Preparation method of silica fume polypropylene composite material

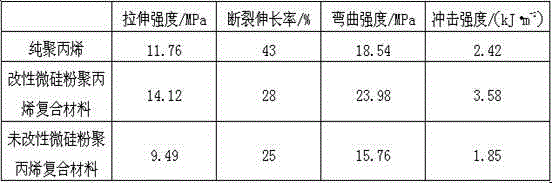

A composite material and micro-silica fume technology, applied in the field of polypropylene material preparation, can solve the problems of poor impact resistance, low dimensional stability, easy embrittlement, etc., and achieve wide application prospects, simple preparation process, and improved impact strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0010] Specific embodiments: the preparation process of the present invention is: 1. micro silica fume pretreatment: get the original silica fume and calcinate it in a box-type resistance furnace, the calcining condition is 600 ℃, and the calcining time is 4h, so as to improve the whiteness and temperature of micro silica fume SiO 2 Content, by m 硅粉 :m 改性剂 :m 分散剂 =100:5:3 mass ratio mixed with absolute ethanol high-speed dispersion beating 5min, slurry mass fraction is 20%, reacted in 40 ℃ water bath for 1h, the dispersant used is sodium dodecylbenzenesulfonate, The surface modifier is a silane coupling agent Si69; 2. Composite material preparation: the polypropylene and the modified micro-silica powder are mixed with a high-speed multi-functional Put the pulverizer into a steel mold placed on a hot press molding machine after high-speed mixing and paving, heat it to a set temperature of 168°C under a pressure of 4 MPa, then keep it warm and pressurized for 30 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com