Polyphenylene sulfide composite material with high impact and high CTI and preparation method and application thereof

A technology of polyphenylene sulfide and composite materials, applied in the field of modified plastics, which can solve the problems of low impact strength, high cost, and high cost of PPS composite materials, so as to facilitate market promotion, facilitate industrial production, and improve impact strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

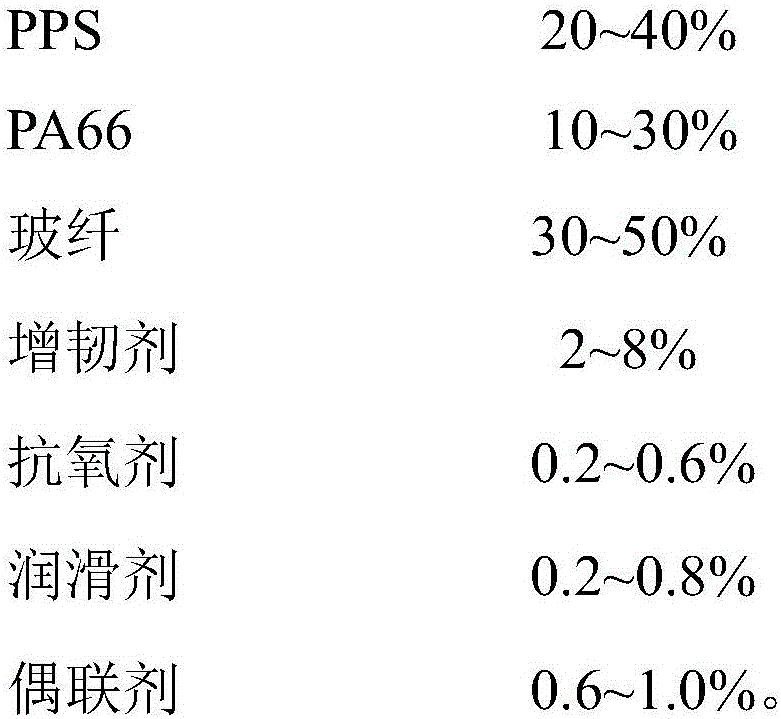

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation method of high impact resistance high CTIPPS composite material, comprises the following steps:

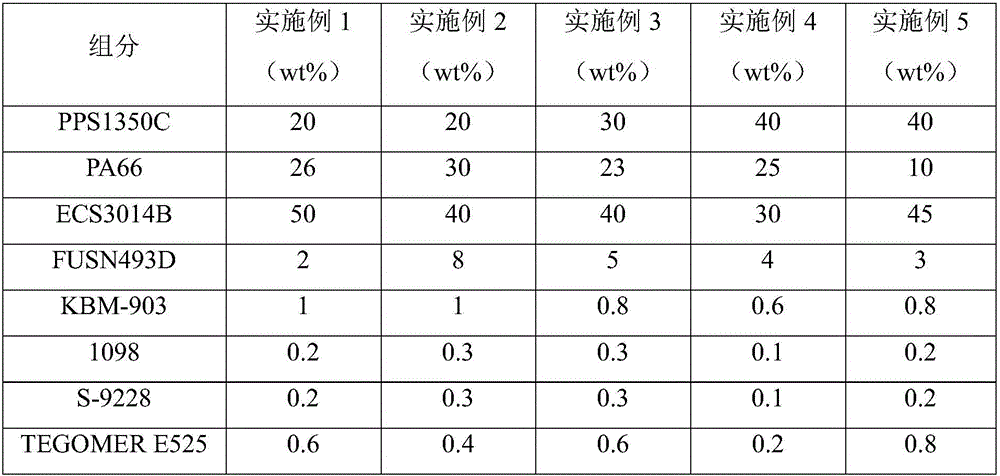

[0043] (1) take raw materials by the amount of PPS, PA66, toughening agent, coupling agent, antioxidant and lubricant in table 1;

[0044] (2) Mix PPS and coupling agent at 120°C for 10 minutes, cool to 60°C, add PA66, toughening agent, antioxidant and lubricant and mix for 5 minutes, then add to the main feeding hopper of the extruder, and feed on the side The glass fiber is added into the hopper, extruded and granulated by a twin-screw extruder.

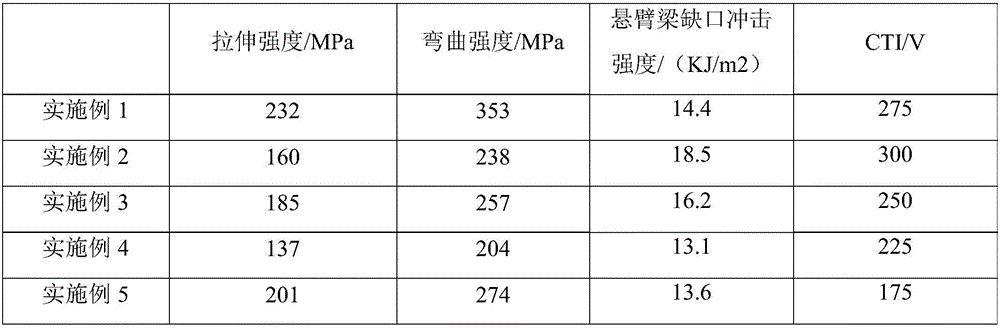

[0045] The rotational speed of the twin-screw extruder is 400r / min, and the temperature is 260-300°C. The properties of the obtained high impact and high CTIPPS composites are shown in Table 2.

Embodiment 2

[0047] A kind of preparation method of high impact resistance high CTIPPS composite material, comprises the following steps:

[0048] (1) take raw materials by the amount of PPS, PA66, toughening agent, coupling agent, antioxidant and lubricant in table 1;

[0049] (2) Mix PPS and coupling agent at 130°C for 9 minutes, cool to 70°C, add PA66, toughener, antioxidant and lubricant and mix for 4 minutes, then add to the main feeding hopper of the extruder, and feed on the side The glass fiber is added into the hopper, extruded and granulated by a twin-screw extruder.

[0050] The rotational speed of the twin-screw extruder is 300r / min, and the temperature is 260-300°C. The properties of the obtained high impact and high CTIPPS composites are shown in Table 2.

Embodiment 3

[0052] A kind of preparation method of high impact resistance high CTIPPS composite material, comprises the following steps:

[0053] (1) take raw materials by the amount of PPS, PA66, toughening agent, coupling agent, antioxidant and lubricant in table 1;

[0054] 2) Mix PPS and coupling agent at 140°C for 8 minutes, cool to 80°C, add PA66, toughener, antioxidant and lubricant and mix for 3 minutes, then add to the main feeding hopper of the extruder, and put it in the side feeding hopper Add glass fiber, extrude and granulate through twin-screw extruder.

[0055] The rotational speed of the twin-screw extruder is 500r / min, and the temperature is 260-300°C. The properties of the obtained high impact and high CTIPPS composites are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com