Polyetheramide toughened epoxy resin

A technology of epoxy resin and polyether amide, which is applied in the field of epoxy resin toughening, can solve the problems of large internal stress, fatigue resistance, poor impact resistance, unfavorable application of epoxy resin, etc., and achieve the effect of improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] use Mw=4100 Mn=1900 Polyetheramide compound curing agent DDM use, for epoxy resin E51 Toughening modification.

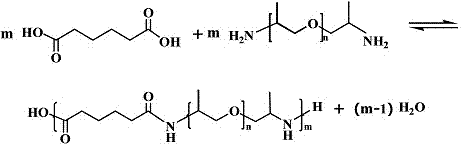

[0018] Polyetheramine-D400 was used to react with adipic acid at 160°C for 8h to prepare polyetheramide with a certain molecular weight. The reaction equation is as follows figure 1 It is characterized by infrared spectroscopy, gel permeation chromatography, end-group titration, viscosity method, and thermogravimetric analysis. The test results show that there are both C-O-C and C=O features in the infrared spectrum of polyetheramide. The absorption peak, and the polyetheramide Mw=4100 Mn=1900 obtained under this condition, the content of terminal amino group is 195mmol / kg, the content of terminal carboxyl group is 192mmol / kg, the relative viscosity is 1.32, and the weight loss temperature of 5% polyetheramide is 310℃, it can have good thermal stability under the temperature conditions of DDM curing epoxy resin E51.

[0019]

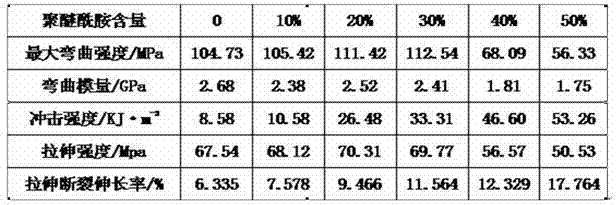

[0020] figur...

example 2

[0025] use Mw=8200 、 Mn=4000 Polyetheramide compound curing agent DDM use, for epoxy resin E51 Toughening modification.

[0026] Polyetheramine-D400 was reacted with adipic acid at 160 °C for 12 h to prepare polyetheramide, and it was characterized by infrared spectroscopy, gel permeation chromatography, end-group titration, viscosity method, and thermogravimetric analysis. The test results show that there are characteristic absorption peaks of C-O-C and C=O in the infrared spectrum of polyetheramide, and the polyetheramide prepared under this condition has Mw=8200, Mn=4000, and the content of terminal amino groups is 126mmol / kg. The carboxyl group content is 132 mmol / kg, the relative viscosity is 1.43, and the weight loss temperature of 5% polyetheramide is 321 ℃, which can have good thermal stability under the temperature conditions of DDM curing epoxy resin E51.

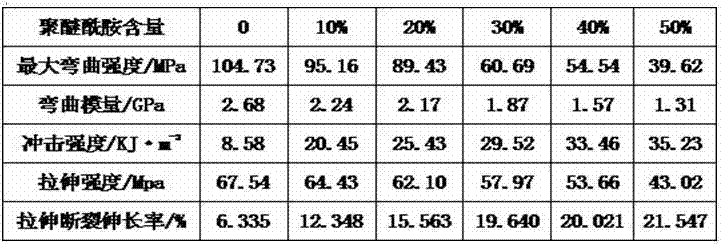

[0027] The polyetheramide prepared by reacting at 160°C for 12h was used as a toughening agent,...

example 3

[0031] use Mw=30400 、 Mn=17300 Polyetheramide compound curing agent DDM use, for epoxy resin E51 Toughening modification.

[0032]Polyetheramine-D400 was reacted with adipic acid at 160°C for 48 hours to prepare polyetheramide, and it was characterized by infrared spectroscopy, gel permeation chromatography, end group titration, viscosity method, and thermogravimetric analysis. The test results show that there are characteristic absorption peaks of C-O-C and C=O in the infrared spectrum of polyetheramide at the same time, and the polyetheramide prepared under this condition has Mw=30400, Mn=17300, the content of terminal amino group is 28mmol / kg, and the content of terminal amino group is 28mmol / kg. The carboxyl content is 30mmol / kg, the relative viscosity is 1.57, and the weight loss temperature of 5% polyetheramide is 347°C. It can have good thermal stability under the temperature conditions of DDM curing epoxy resin E51.

[0033] The polyether amide prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com