Composition of air-permeable film with low permeation volume and preparation method thereof

A technology of air permeability and breathable film, which is applied in the field of polyolefin composition, can solve problems such as poor compatibility, unsatisfactory dispersion performance, and uneven air permeability of materials, so as to increase compatibility, improve drawing efficiency and flatness, The effect of enhancing mechanical properties and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

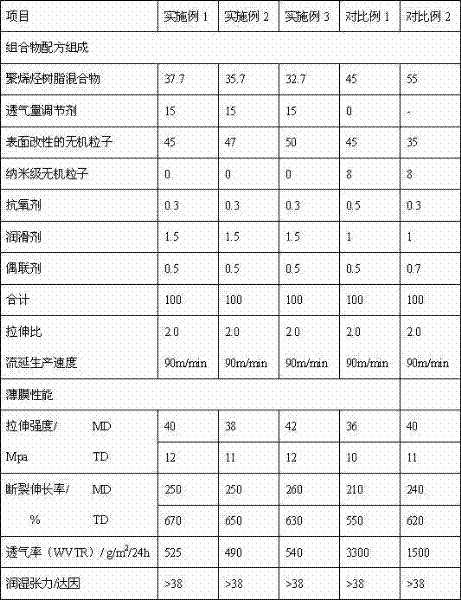

[0029] Weigh certain components and weight percentages as shown in Table 1 by weight percentage, and make the low air permeability gas permeable membrane according to the present invention according to the following steps: 1) Micron-sized inorganic particles are added with coupling agent and mixed at high speed After pretreatment, the micron-sized inorganic filler treated with the coupling agent is added to the feed port of the twin-screw extruder through a metering feeder; 2) polyolefin resin LLDPE (MI: 3.5 density 0.922), ethylene Propylene copolymer, modifier special elastomer EVOH, maleic anhydride graft, lubricant fluoropolymer, zinc stearate, hindered phenolic antioxidant, titanate coupling agent 3) Then feed it into the feed port of the extruder through a metering feeder, melt through twin-screw processing, extrude and granulate to obtain a breathable composition. The extruder is a co-rotating twin-screw extruder with an aspect ratio of 48:1, Do / Di>1.51, a screw speed o...

Embodiment 2

[0031] Weigh certain components and weight percentages as shown in Table 1 by weight percentage, and manufacture the low air flow gas permeable membrane of the present invention according to the following steps: 1) Add coupling agent to micron-sized inorganic particles and pass through a high-speed mixer High-speed mixing, after pretreatment, add the micron-sized inorganic filler treated with the coupling agent to the feed port of the twin-screw extruder through a metering feeder; 2) Mix polyolefin resin medium density polyethylene, ethylene octene copolymer, Modified inorganic particles barium sulfate, titanium dioxide, modifier petroleum resin, EVA, EVOH, lubricant PE wax, calcium stearate, phenolic antioxidant, silane coupling agent are premixed through a premixer, 3) and then It is fed into the feed port of the extruder through a metering feeder, melted through twin-screw processing, extruded and granulated to obtain a breathable composition. The extruder is a co-rotating ...

Embodiment 3

[0033]Weigh certain components and weight percentages as shown in Table 1 by weight percentage, and manufacture the low air flow gas permeable membrane of the present invention according to the following steps: 1) Add coupling agent to micron-sized inorganic particles and pass through a high-speed mixer High-speed mixing, after pretreatment, add the micron-sized inorganic filler treated with the coupling agent to the feed port of the twin-screw extruder through a metering feeder; 2) Add polyolefin resin high-density polyethylene, ethylene and butene copolymer , modified inorganic particles talc powder, calcium carbonate, modifier special polybutene elastomer, EVA, POE, lubricant E wax, oleic acid amide, amine antioxidant, aluminate coupling agent through the premixer Premixing, 3) then feeding into the feed port of the extruder through a metering feeder, melting through twin-screw processing, extruding and granulating to obtain a breathable composition. The extruder is a co-ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com