Antibacterial masterbatch, nano antibacterial super-tough plastic added with antibacterial masterbatch and preparation and application of plastic

An antibacterial masterbatch, plastic technology, applied in the field of polymer materials, can solve the problems of inconvenience in work, study and life, inability to achieve decontamination, sterilization, high toxicity to the human body, etc., achieve drug resistance, color stability, strong toughness, friction Low coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

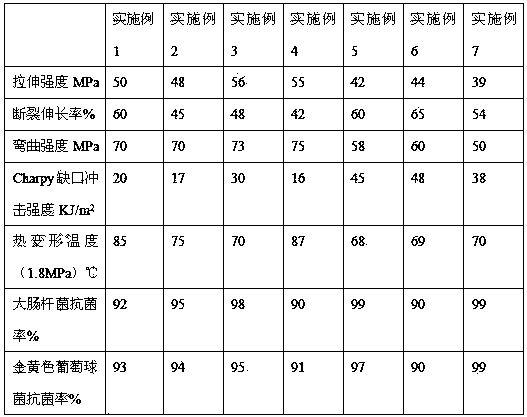

Examples

Embodiment 1

[0031] (1) Preparation of antibacterial masterbatch: firstly, the nano-silica NSG-MQAS grafted with polymer quaternary ammonium salt was treated with silane coupling agent KH550, and the amount of KH550 added was 2% of the mass of inorganic nano-antibacterial agent. Based on the total mass of inorganic nano-antibacterial agent and carrier resin, 25% nano-SiO 2 , 75% PA6 carrier resin and 0.5% EBS dispersant are mixed evenly at high speed, and finally extruded and granulated in a twin-screw extruder to obtain antibacterial masterbatch. The temperature of each section of extrusion is 220°C-250°C.

[0032] (2) Preparation of nano-antibacterial super-tough plastic: Weigh the dried raw materials and processing aids in parts by mass

[0033] PA12 80 parts

[0034] Antibacterial masterbatch 5 parts

[0035] Polyolefin elastomer grafted maleic anhydride (POE-g-MAH) 15 parts

[0036] Antioxidant 1098 0.2 parts

[0037] Antioxidant 168 0.2 parts

Embodiment 2

[0042] (1) Preparation of antibacterial masterbatch: firstly treat nano-silica NSG-MQAS grafted with polymer quaternary ammonium salt with silane coupling agent KH550, and the amount of KH550 added is 2% of the mass of inorganic nano-antibacterial agent. Based on the total mass of the inorganic nano-antibacterial agent and the carrier resin, then 25% nano-SiO 2 , 75% PA6 carrier resin and 0.5% EBS dispersant are mixed evenly at high speed, and finally extruded and granulated in a twin-screw extruder to obtain antibacterial masterbatch. The temperature of each section of extrusion is 220°C-250°C.

[0043] (2) Preparation of nano-antibacterial super-tough plastic: Weigh the dried raw materials and processing aids in parts by mass

[0044] PA6 55 copies

[0045] PA12 30 parts

[0046] Antibacterial masterbatch 5 parts

[0047] Polyolefin elastomer grafted maleic anhydride POE-g-MAH 10 parts

[0048] Antioxidant 1098 0.2 parts

[0049] Antioxidant 168 0.2 parts

[0050] Sil...

Embodiment 3

[0053] (1) Preparation of antibacterial masterbatch: firstly, the nano-silica NSG-MQAS grafted with polymer quaternary ammonium salt was treated with silane coupling agent KH550, and the amount of KH550 added was 2% of the mass of inorganic nano-antibacterial agent. Based on the total mass of the inorganic nano-antibacterial agent and the carrier resin, then 25% nano-SiO 2 , 75% PA6 carrier resin and 0.5% EBS dispersant are mixed evenly at high speed, and finally extruded and granulated in a twin-screw extruder to obtain antibacterial masterbatch. The temperature of each section of extrusion is 220°C-250°C.

[0054] (2) Preparation of nano-antibacterial super-tough plastic: Weigh the dried raw materials and processing aids in parts by mass

[0055] PA6 60 copies

[0056] ABS 30 parts

[0057] Antibacterial masterbatch 5 parts

[0058] 5 parts of styrene-acrylonitrile-maleic anhydride copolymer

[0059] Antioxidant 1098 0.2 parts

[0060] Antioxidant 168 0.2 parts

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com