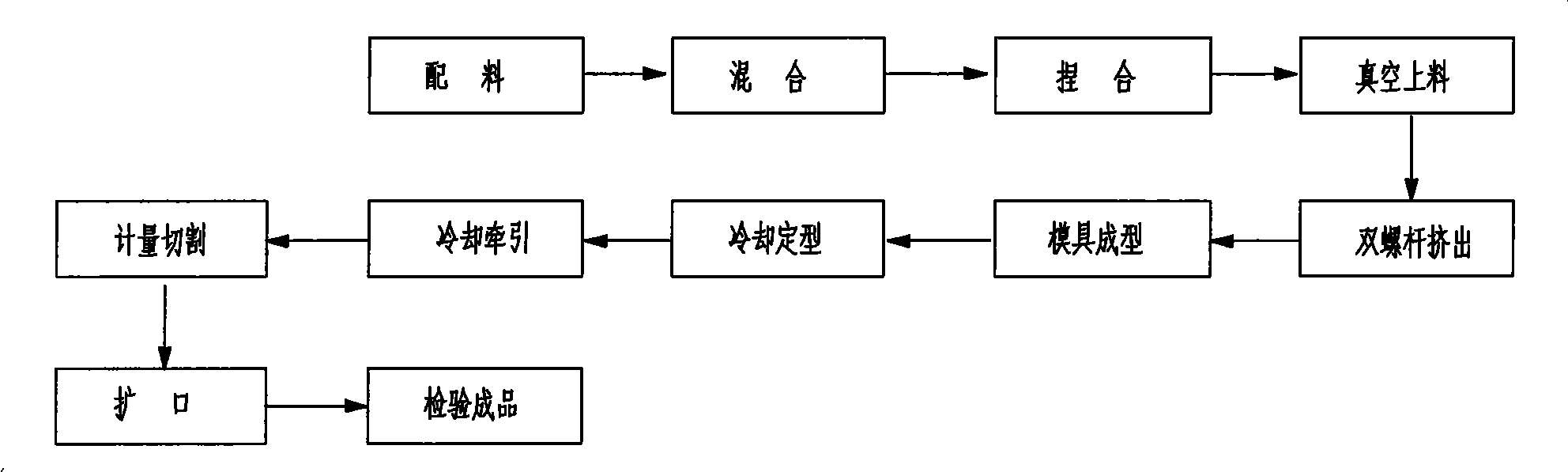

[0053] The preparation method of the pipe is as follows:

[0054] 1) Stir polyvinyl chloride resin, hard lead, hard calcium carbonate, chlorinated polyethylene, polyvinyl chloride resin processing modifier, paraffin, stearic acid, light calcium carbonate and rare earth composite stabilizer, and mix well ;

[0055] 2) Kneading the fully mixed raw materials in step 2 at a temperature of 8°C;

[0056] 3) In a vacuum environment, the material is automatically loaded through the automatic feeding machine;

[0057] 4) Put the above mixture into a twin-screw extruder and extrude it into a mold. The specific ...

Embodiment 2

[0066] UPVC pipe material, by weight, contains 80 parts of polyvinyl chloride resin; 1 part of hard lead; 1.2 parts of hard calcium carbonate; 5 parts of chlorinated polyethylene; 3 parts of polyvinyl chloride resin processing modifier; 0.4 part of paraffin; 0.4 parts of stearic acid; 7 parts of light calcium carbonate; 0.25 parts of rare earth composite stabilizer.

[0067] The preparation method of the pipe is as follows:

[0068] 1) The polyvinyl chloride resin, hard lead, hard calcium carbonate, chlorinated polyethylene, polyvinyl chloride resin processing modifier, paraffin, stearic acid, light calcium carbonate and rare earth composite stabilizer prepared according to the formula Stir well and mix thoroughly;

[0069] 2) Kneading the fully mixed raw materials in step 2 at a temperature of 60°C;

[0070] 3) Loading in a vacuum environment;

[0071] 4) Put the above mixture into a twin-screw extruder and extrude it into a mold. The specific parameters are:

[0072] Die...

Embodiment 3

[0080] The UPVC pipe material contains 100 parts by weight of polyvinyl chloride resin; 1.4 parts of hard lead; 1.7 parts of hard calcium carbonate; 9.4 parts of chlorinated polyethylene; 5 parts of polyvinyl chloride resin processing modifier; 0.6 parts of paraffin; 0.6 parts of stearic acid; 10 parts of light calcium carbonate; 0.5 parts of rare earth composite stabilizer.

[0081] The preparation method of the pipe is as follows:

[0082] 1) raw material processing;

[0083] 2) The polyvinyl chloride resin, hard lead, hard calcium carbonate, chlorinated polyethylene, polyvinyl chloride resin processing modifier, paraffin, stearic acid, light calcium carbonate and rare earth composite stabilizer prepared according to the formula Stir well and mix well;

[0084] 3) kneading the fully mixed raw materials in step 2 at a temperature of 115°C;

[0085] 4) Loading in a vacuum environment;

[0086] 5) Put the above mixture into a twin-screw extruder and extrude it into a mold. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com