High-temperature resistant flame-retardant environment-friendly PVC (polyvinyl chloride) modified material and preparation method thereof

A modified material and high temperature resistant technology, applied in the field of high temperature resistant flame retardant and environmentally friendly PVC modified materials and their preparation, can solve the problems of human health hazards, poor thermal stability, poor fluidity, etc., and achieve a wide range of applications and electrical insulation properties. Good results with excellent surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

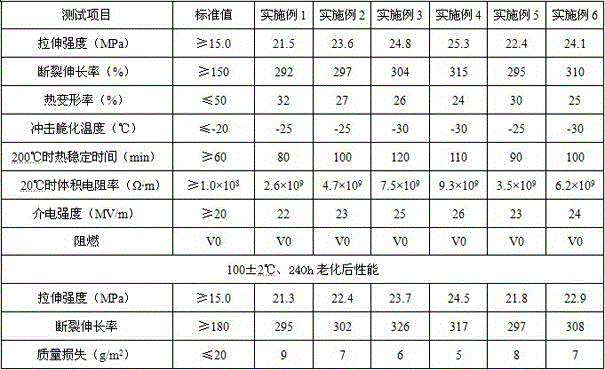

Embodiment 1

[0051] Weigh 80Kg of raw material SG-5 PVC resin, 15Kg of light calcium carbonate, 25Kg of dioctyl terephthalate, 2Kg of antimony trioxide, 3Kg of aluminum hydroxide, 2Kg of calcium-zinc composite stabilizer, and the chlorine content is 25%. chlorinated polyethylene 6Kg, stearic acid 0.5Kg, polyethylene wax 0.5Kg, tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol 0.1Kg mixed; The final raw materials are put into a high-speed blender and stirred at 100°C for 25 minutes; the stirred raw materials are extruded and granulated through a twin-screw extruder, and then cut and air-cooled to obtain high-temperature-resistant, flame-retardant and environmentally friendly PVC Modified material; the screw temperature of the twin-screw extruder is: 138°C for the first stage, 135°C for the second stage, 135°C for the third stage, 132°C for the fourth stage and 130°C for the fifth stage. The mechanical and physical properties of the high-temperature-resistant, flame...

Embodiment 2

[0053] Weigh raw material SG-7 type PVC resin 90Kg, heavy calcium carbonate 25Kg, trioctyl trimellitate 26Kg, epoxy soybean oil 4Kg, antimony trioxide 2.5Kg, aluminum hydroxide 3.5Kg, calcium zinc composite stabilizer 4Kg, 8Kg of chlorinated polyethylene with a chlorine content of 30%, 1.2Kg of polyethylene wax, and 0.3Kg of tris[2.4-di-tert-butylphenyl]phosphite; put the mixed raw materials into a high-speed blender , stirring at 140°C for 15 minutes; extruding and granulating the stirred raw materials through a twin-screw extruder, cutting and air-cooling to obtain a high-temperature-resistant, flame-retardant, and environmentally friendly PVC modified material; the twin-screw extruder The temperature of the extruded screw is: 140°C for the first stage, 140°C for the second stage, 135°C for the third stage, 135°C for the fourth stage and 135°C for the fifth stage. The mechanical and physical properties of the high-temperature-resistant, flame-retardant and environmentally fr...

Embodiment 3

[0055] Weigh raw materials SG-5 type PVC resin 50Kg, SG-7 type PVC resin 50Kg, heavy calcium carbonate 17.5Kg, light calcium carbonate 25Kg, dioctyl terephthalate 24Kg, trioctyl trimellitate 12Kg, 4Kg of epoxy soybean oil, 1.8Kg of antimony trioxide, 5Kg of aluminum hydroxide, 3Kg of calcium zinc composite stabilizer, 2Kg of chlorinated polyethylene with a chlorine content of 35%, 0.6Kg of stearic acid, 0.8Kg of polyethylene wax, β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate n-octadecyl alcohol 0.5Kg mixed; put the mixed raw materials into a high-speed blender, and stir at 120°C for 20min Extrude and granulate the stirred raw material through a twin-screw extruder, and then cut and air-cool to obtain a high-temperature-resistant, flame-retardant, environmentally friendly PVC modified material; the screw temperature of the twin-screw extruder is: a section of 160 ℃, 160°C for the second stage, 155°C for the third stage, 150°C for the fourth stage and 148°C for the fifth stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com