Heat-resistant polyvinyl chloride alloy material and preparation method thereof

A technology for polyvinyl chloride and alloy materials, applied in the field of heat-resistant polyvinyl chloride alloy materials and their preparation, can solve the problems of inability to change the processing performance of PVC, inability to coordinate the heat resistance and strength and toughness of PVC materials, and achieve high performance. The effect of improving performance and functionality, increasing added value, and expanding the range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

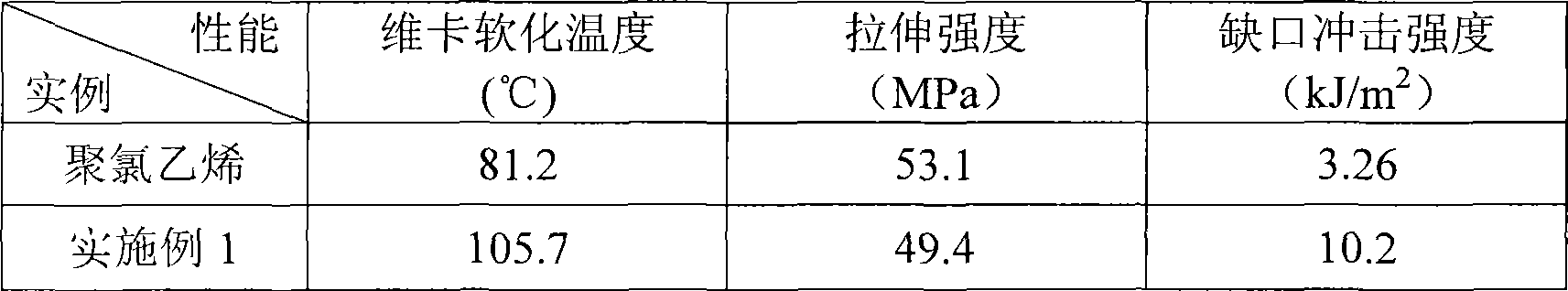

Embodiment 1

[0035]Put 100g of PVC resin, 1.5g of tribasic lead sulfate, 3.5g of calcium stearate and hindered phenol compound into mechanochemical reaction equipment, and react at about 20°C (15-30°C) for about 0.5h to obtain mechanochemical Modified processing aids.

[0036] 100g of PVC resin and 500g of ABS heat-resistant modifier, 4g of composite lead salt (FZ-101), 1.0g of stearic acid, and 1.5g of the above-mentioned mechanochemically modified processing aids were mixed in a high-speed mixer, 110°C Left and right discharge, and then the mixture is melted and blended on a twin-roller plastic mixer with a temperature of about 170°C, and the sheet is discharged after 8 minutes, and the heat-resistant polyvinyl chloride alloy material is prepared. In order to measure the properties of the material, the prepared heat-resistant polyvinyl chloride alloy material was molded into 1mm and 4mm plates on a semi-automatic pressure molding machine at about 185°C, and cut to prepare samples for use...

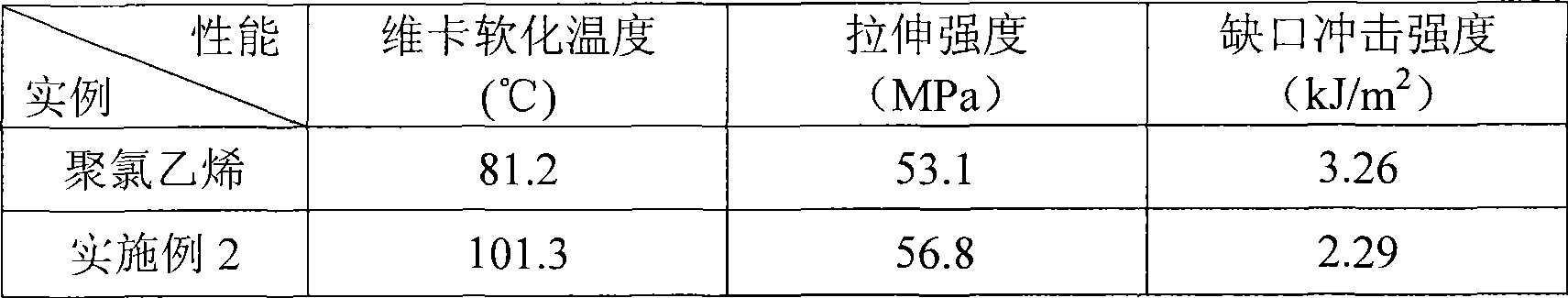

Embodiment 2

[0040] Put 100g of PVC resin, 2.0g of composite lead salt (FZ-101), 5g of calcium stearate and phosphite compound into the mechanochemical reaction equipment, and react at about 15°C (15-30°C) for about 0.5h, Mechanochemically modified processing aids are obtained.

[0041] 80g of heat-resistant modifier (NR-188) and 20g of nanoscale CaCO 3 and 20g of alcohol in a mechanochemical reactor for about 3 hours to obtain an organically modified filler.

[0042] Mix 100g of PVC resin with 120g of the organically modified filler prepared above, 6g of composite lead salt (FZ-101), 1.5g of stearic acid, and 2.0g of the modified processing aid prepared above in a high-speed mixer at about 120°C The material is discharged, and then the mixture is melted and blended on a twin-roller plastic mixer at a temperature of about 170°C, and the sheet is discharged after 8 minutes, and the heat-resistant polyvinyl chloride alloy material is prepared. In order to measure the properties of the mate...

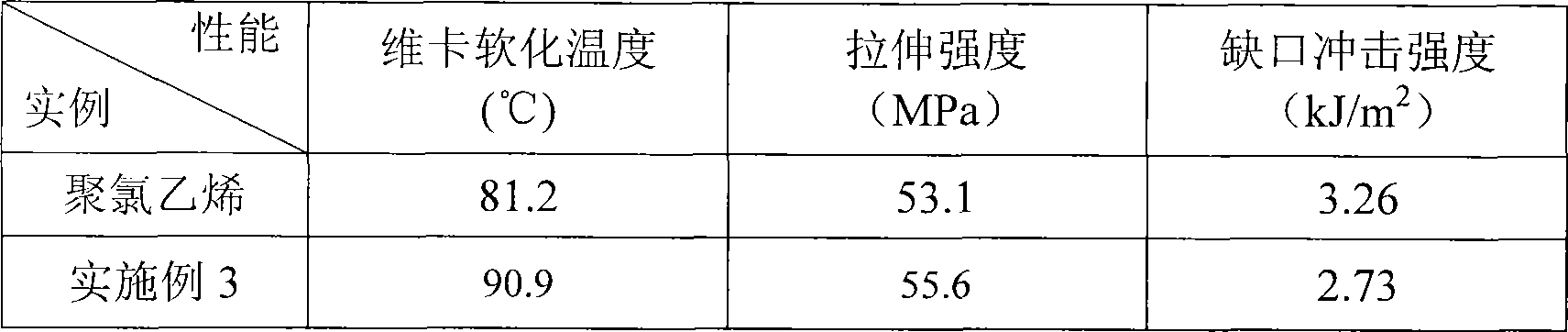

Embodiment 3

[0046] Put 100g of PVC resin, 2.5g of calcium zinc stabilizer (Bear brand 9700), 4.0g of lubricant (ZB-60) and antioxidant (1010) into the mechanochemical reaction equipment, at about 25°C (15~30 °C) for about 0.5 h to obtain a mechanochemically modified processing aid.

[0047] 70g heat-resistant modifier SMA, 20g nano-scale SiO 2 , 10g of PVC and 10g of alcohol were placed in a mechanochemical reactor and reacted for about 3 hours to obtain an organically modified filler.

[0048] Mix 100g of PVC resin with 20g of the organically modified filler prepared above, 4g of calcium zinc stabilizer (Bear brand 9700), 1.0g of calcium stearate, and 1.8g of the processing aid prepared above in a high-speed mixer at about 100°C The material is discharged, and then the mixture is melted and blended on a twin-roller plastic mixer at a temperature of about 170°C, and the sheet is discharged after 8 minutes, and the heat-resistant polyvinyl chloride alloy material is prepared. In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com