Lightweight noise-reduction modified ABS (Acrylonitrile Butadiene Styrene) material and preparation method thereof

A technology of ABS material and ABS resin, applied in the field of automobile manufacturing, can solve the problem of increasing the weight of the final product, and achieve the effect of improving mechanical properties, good material properties and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

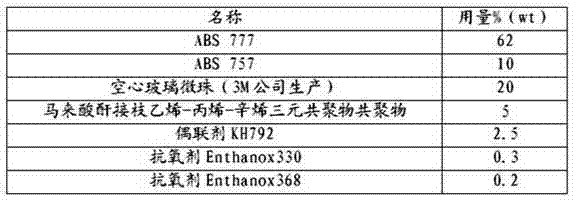

[0041] The formulation of the lightweight noise-reducing modified ABS material in this example is listed in Table 3-1:

[0042] Table 3-1

[0043]

Embodiment 2

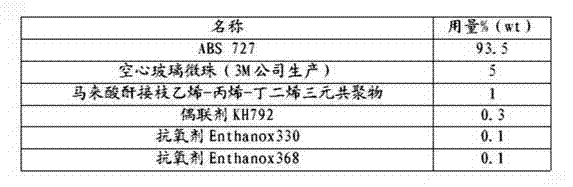

[0045] The formulation of the lightweight noise-reducing modified ABS material in this example is listed in Table 3-2:

[0046] Table 3-2

[0047]

Embodiment 3

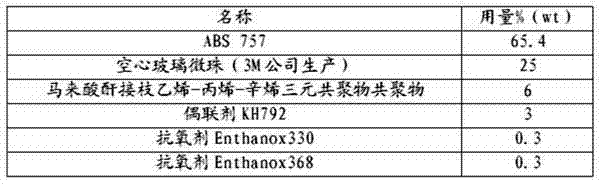

[0049] The formulation of the lightweight noise-reducing modified ABS material in this example is listed in Table 5-3:

[0050] Table 3-3

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com