Fluorine-containing coating material for outdoor protection of 5G communication base station and preparation method thereof

A communication base station, fluorine-containing coating technology, used in anti-corrosion coatings, coatings, polyamide coatings, etc., can solve problems such as inability to meet, and achieve extended service life, excellent corrosion resistance, softness and flexibility, The effect of improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

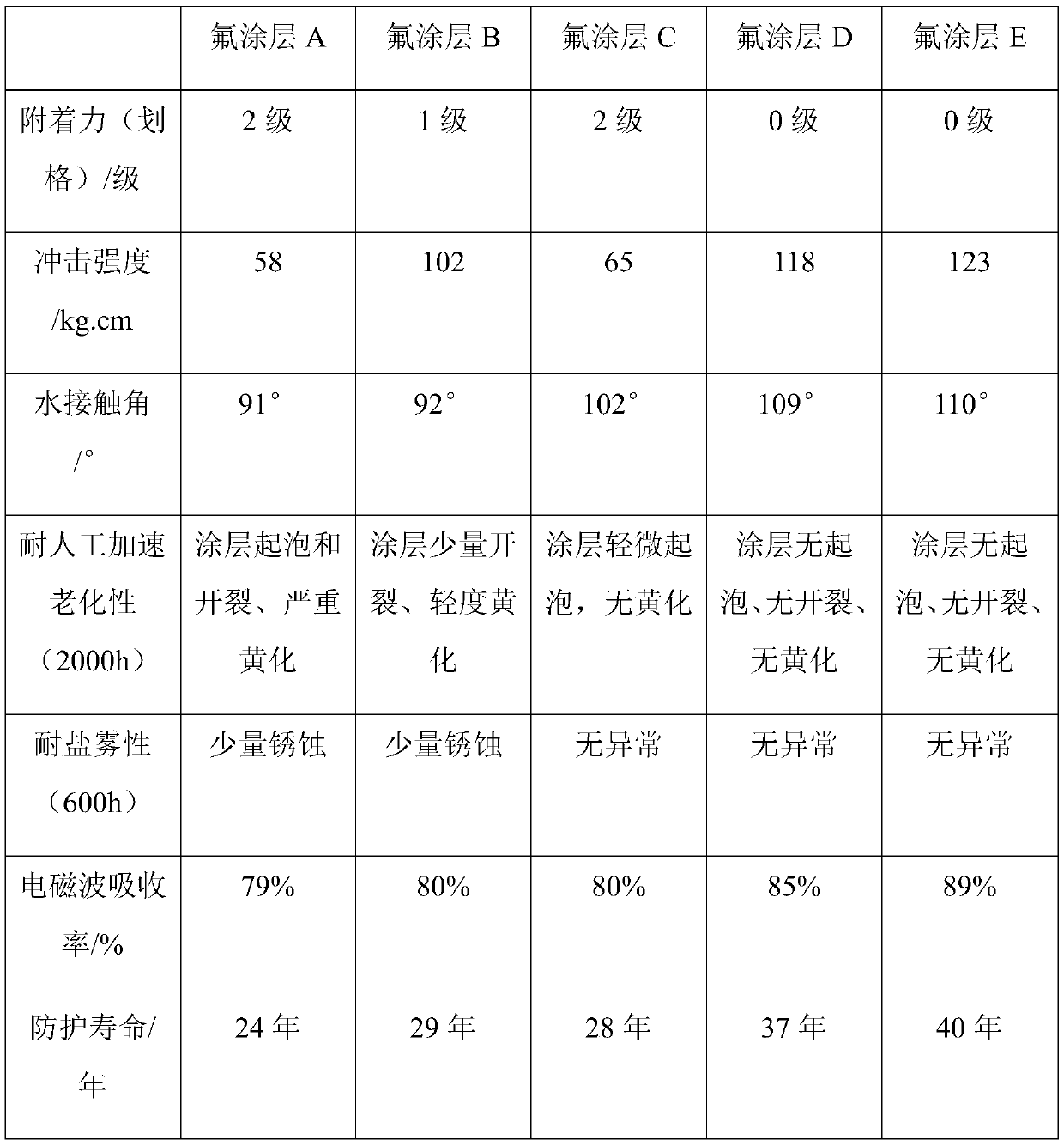

Examples

Embodiment 1

[0031] This embodiment provides a fluorine-containing coating material for outdoor protection of 5G communication base stations. The fluorine-containing coating material is composed of a functional material layer, and the functional material layer includes: 50 parts of fluoropolymer by weight components (polyvinylidene fluoride), 35 parts of wave-absorbing nanoparticles, 10 parts of pigment additives, 70 parts of oily solvent (orthosilicate), 50 parts of aqueous solvent (pure water), 3 parts of emulsifier (polyethylene glycol ), 4 parts of ring-opening catalyst (triethylamine).

[0032] The wave-absorbing nanoparticles include carbon-coated iron nanoparticles with an average particle size of 10 nm, carbon-coated nickel nanoparticles, and carbon nanofoam micropowder in a mass ratio of 1:1:2. Carbon-coated iron nanoparticles, carbon-coated nickel nanoparticles, and carbon nano-foam powders all have good wave-absorbing characteristics, and carbon nano-foam powders have the charac...

Embodiment 2

[0038] This embodiment provides a fluorine-containing coating material for outdoor protection of 5G communication base stations. The fluorine-containing coating material is composed of a base material layer-a functional material layer, and the base material layer includes: 50 parts by weight Epoxy resin, 15 parts of nanofiber dispersion liquid, 30 parts of acetone; said nanofiber dispersion liquid comprises: 41% fluorine-containing polyurethane electrospun fiber, 15% nylon electrospun fiber, and the balance is methanol. The use of electrospun fibers has the advantages of large specific surface area, high porosity, and good fiber uniformity, and the electrospun fibers have excellent interfacial effects, which makes the base material layer have more active sites, which is conducive to the integration between the matrix and functional materials. form a good connection. Among them, the fluorine-containing polyurethane electrospun fiber has the functions of super-hydrophobicity and...

Embodiment 3

[0045] This embodiment provides a fluorine-containing coating material for outdoor protection of 5G communication base stations, the fluorine-containing coating material is composed of a functional material layer-curing material layer, and the functional material layer includes: 53 parts by weight Fluoropolymer (polychlorotrifluoroethylene), 38 parts of wave-absorbing nanoparticles, 11 parts of pigment additives, 74 parts of oily solvent (orthosilicate), 53 parts of aqueous solvent (pure water), 4 parts of emulsifier (polyethylene glycol), 5 parts of ring-opening catalysts (N,N-diethylethanolamine); the absorbing nanoparticles include carbon-coated iron nanoparticles, carbon-coated nickel nanoparticles, and carbon-coated nanoparticles with an average particle diameter of 12nm. The nano foam powder is composed according to the mass ratio of 1:1:2. The pigment additives include: 0.8% acrylic acid leveling agent, 0.8% GPES type defoamer, 0.8% dispersant AYD, 0.8% 2-hydroxybenzoph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com