Wrapping method of nickel-cobalt-aluminum ternary positive electrode material and application

A positive electrode material, nickel-cobalt-aluminum technology, applied in the field of lithium-ion battery positive electrode material preparation, can solve serious problems such as poor surface adhesion of modified materials, particle agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

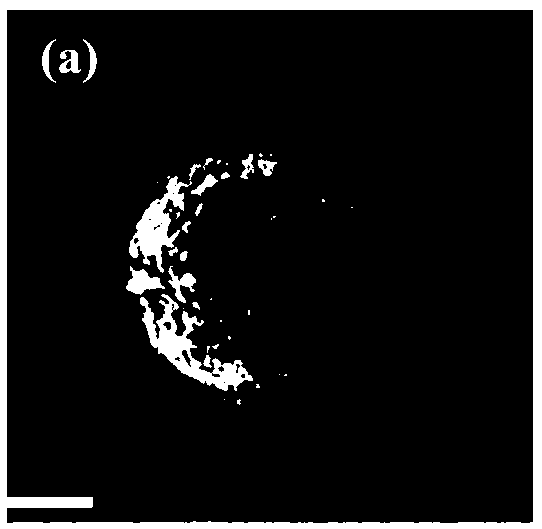

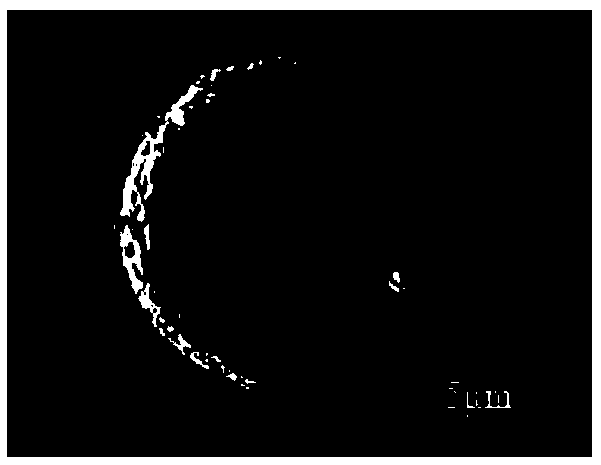

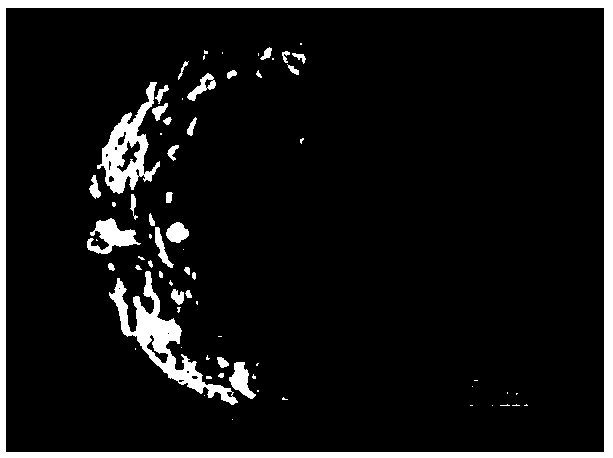

Image

Examples

Embodiment 1

[0074] Embodiment 1: (freeze-dried coating material)

[0075] Step 1: Preparation of Precursor

[0076] NiSO 4 ·6H 2 O. CoSO 4 ·7H 2 O and Al 2 (SO 4 ) 3 18H 2 O is the raw material, and it is calculated according to the ratio n of each element substance in the target product Ni :n Co :n Al =80:15:5 Accurately weigh and prepare 2mol L -1 Sulfate mixed solution, in the form of 4mol·L -1 NaOH is the precipitating agent, 1mol L -1 NH 3 ·H 2 O is a complexing agent. Before the reaction starts, use 100mL deionized water as the bottom solution and perform magnetic stirring, drop the salt solution into the beaker at a certain speed, and the flow rate of the lye (mixed solution of sodium hydroxide and ammonia water) changes with the change of pH Control, salt solution and lye form a precipitate in the beaker, the precipitate is washed and dried to obtain the precursor Ni 0.8 co 0.15 Al 0.05 (OH) 2 .

[0077] Step 2: Nickel-cobalt-aluminum ternary cathode material ...

Embodiment 2

[0082] Embodiment 2: (freeze-dried coating material, 1wt%TiO 2 coating amount)

[0083] Step 1: Preparation of Precursor

[0084] NiSO 4 ·6H 2 O. CoSO 4 ·7H 2 O and Al 2 (SO 4 ) 3 18H 2 O is the raw material, and it is calculated according to the ratio n of each element substance in the target product Ni :n Co :n Al =85:10:5 Accurately weigh and prepare 3mol L -1 Sulfate mixed solution, in the form of 6mol·L -1 NaOH is the precipitating agent, 3mol L -1 NH 3 ·H 2 O is a complexing agent. Before the reaction starts, use 100mL ethanol as the base liquid and carry out magnetic stirring, drop the salt solution into the beaker at a certain speed, and the flow rate of the lye (the mixed solution of sodium hydroxide and ammonia water) is regulated with the change of pH, The salt solution and lye form a precipitate in the beaker, and the precipitate is washed and dried to obtain the precursor Ni 0.8 co 0.15 Al 0.05 (OH) 2 .

[0085] Step 2: Nickel-cobalt-aluminum...

Embodiment 3

[0090] Embodiment 3: (freeze-dried coating material, 5wt%TiO 2 coating amount)

[0091] Step 1: Preparation of Precursor

[0092] With Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·7H 2 O, Al(NO 3 ) 3 18H 2 O is the raw material, and it is calculated according to the ratio n of each element substance in the target product Ni :n Co :n Al =75:20:5 Accurately weigh and prepare 1mol L -1 Nitrate mixed solution, in the form of 2mol·L -1 NaOH is the precipitating agent, 1mol L -1 NH 3 ·H 2 O is a complexing agent. Before the reaction starts, use 100mL deionized water as the bottom solution and perform magnetic stirring, drop the salt solution into the beaker at a certain speed, and the flow rate of the lye (mixed solution of sodium hydroxide and ammonia water) changes with the change of pH Control, salt solution and lye form a precipitate in the beaker, the precipitate is washed and dried to obtain the precursor Ni 0.8 co 0.15 Al 0.05 (OH) 2 .

[0093] Step 2: Nickel-coba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com