Polyurethane sealant with good initial adhesion

A technology of polyurethane sealant and initial tack, applied in the field of materials, can solve problems such as poor bonding strength, slow bonding speed on the surface of non-porous substrates, etc., and achieve excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

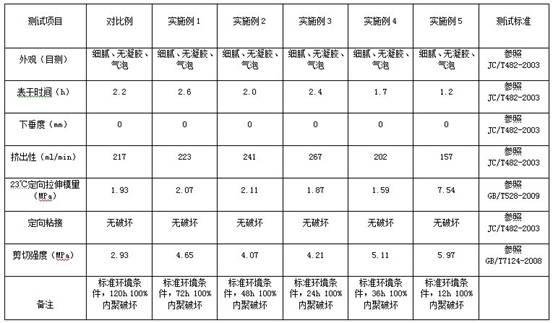

Examples

Embodiment 1

[0056] A polyurethane sealant with good initial tack, comprising raw materials composed of the following mass percentages:

[0057] Polyurethane prepolymer: 45%; dioctyl phthalate: 25%; molecular weight 2000 end mercapto polysulfide rubber: 1.5%; nano fumed silica: 5%; 2000 mesh heavy calcium: 22.15%; UV- 213: 0.02%; Irgastab PUR68: 0.03%; γ-mercaptopropyltrimethoxysilane: 1%; Trimethyl triformate: 0.3%.

[0058] (1) The above-mentioned polyurethane prepolymer is prepared by adding 800 g of polyether polyol with a molecular weight of 2000 bifunctionality and 200 g of polyether polyol with a molecular weight of 5000 trifunctionality in the reaction kettle , Stir and adjust the temperature of the reactor to 100°C. After mixing evenly, remove water for 3.0h under the condition of vacuum degree of 0.096Mpa, and cool down to 65°C. After the temperature is constant, add 232.5g of diphenylmethane-4 , 4'-diisocyanate, and adding 0.001% dibutyltin dilaurate to the total mass of the ab...

Embodiment 2

[0061] A polyurethane sealant with good initial tack, comprising raw materials composed of the following mass percentages:

[0062] Polyurethane prepolymer: 30%; Dioctyl adipate: 30%; Terpene resin: 1.5%; Polyamide thixotropic agent: 1%; 1200 mesh kaolin: 35.45%; UV-213: 0.03%; Irgastab PUR68: 0.02%; γ-glycidyloxypropyltrimethoxysilane: 1.5%; oxazolidine moisture scavengers: 0.5%.

[0063] (1) The above-mentioned polyurethane prepolymer is prepared by adding 500 g of polyether polyol with a molecular weight of 2000 bifunctionality and 500 g of polyether polyol with a molecular weight of 5000 trifunctionality in the reaction kettle , Stir and adjust the temperature of the reactor to 120°C. After mixing evenly, remove water for 2.0 hours under the condition of a vacuum of 0.096Mpa, and cool down to 60°C. After the temperature is constant, add 146.2g of toluene diisocyanate, and add 0.003% of the total mass of the above mixture of stannous octoate was reacted for 2.5 hours to ob...

Embodiment 3

[0066] A polyurethane sealant with good initial tack, comprising raw materials composed of the following mass percentages:

[0067] Polyurethane prepolymer: 35%; phenyl alkylsulfonate: 25%; hydroxyl-terminated nitrile rubber with a molecular weight of 2500: 2.5%; polyoxyalkylene branched silicone thixotropic agent: 1.5%; insulating glass Microbeads: 32.9%; (2,2,6,6-tetramethylpiperidine) sebacate: 0.05%; Irganox 5057: 0.05%; N-β-(aminoethyl)-γ-aminopropyl Trimethoxysilane: 2%; Vinyltrimethoxysilane: 1%.

[0068] (1) The above-mentioned polyurethane prepolymer is prepared by adding 400 g of polyether polyol with a molecular weight of 5000 difunctionality and 600 g of polyether polyol with a molecular weight of 5000 trifunctionality in the reaction kettle , Stir and adjust the temperature of the reactor to 90°C. After mixing evenly, remove water for 3.5 hours under the condition of a vacuum of 0.095Mpa, cool down to 75°C, and add 136.5g of diphenylmethane-4 after the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com