Fiber laser device and cutting method for cutting sapphire glass

A technology of sapphire glass and fiber laser, applied in glass manufacturing equipment, laser welding equipment, welding equipment, etc., can solve the problems of high processing cost of sapphire glass, and achieve the effects of easy absorption, faster speed and high electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

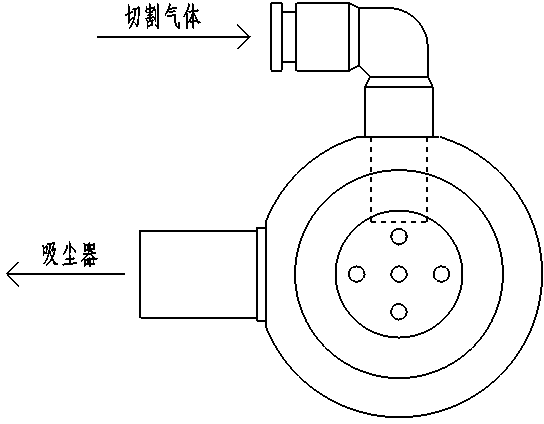

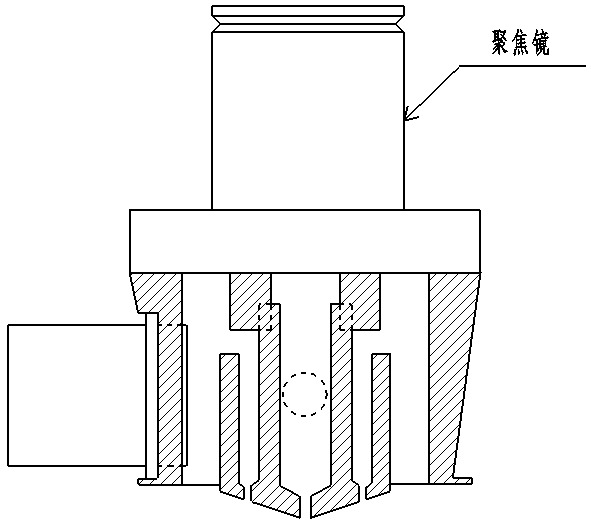

[0023] A method for fiber laser equipment cutting sapphire glass, comprising the following steps:

[0024] (1) Place the polished sapphire glass coated with diionized water, light blocking agent and tension reducing agent on the jig, and adjust the height of the cutting head according to the thickness of the sapphire glass;

[0025] (2) The pressure of debugging and cutting nitrogen is 0.8MPa;

[0026] (3) The focus height of the debugging equipment is 10000step, the speed is 2mm / s, the pulse width is 40us, and the power is 30W;

[0027] (4) Focus the laser beam with a wavelength range of 1065um, single-mode, and continuous pulses at high magnification, so that the diameter of the beam is concentrated to 0.015mm, and it is vertically incident on the surface of the sapphire glass sample to be processed;

[0028] (5) Move the processed sapphire glass so that the surface of the sapphire glass is first ablated to form a "V" groove with an overall thickness of 1 / 8 and then cut thr...

Embodiment 2

[0032] A method for fiber laser equipment cutting sapphire glass, comprising the following steps:

[0033] (1) Place the unpolished sapphire glass coated with single-ion water plus light blocking agent and tension reducing agent on the jig, and adjust the height of the cutting head according to the thickness of the sapphire glass;

[0034] (2) The pressure of the debugging cutting gas is 1.0MPa;

[0035] (3) The focus height of the debugging equipment is 10000-15000step, the speed is 3mm / s, the pulse width is 50us, and the power is 50W;

[0036] (4) Focus the single-mode, continuous-pulse laser beam with a wavelength range of 1070um at high magnification, so that the diameter of the beam is concentrated to 0.02mm, and the laser beam is vertically incident on the surface of the sapphire glass sample to be processed;

[0037] (5) Move the processed sapphire glass to make the sapphire glass penetrate and cut at one time.

[0038]

Embodiment 3

[0040] A method for fiber laser equipment cutting sapphire glass, comprising the following steps:

[0041] (1) Place the polished sapphire glass coated with diionized water, light blocking agent and tension reducing agent on the jig, and adjust the height of the cutting head according to the thickness of the sapphire glass;

[0042] (2) The pressure of the debugging cutting gas is 1.2MPa;

[0043] (3) The focus height of the debugging equipment is 15000step, the speed is 4mm / s, the pulse width is 60us, and the power is 80W;

[0044] (4) Focus the single-mode, continuous-pulse laser beam with a wavelength range of 1078um at high magnification, so that the diameter of the beam is concentrated to 0.03mm, and it is perpendicularly incident on the surface of the sapphire glass sample to be processed;

[0045] (5) Move the processed sapphire glass so that the surface of the sapphire glass is first ablated to form a "V" groove of 1 / 4 of its overall thickness and then penetrated and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Speed | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com