Nano-composite material containing organic sepiolite and its preparation method

A technology of nanocomposite material and organic sepiolite, which is applied in the field of nanocomposite material containing organic sepiolite and its preparation, can solve the problems that have not been reported, and achieve the effects of simple preparation operation, improved bending strength and improved impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

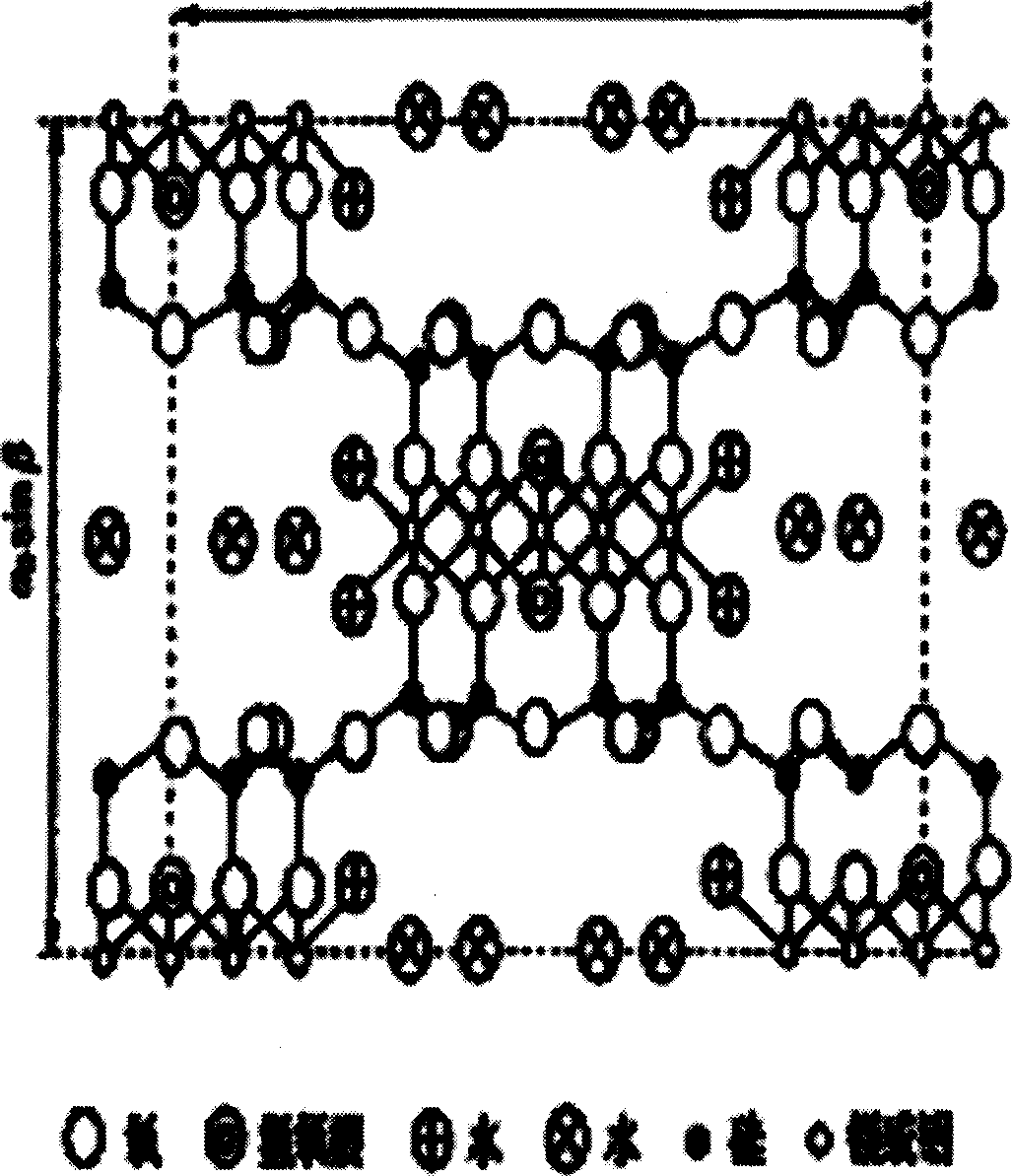

Image

Examples

example 1

[0027] Example 1: Prepare organic sepiolite first

[0028] a) crushing the coarse sepiolite ore to 100 mesh, and adopting wind separation to remove coarse sand;

[0029] b) Take the above-mentioned ore powder and form a concentration of 10% ore slurry, soak it with 1mol / L hydrochloric acid solution to dissolve the carbonate mixed between the sepiolite, wash and filter, dry for later use, and ensure that the content of the sepiolite reaches more than 90 percent;

[0030] c) test the cation exchange capacity of sepiolite;

[0031] d) According to the cation exchange capacity, add dodecyltrimethylammonium chloride in equivalent, use water as the dispersant, and the concentration of the organic exchanger is 10%, so as to promote the cation exchange reaction between the sepiolite particles and the dispersant;

[0032] e) Treat at 65°C for 3 hours, filter, wash, dry, and pulverize to 800 mesh.

[0033] The second adopts the melting intercalation polymer method, and the preparatio...

example 2

[0038] Example 2: Prepare organic sepiolite first

[0039] The first two steps are equivalent to the above preparation process. After testing the organic degree of sepiolite, that is, the cation exchange capacity, add an organic exchanger according to the equivalent of cation exchange capacity: octadecyltrimethylammonium chloride, using water as a dispersant , the concentration of the organic exchanger is 14%, treated at 65°C for 3.5 hours, filtered, washed, dried, and crushed to 800-1250 mesh.

[0040] The second adopts the melting intercalation polymer method, and the preparation steps are as follows:

[0041] Add 5 grams of organic sepiolite to 100 grams of epoxy resin TDE-85, heat up to 50°C, disperse with a mixer for 5-10 minutes, and then stir in a boiling water bath for 1 hour.

[0042] The dispersed mixture was placed in a vacuum drying oven at 80° C. for vacuum defoaming.

[0043] Cool the organic sepiolite / epoxy resin mixture after degassing to room temperature, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com