Patents

Literature

49results about How to "High sound absorption coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

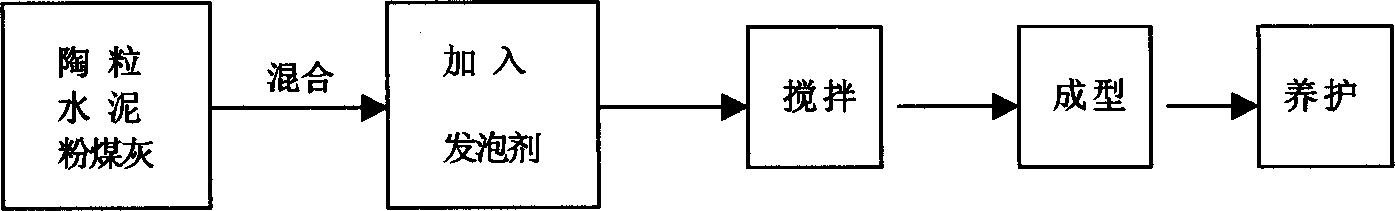

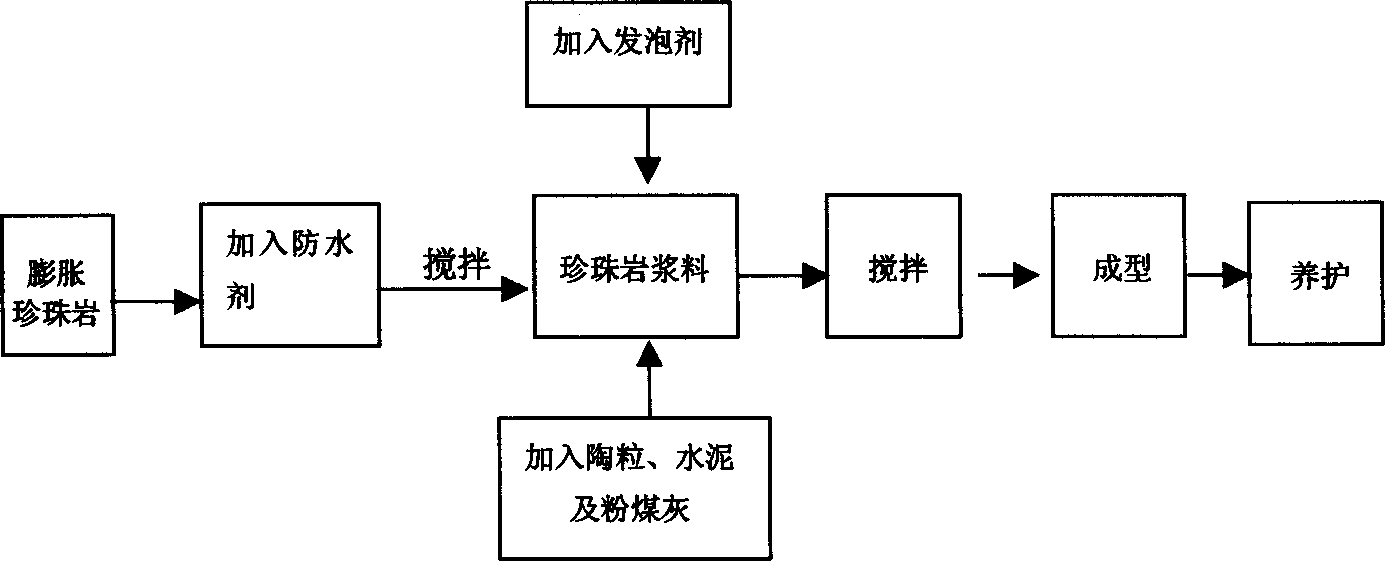

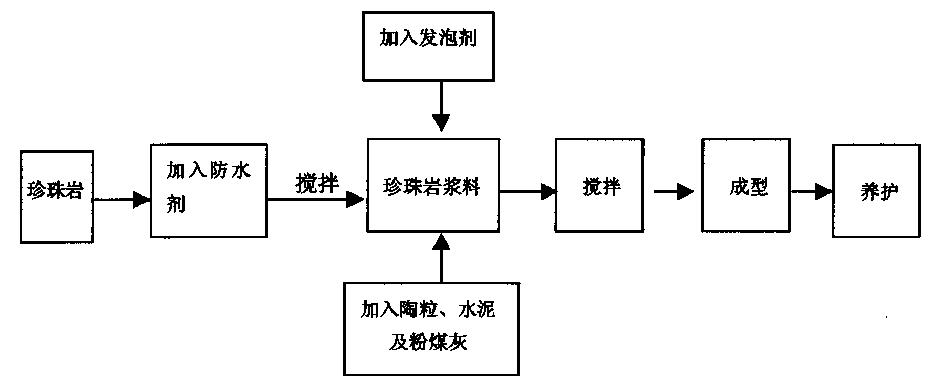

Sound-absorbing material for subway and its preparing process

InactiveCN1346814AFireproofWaterproofSolid waste managementSound proofingFoaming agentExpanded clay aggregate

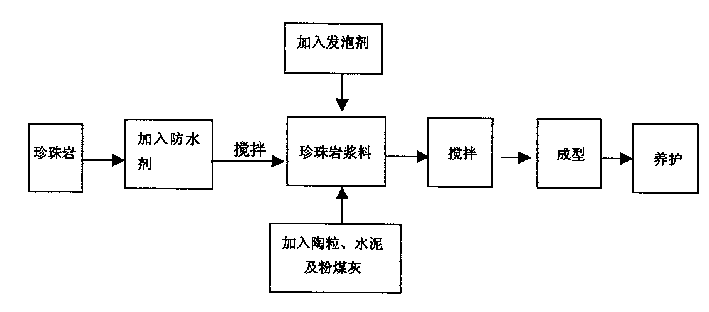

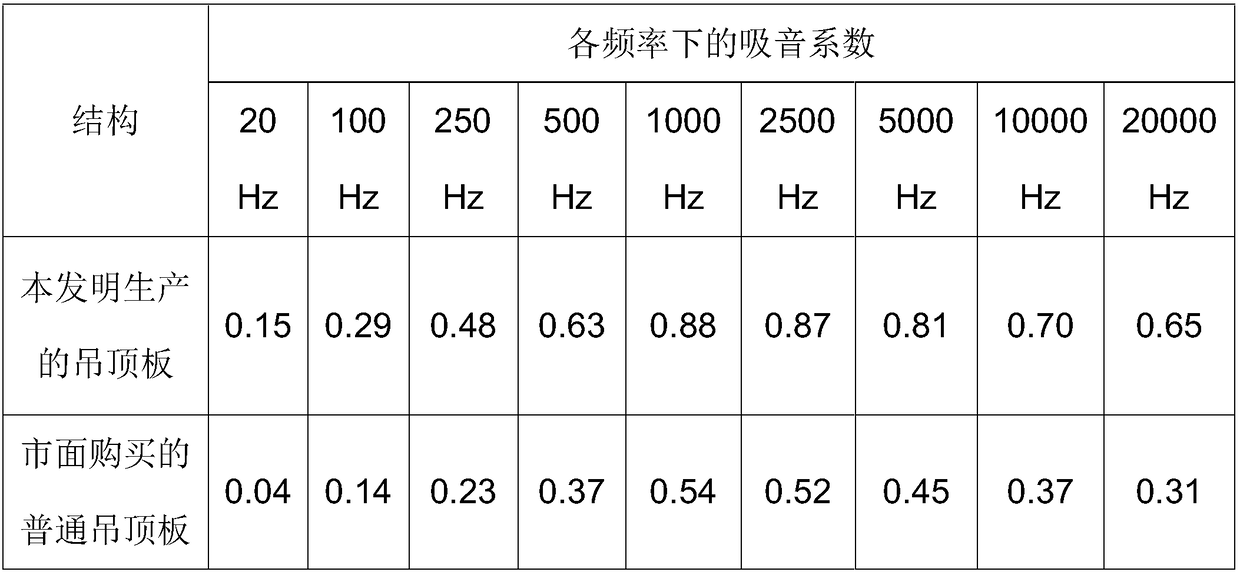

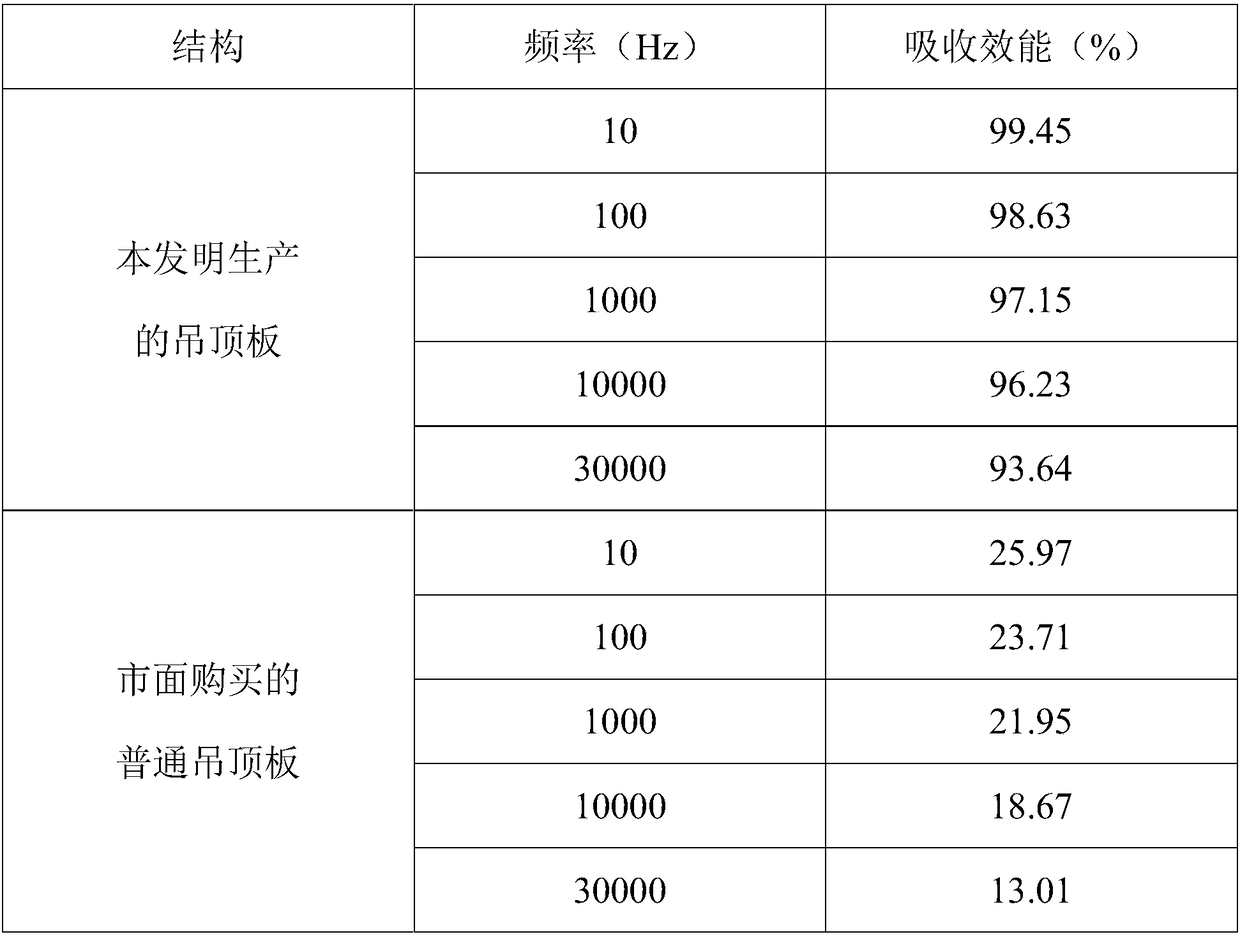

A sound-absorbing material for subway is prepared from haydite (40-70%), cement (20-48%) flyash (0-10%) and foaming agent (1-2%) through diluting foaming agent with water, mixing the others, adding the deluted foaming agent to the mixture and shaping. Its advantages are broad audio band, high sound absorptivity, low volume weight, high strength, resisting fire and water, no toxicity, and low cost.

Owner:曾令可

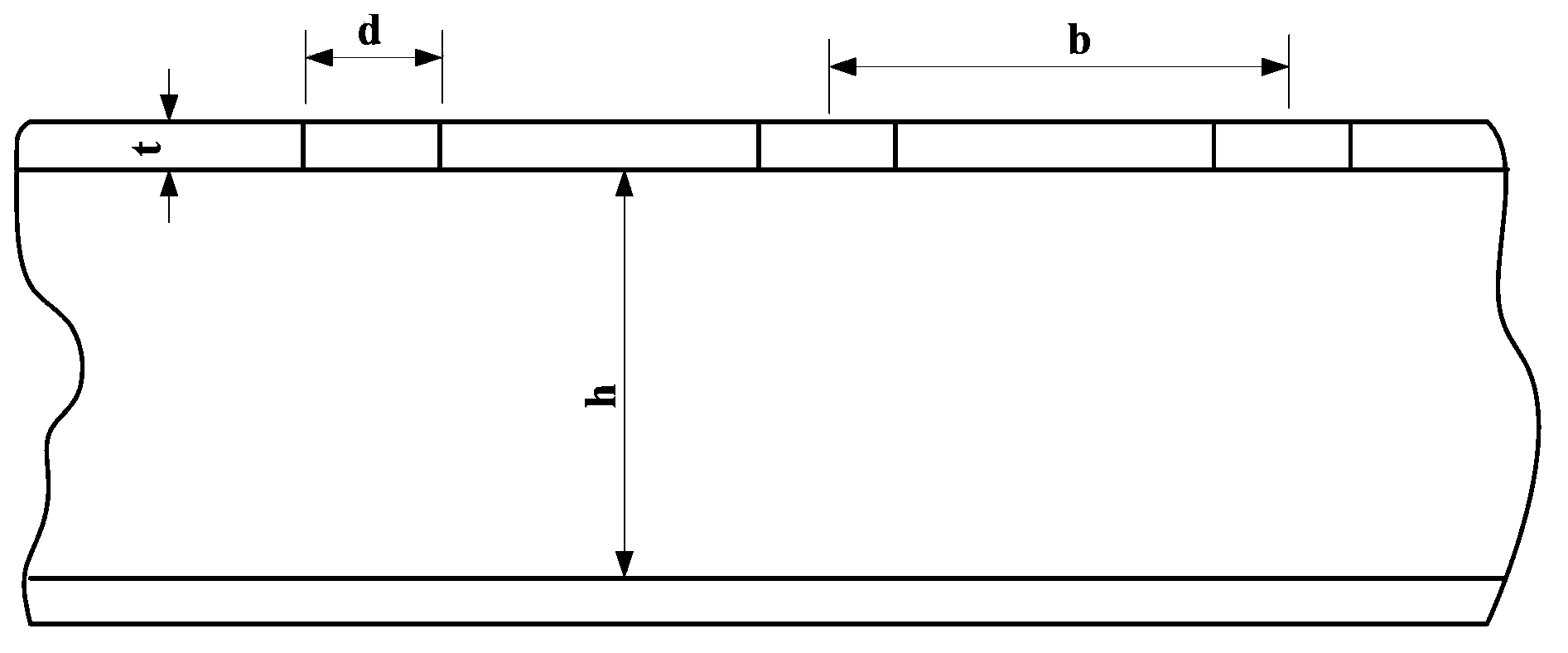

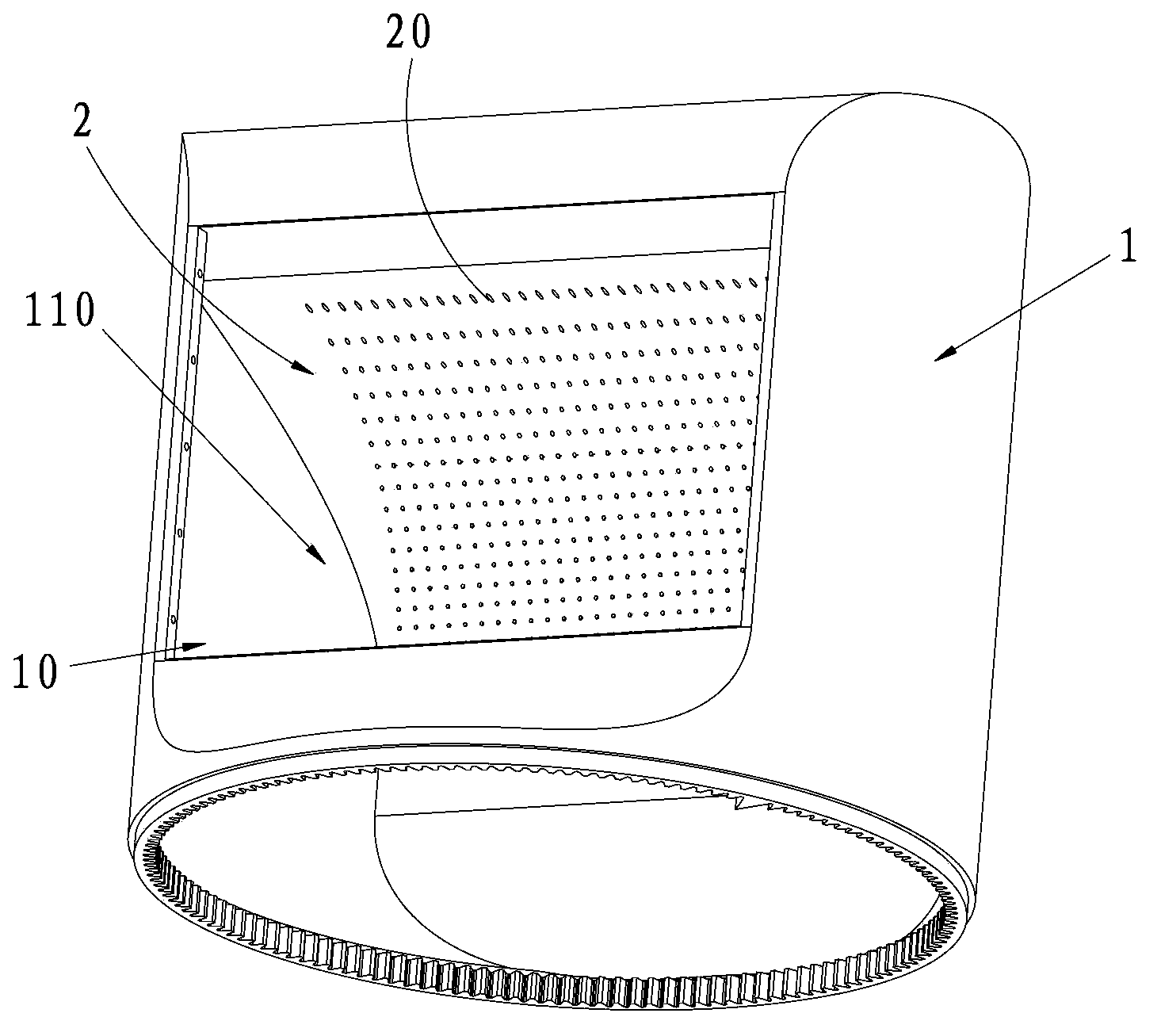

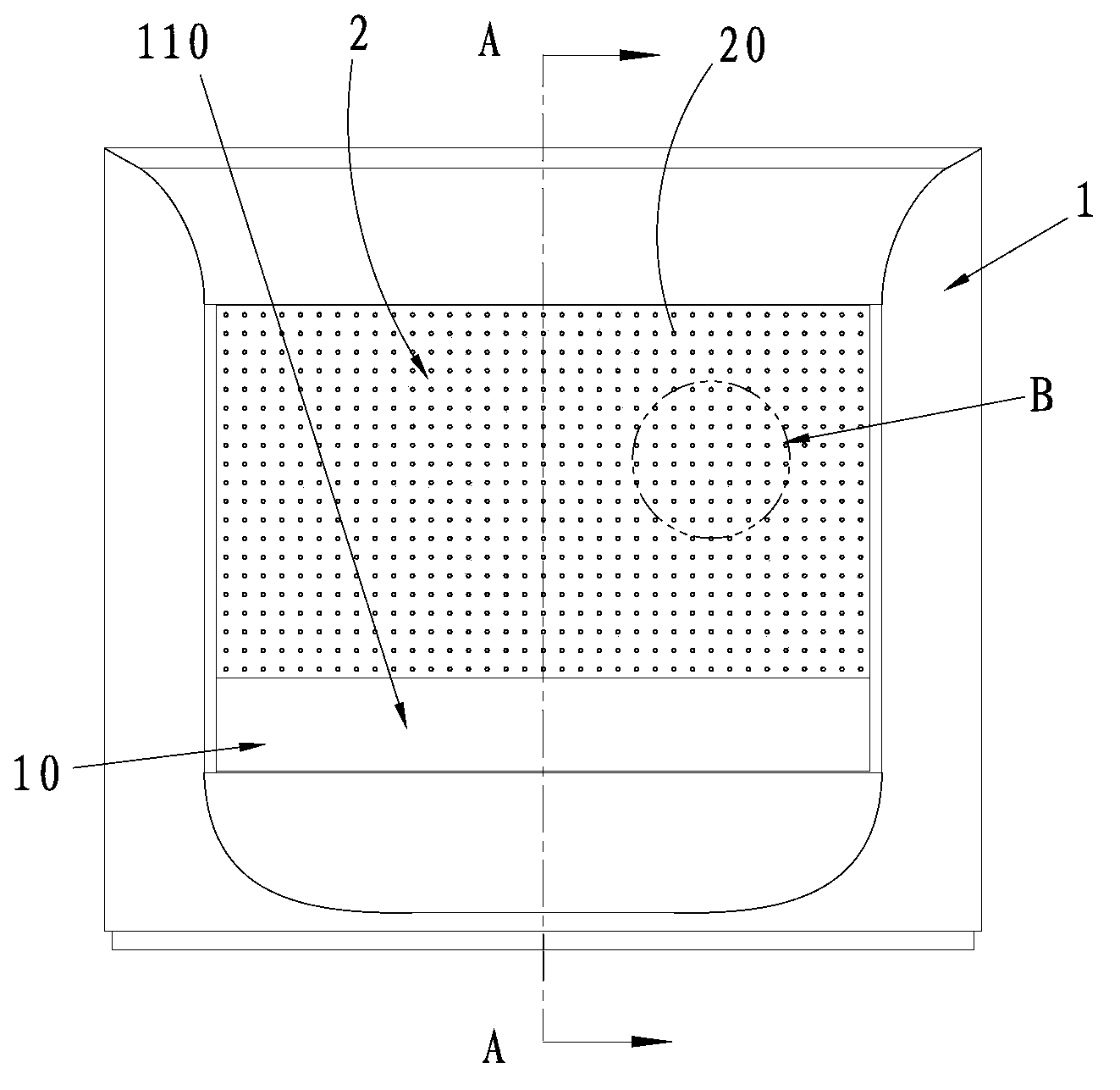

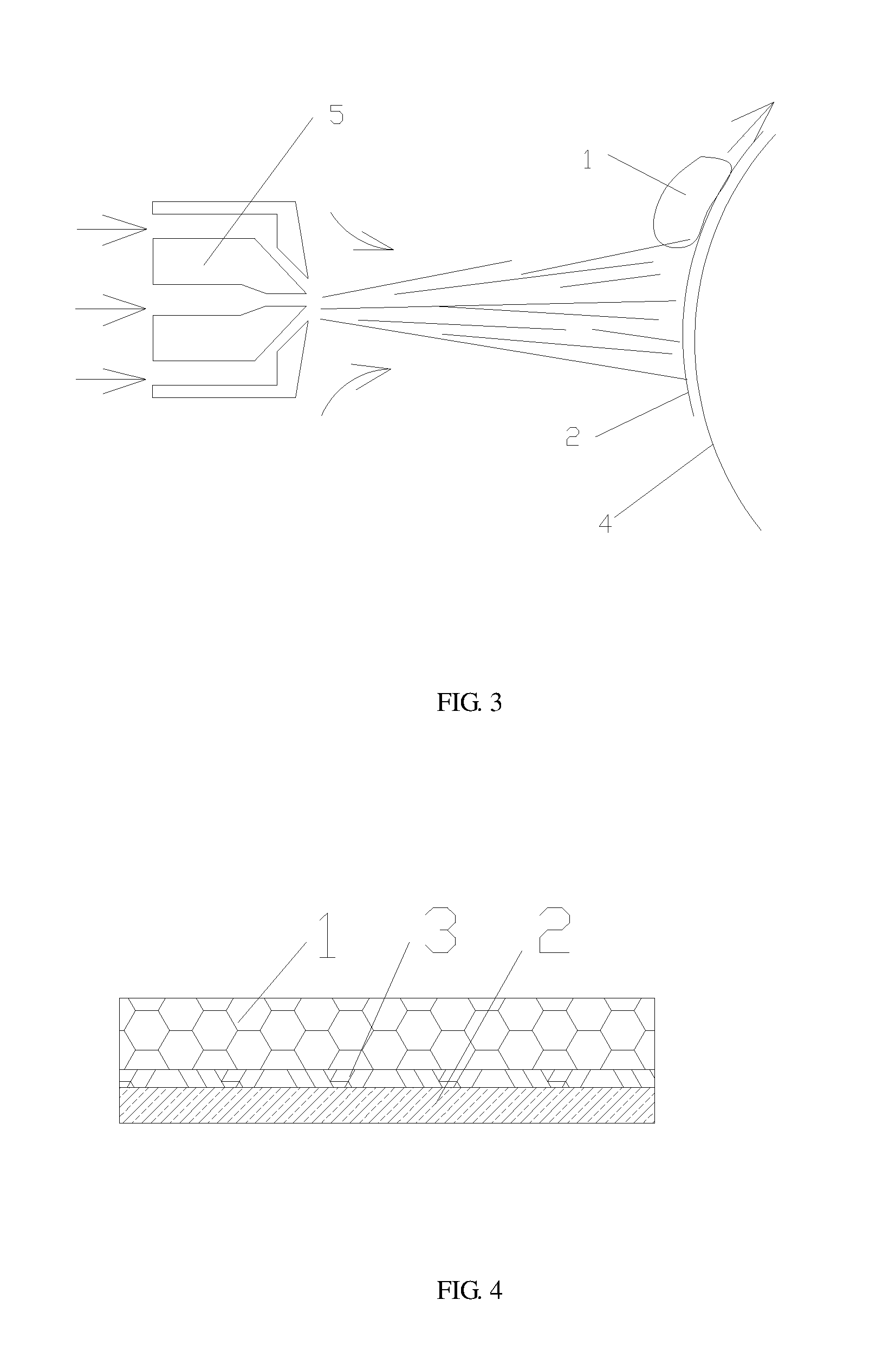

Noise reduction structure of indoor unit of air conditioner, indoor unit of air conditioner and air conditioner

ActiveCN103383140AImprove user experience comfortLow costNoise suppressionLow noiseMicro perforated plate

A control apparatus for reducing noise of an air conditioner indoor cabinet comprises an air outlet arranged on the indoor cabinet and an air-out plate attached to the air outlet. Pressurized air flow passes through the air-out plate and is then delivered out of the indoor cabinet from the air outlet. The air-out plate is provided with micro pores and / or micro slits. The porosity of the micro pores and / or micro slits is 3% to 5%. The micro pores are arranged in a square or a regular triangle shape. The diameter of the micro pores is 1 mm to 2 mm, and / or the width of the micro slits is 1 mm to 2 mm. The micro slits are transversely, longitudinally, obliquely, or crosswise arranged. A cavity is arranged at the back of the air-out plate. The thickness of the cavity is 5 to 20 cm. The outward side of the cavity is provided with a sound absorption layer. The apparatus of the invention has the characteristics of simple and reasonable structure, easy processing, low noise, wide scope of application, high sound absorption coefficient, and wide sound absorption frequency, and can effectively reduce the noise of the air conditioner indoor cabinet.

Owner:MIDEA GRP CO LTD

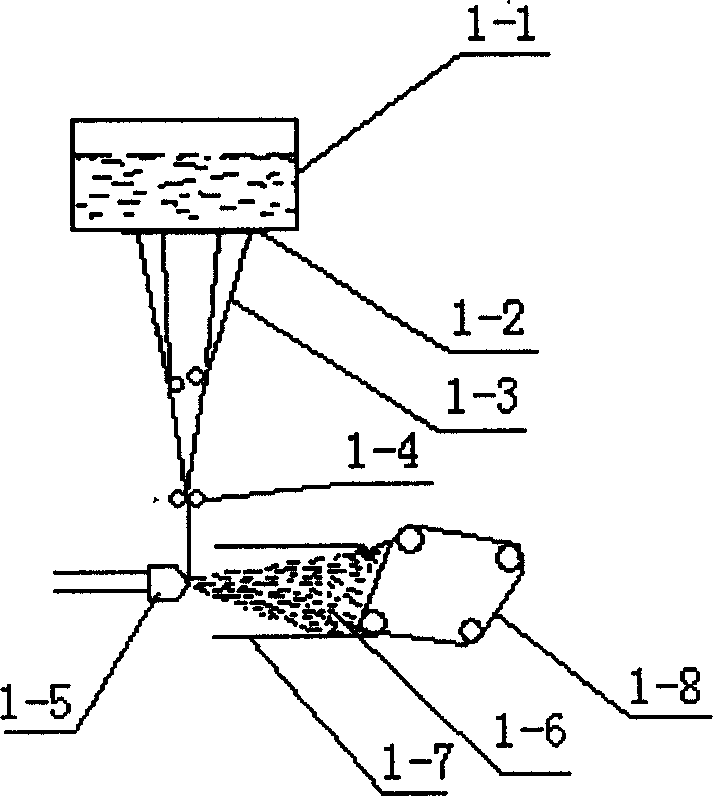

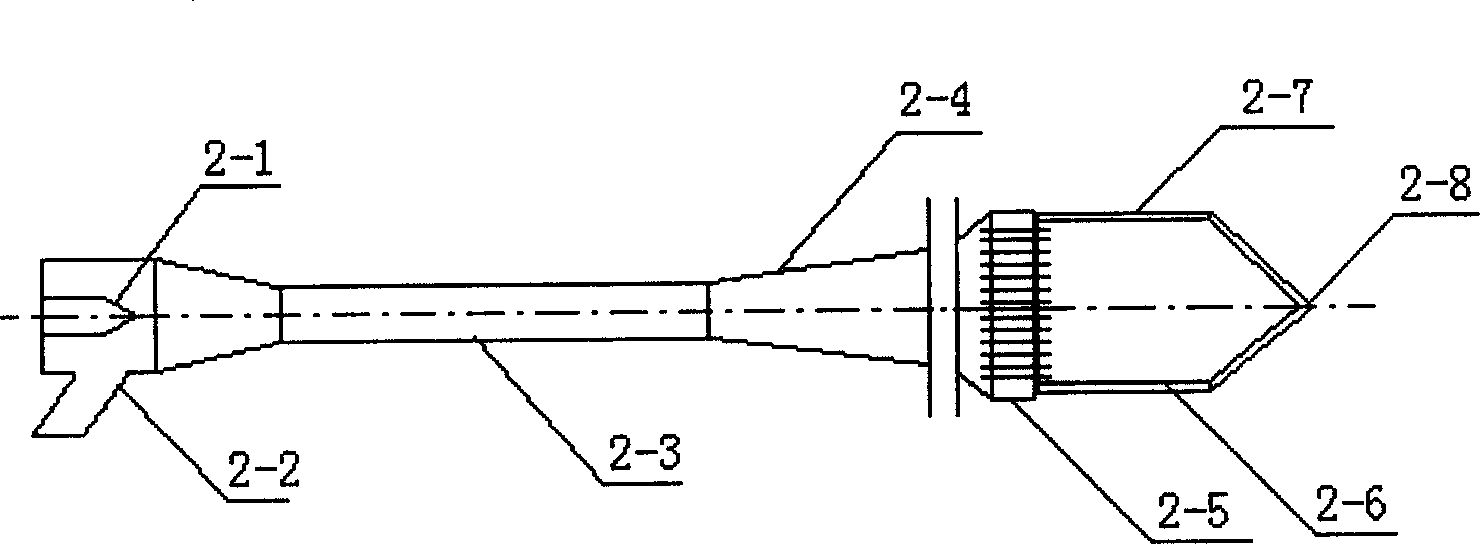

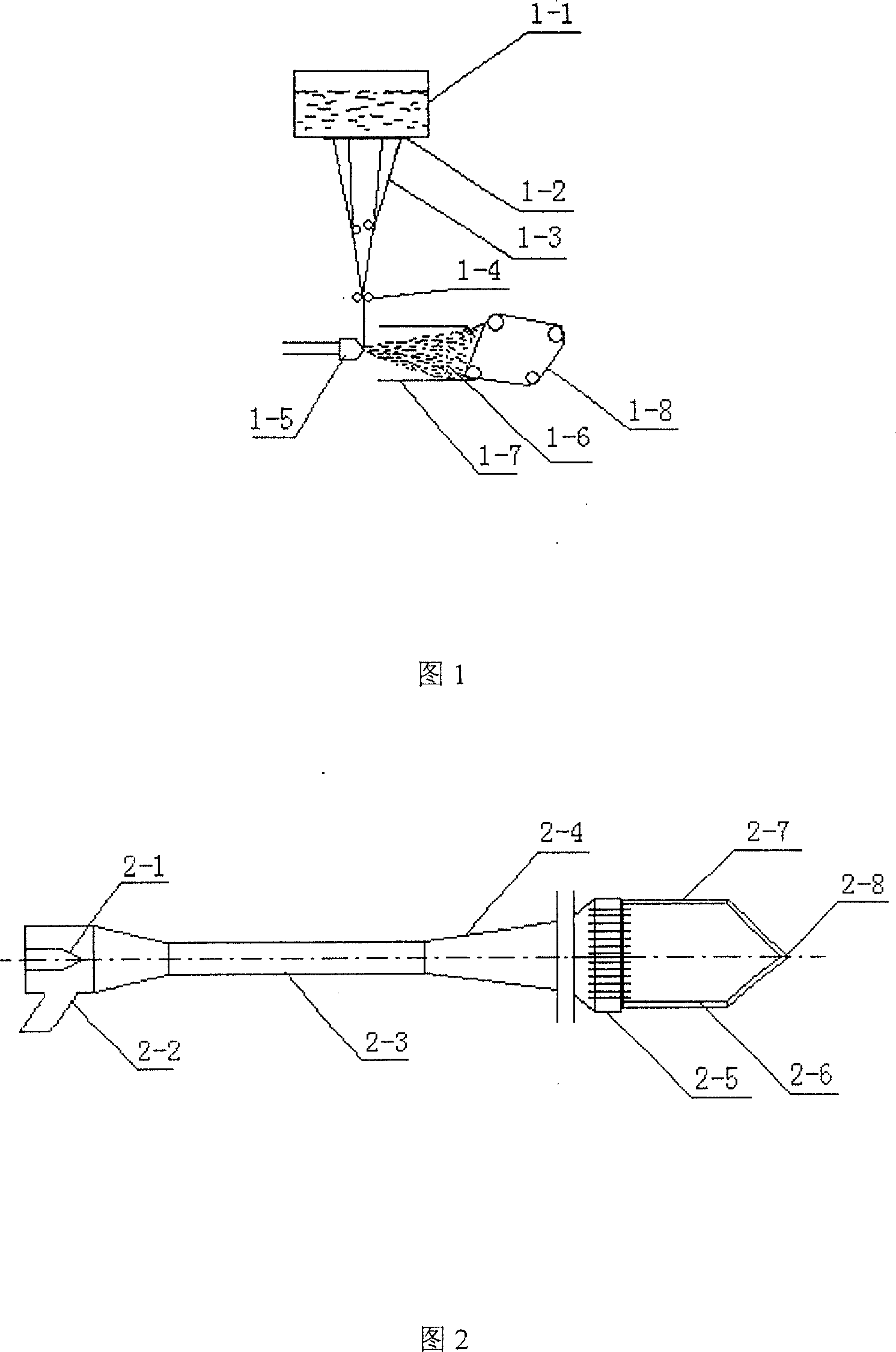

Nano-grade glass fibre cotton and mfg. technology and apparatus thereof

InactiveCN1623945AHigh sound absorption coefficientHigh-quality sound-absorbing materialGlass making apparatusGlass fiberFiber

Owner:HOHAI UNIV

Dense-graded asphalt concrete with continuous skid-resistant and noise-reduction functions

ActiveCN102795813AHigh sound absorption coefficientGood noise reductionCeramicwareTricalcium silicateOptoelectronics

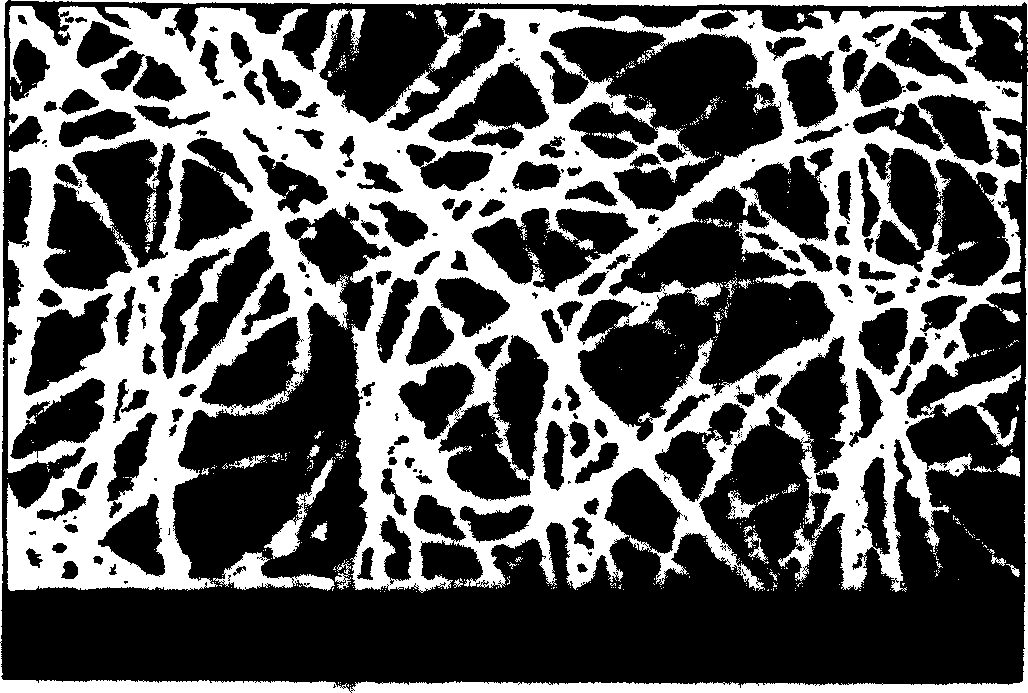

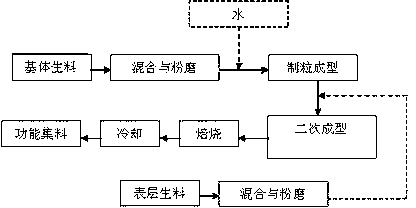

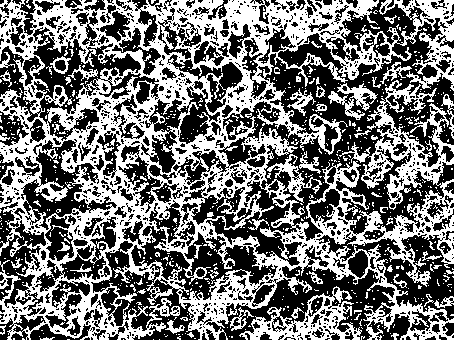

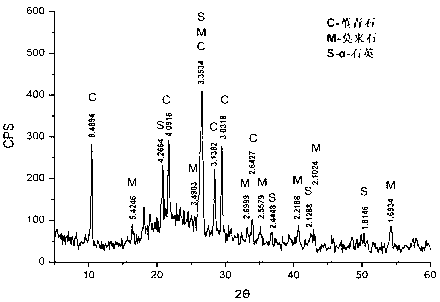

The invention relates to a dense-graded asphalt concrete with continuous skid-resistant and noise-reduction functions. The dense-graded asphalt concrete is prepared from a coarse aggregate, a fine aggregate, packing and asphalt according to the matching requirements of dense-graded asphalt concrete. The dense-graded asphalt concrete is characterized in that the coarse aggregate comprises the following components in percentage by weight: 0-50% of common coarse aggregate and 50-100% of functional aggregate, wherein the functional aggregate is of a core-shell structure and composed of a porous core matrix and an alkaline surface activated shell layer, the porous core matrix takes mullite as a main ore phase and formed into a continuous phase, air holes are distributed in the continuous phase, the diameters of the air holes are distributed in a multistage mode, and the small holes mainly include micron small holes; and the ore phase of the alkaline surface activated shell layer mainly comprises dicalcium silicate, tricalcium silicate, tricalcium aluminate and tetracalcium aluminoferrite. The dense-graded asphalt concrete disclosed by the invention is good in bearing capacity, excellent in water damage resistance and continuous skid-resistant and noise-reduction functions and good in durability, and has a broad application prospect.

Owner:WUHAN UNIV OF TECH

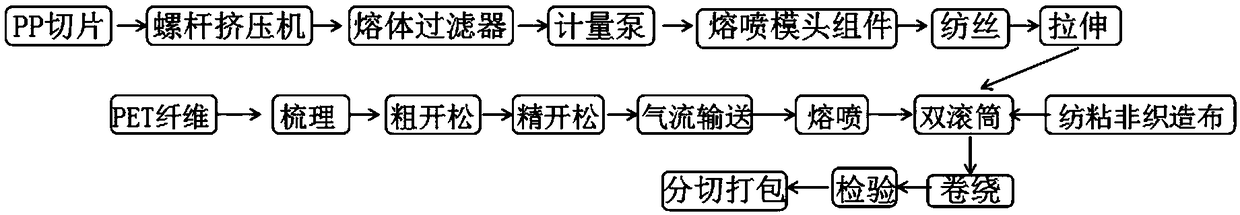

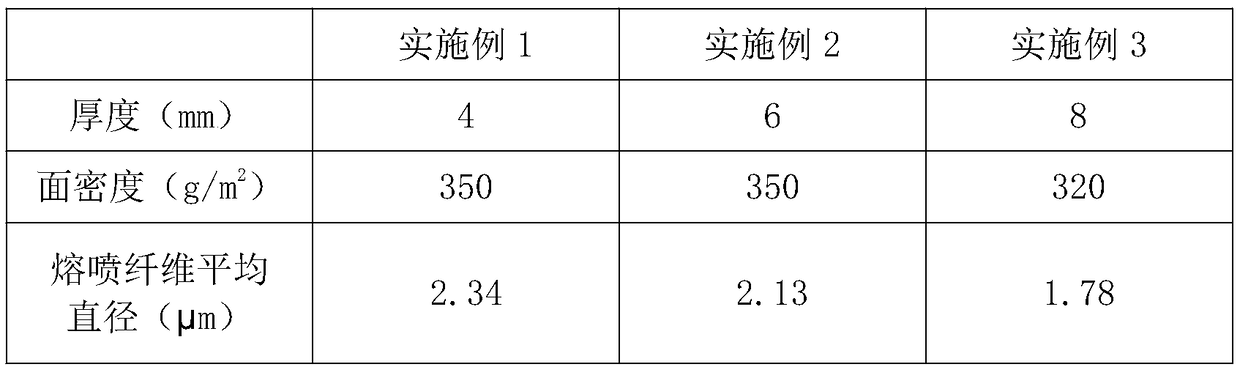

Production technology of sound absorbing cotton formed by compounding short fiber and melt-blowing

InactiveCN108823814AHigh sound absorption coefficientWide sound absorption frequencyMelt spinning methodsNon-woven fabricsEngineeringMelt blowing

The invention discloses a production technology of sound absorbing cotton formed by compounding short fiber and melt-blowing. Compared with a traditional technology, two-time opening technology, an airflow wind supplement conveying mechanism, double-roller receiving composite forming technology are mainly added. The production technology of the sound absorbing cotton formed by compounding the short fiber and melt-blowing has the advantages that equipment is advanced, the technology is simple, it is noticed that the temperature is controlled on the original basis, the prepared sound absorbing cotton not only has excellent properties of light weight, sound absorption, good sound insulation performance, good hydrophobicity, good plasticity, flame retardance and the like, but also is odorless,waterproof, dampproof, good in air permeability, anti-staining and antibacterial, and has a wide application prospect and market value.

Owner:芜湖跃飞新型吸音材料股份有限公司

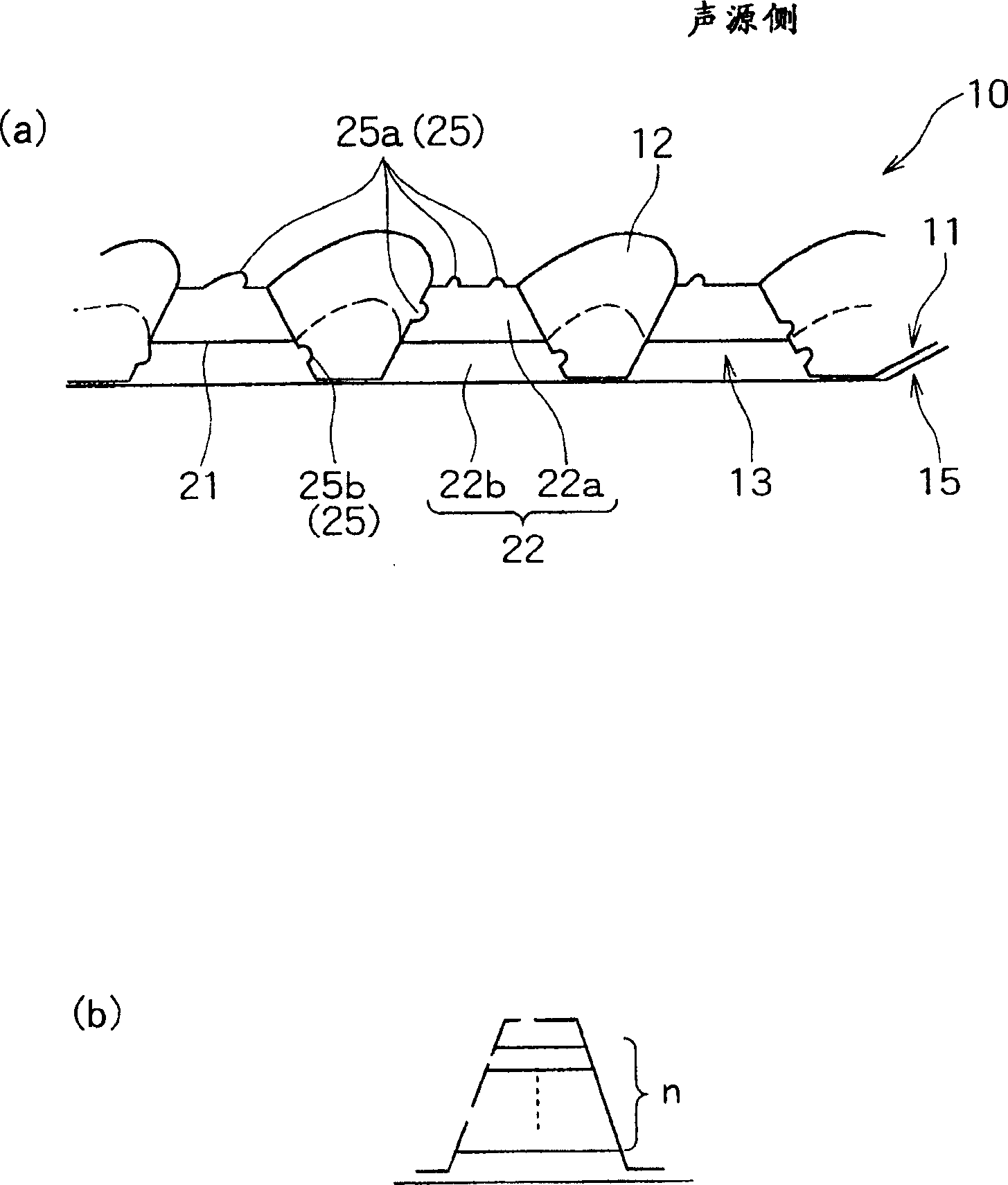

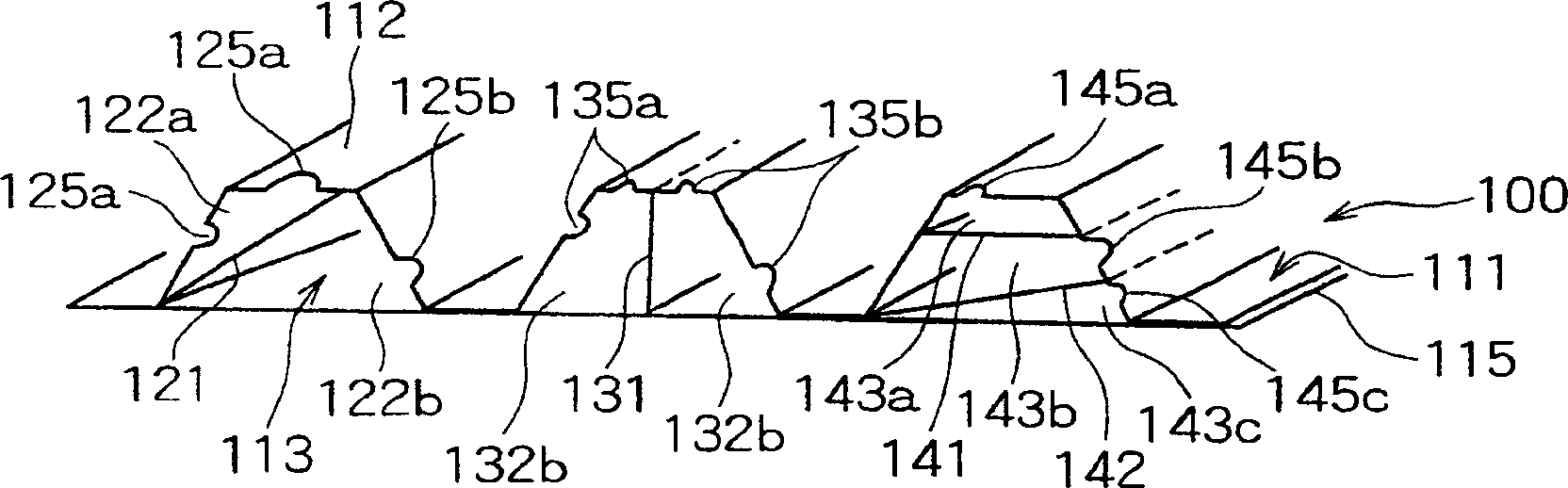

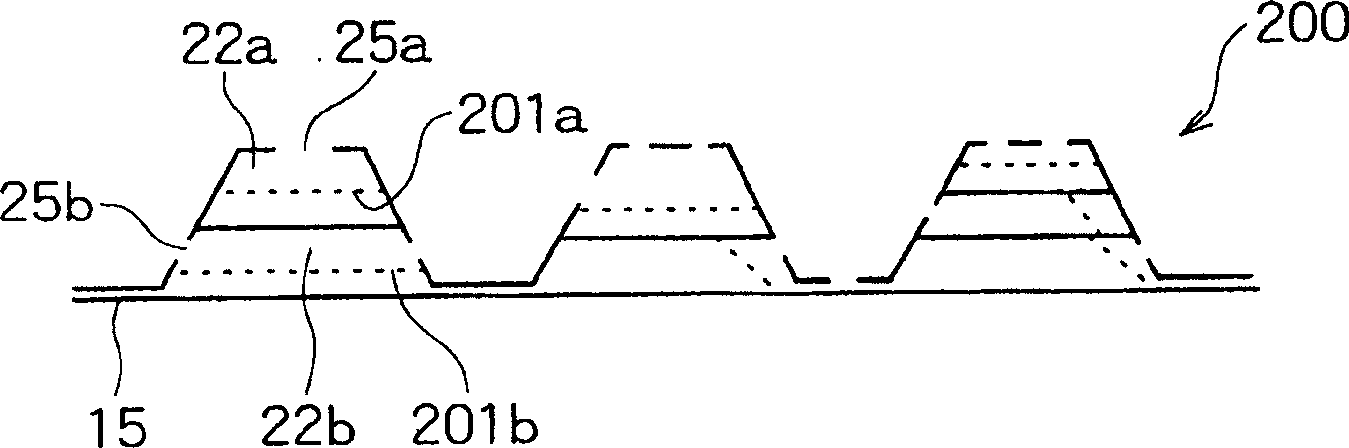

Sound-absorbing structure body

InactiveCN1754202ASound-absorbing band extensionHigh sound absorption coefficientVehicle componentsSound producing devicesEngineeringRidge

A laminated structure body with a ridge-groove board (11) with a large number of ridges and grooves and with a closing board (15) joined to the ridge-groove board so as to close one side of the ridge-groove board to form a hollow portion (13). In the laminated structure body are provided a partition board (21) for partitioning the hollow portion (13) into two or more partitioned spaces (22a, 22b) and two or more hole groups (25a, 25b) opened in the ridge-groove board so as to be communicated with each of the partitioned spaces (22a, 22b) partitioned into two or more spaces. Thus a sound-insulating and -absorbing body is formed.

Owner:KOBE STEEL LTD

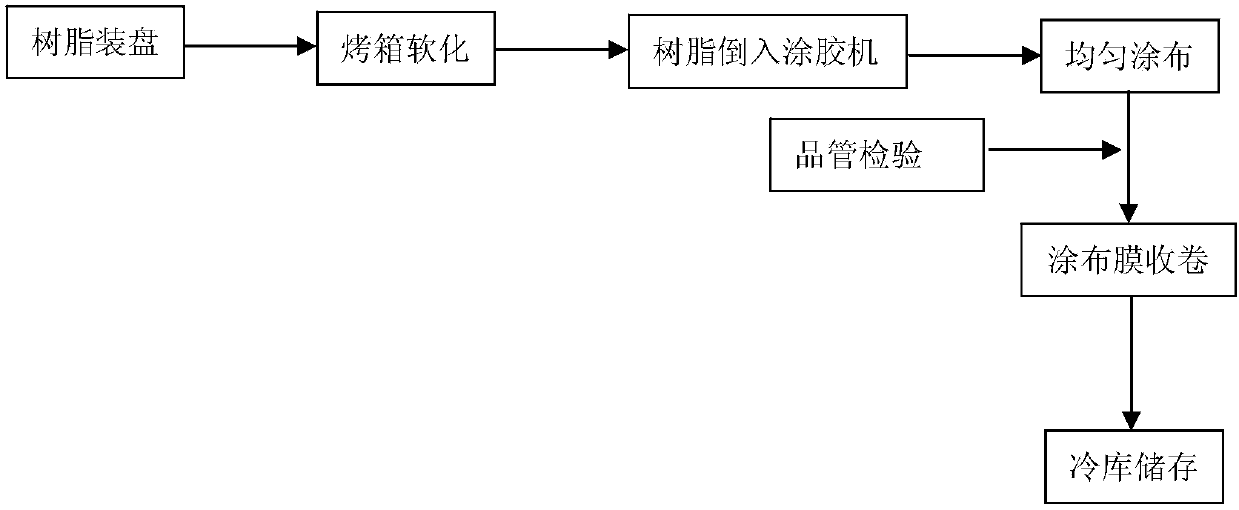

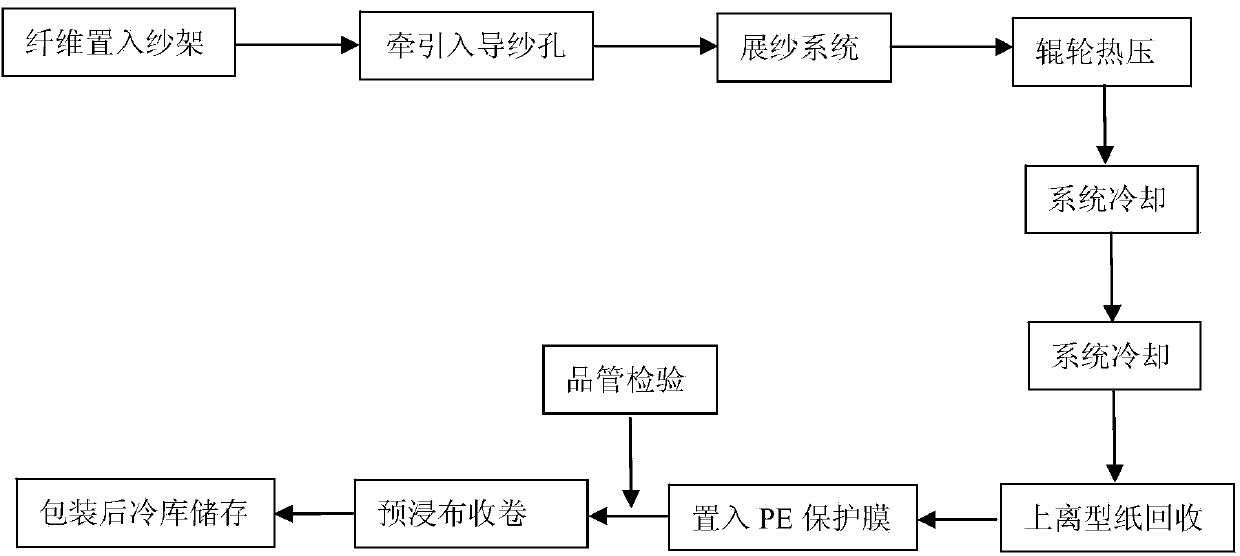

Basalt fiber prepreg and preparation method thereof

The invention discloses a basalt fiber prepreg comprising basalt fiber, epoxy resin and release paper, wherein the epoxy resin is soaked into a basalt fiber layer; and the release paper is directly attached to the outer surface of the basalt fiber layer. In addition, the invention discloses a two-step hot melting preparation method of the basalt fiber prepreg, and the preparation method comprises the steps of film preparation and presoaking. The method disclosed by the invention is simple, and the prepared basalt fiber prepreg is favorably applied to the market field of composite materials such as plates, fishing poles and profiled bars. The basalt fiber and a product thereof have abnormally excellent performances on the following aspects of remarkable high temperature resistance and thermal shock resistance, relatively low heat conduction coefficient, high elasticity modulus and tensile strength, good chemical stability, relatively high sound absorption coefficient, favorable electric insulation and dielectric properties, relatively low moisture absorptivity and natural silicate intermiscibility.

Owner:SUZHOU SUYUE NEW MATERIAL

Glass fiber reinforced polyester composite filament and preparation method thereof

The invention relates to the field of chemical fiber manufacturing, in particular to a glass fiber reinforced polyester composite filament and a preparation method thereof. The composite filament is formed by mixing and compounding glass fiber and polyester. The fineness ratio of the glass fiber to the polyester is 1.8-3. The specific preparation method comprises the following steps: 1) pre-treating the glass fiber, 2) stranding, 3) false twisting, 4) sizing, 5) oiling and 6) winding molding to obtain a finished composite filament product. The glass fiber reinforced polyester composite filament with good performances can be obtained by the method.

Owner:ZHEJIANG HAONENG TECH CO LTD

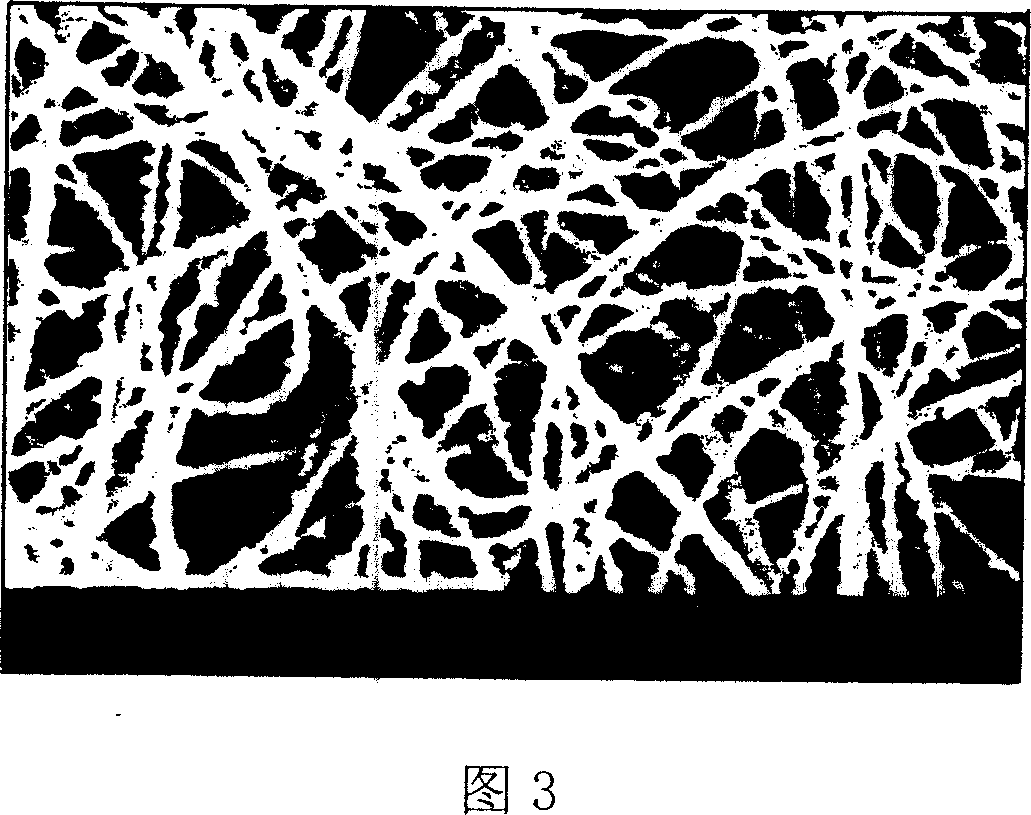

Meltblown nonwoven fabric and uses thereof

InactiveUS20150233030A1Low bulk densitySatisfactory sound absorption performanceLayered productsFilament/thread formingPolymer scienceFiltration

A meltblown nonwoven fabric is provided having thermoplastic resin fibers having an average fiber diameter of 0.1 to 10 μm, a bulk density of not more than 36 kg / m3 and an air permeability, as measured by a Frazier type method at basis weight of 200 g / m2, of 3 to 100 cc / cm2 / sec. The meltblown nonwoven fabric has a low bulk density and is excellent in sound absorption performance, oil adsorption performance, heat insulation performance, dust collection performance and filtration performance. Since the meltblown nonwoven fabric can be formed from one kind of a resin composition, it can be simply and easily produced as compared with the case of using mixed fibers or conjugated fibers formed from many kinds of resins, and the resulting meltblown nonwoven fabric can have uniformity and no variability of properties.

Owner:MITSUI CHEM INC

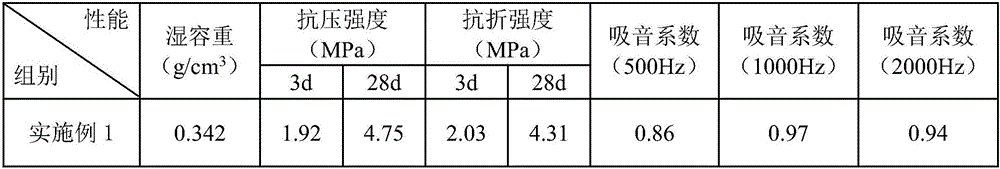

Sound absorbing material and preparation method thereof

The invention relates to a sound absorbing material and a preparation method thereof. The sound absorbing material is prepared by the following steps of using wide-source water-quenching copper slag and processing plant wastewater containing collagen as main raw materials; mixing, foaming, injecting into a die, drying, and curing, so as to obtain the sound absorbing material. The prepared sound absorbing material has the advantages that the wet unit weight is low, the weight is light, the compressive strength and bending strength are high, the sound absorbing coefficient is high, the manufacturing cost is low, and the processing is simple; compared with common fiber sound absorbing material, the characteristics of water proofing, flame retardancy and corrosion resistance are realized; the durability is strong, the sound absorbing material is very suitable for governing various noises, such as industrial plants, KTV (Karaoke), subways, highways, railways and airports, and the application prospect is wide.

Owner:GUANGZHOU KAIYAO ASSET MANAGEMENT CO LTD

Preparation process of ceramsite asphalt pavement material

InactiveCN112551948AImprove mechanical propertiesImprove barrier propertiesCross linkerThermal stability

The invention discloses a preparation process of a ceramsite asphalt pavement material. The preparation proces comprises the following steps: preparing the following raw materials in parts by weight:30-50 parts of asphalt, 1-2 parts of modified nano filler, 10-13 parts of modified shale ceramsite, 5-10 parts of SBS modifier, 3-5 parts of basalt fiber, 2-4 parts of diatomite, 5-10 parts of rubberpowder, 0.3-0.5 part of dispersing agent, 0.1-0.3 part of cross-linking agent and 0.1-0.3 part of antioxidant; the ceramsite asphalt pavement material is prepared by mixing the modified shale ceramsite, the modified nano-filler, asphalt and other fillers, and the modified nano-filler is added into the ceramsite asphalt pavement material, so that the mechanical property, barrier property and thermal stability of the ceramsite asphalt pavement material are improved, and the ceramsite asphalt pavement material has fatigue resistance, low-temperature crack resistance and water stability by utilizing a special physical structure of the diatomite and high damping and shock absorption characteristics of the basalt fibers.

Owner:武汉极限光科技有限公司

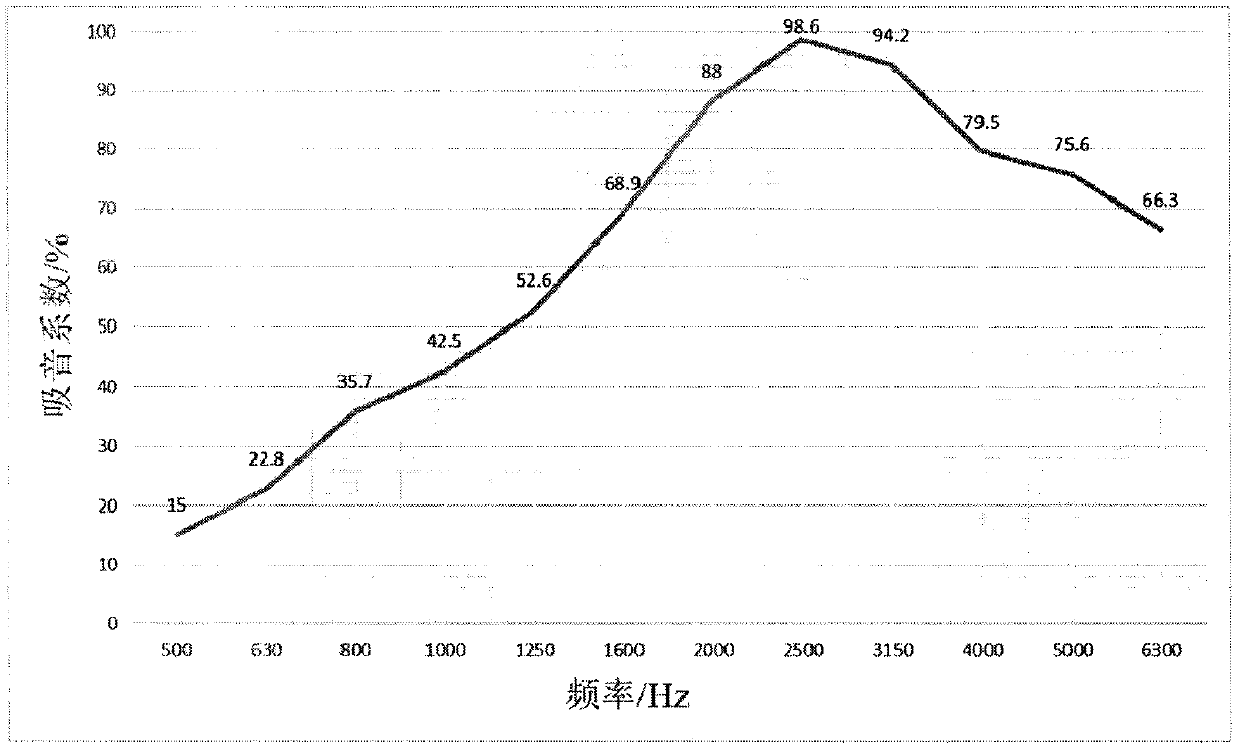

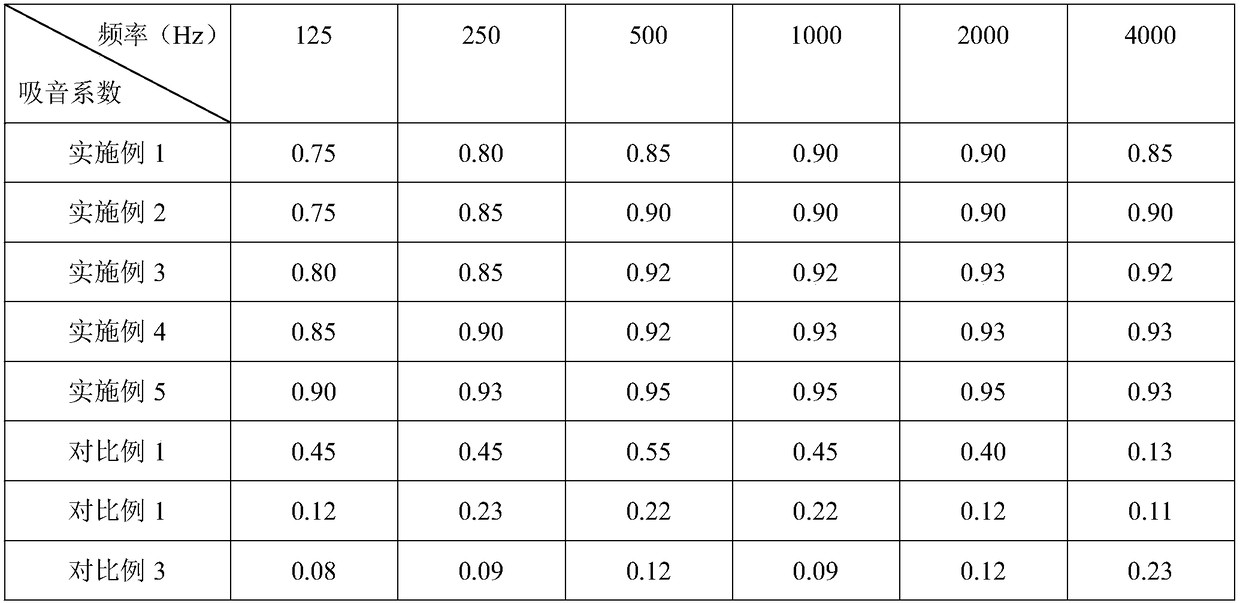

High Sound Absorption Coefficient Expanded PTFE Composite Fiber Cotton

ActiveUS20160121588A1High sound absorption coefficientReduce noiseSynthetic resin layered productsVehicle componentsTetrafluoroethylenePolymer science

The present invention discloses a high sound absorption coefficient expanded PTFE composite fiber cotton, comprising a melt-blown high polymer fibrous layer and an expanded PTFE film layers or a modified film layer of expanded PTFE, the modified film layer of expanded PTFE is made by conducting modification treatment to a PTFE film; the high sound absorption efficiency expanded PTFE composite fiber cotton is made by combining the melt-blown high polymer fibrous layer and the expanded PTFE film layer or the modified film layer of expanded PTFE. Thus, the present invention with better full-frequency sound absorption capability and marked full-frequency sound absorption effect can be bound in a large area or filled on automobiles' engine hoods, body racks or the inner side face of automobile trunks to substantially absorb automobile noise; it has advantages such as chemical inertness, waterproof, dustproof, permeable filterability, long service life and weldability.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

Sound-absorbing rigid polyurethane foam composite material for vehicles

The invention discloses a sound-absorbing polyurethane rigid foam composite material for vehicles, which is composed of a component A and a component B. The component A comprises the following raw materials in parts by weight: 40-60 parts of polyether polyol A; 15 to 25 parts of polyester polyol; 10 to 20 parts of polyether polyol B; 2-7 parts of a chain extender; 0.8 to 3.0 parts of a surfactant;0.5 to 1.5 parts of a catalyst; and 2.0 to 4.0 parts of water; the component B is prepared from polymethylene polyphenyl polyisocyanate as a raw material; wherein the polyether polyol A is polypropylene oxide-polyoxyethylene polyol with the functionality of 3 and the molecular weight of 3,000 to 9,000; wherein the polyester polyol is phthalic anhydride polyester polyol with the functionality of 2-3 and the molecular weight of 300-2000; and the polyether polyol B is polypropylene oxide polyol with the functionality of 3-4 and the molecular weight of 300-1000.

Owner:LIMING RES INST OF CHEM IND

Intelligent train tunnel noise generating system based on single chip microcomputer control

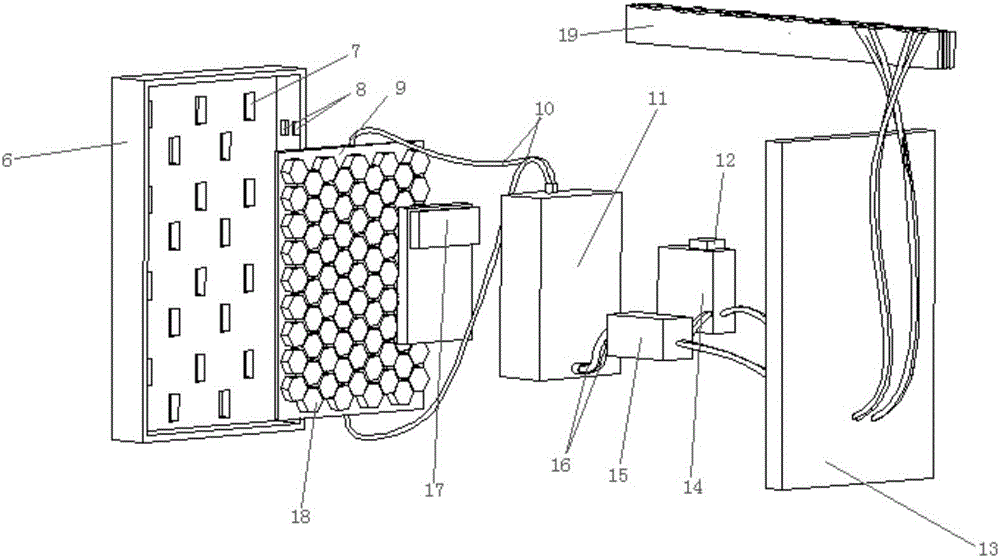

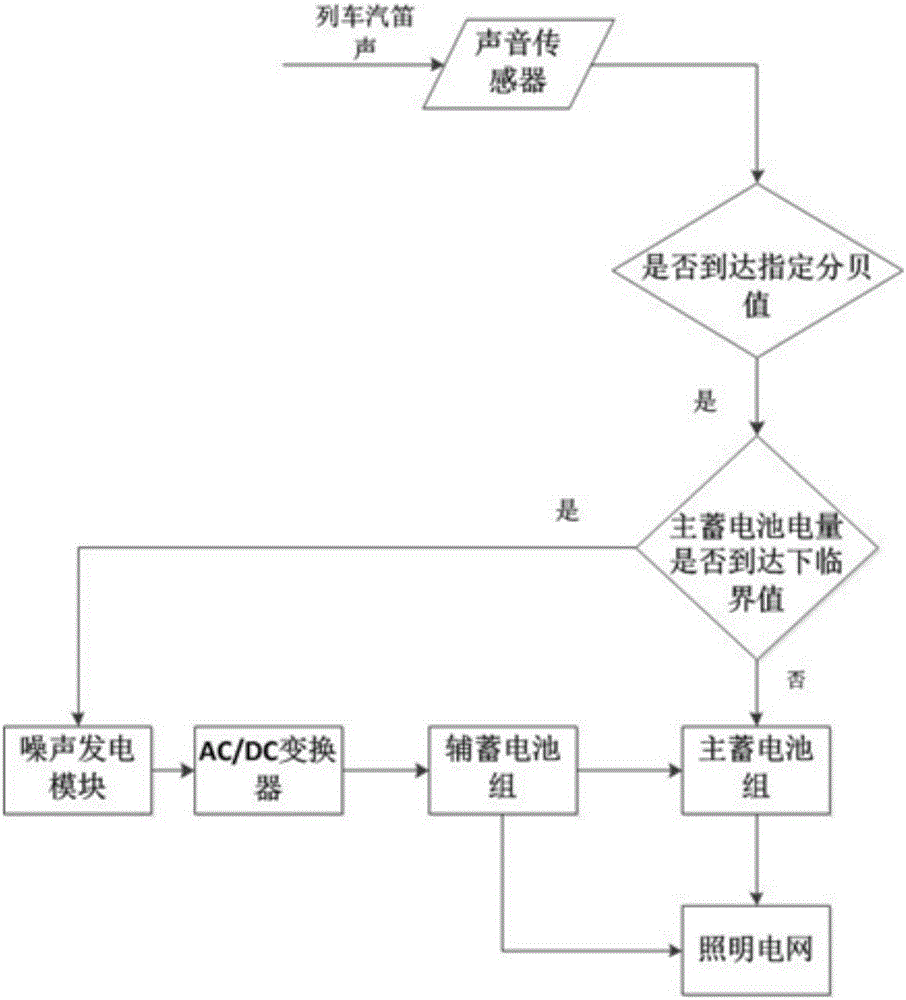

InactiveCN107437904ARealize automatic controlRealize the effect of automatic closingBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesIntelligent lightingEngineering

The invention discloses an intelligent train tunnel noise generating system based on single chip microcomputer control, which comprises a mounting structure and an integrated device (4) connected with the mounting structure, wherein the integrated device (4) comprises a single chip microcomputer processing unit, a noise generating unit, a piezoelectric ceramic generating module connected with the single chip microcomputer processing unit through a data line, a voltage-stabilizing energy storage module and an intelligent control module. Noise generated by the train in the tunnel is used, and through the piezoelectric generating module and the intelligent control module arranged at two sides of the tunnel, electric energy conversion by the tunnel train noise and intelligent lighting control are realized; and the recovery and the utilization of noise energy can be effectively realized, the energy is saved while the purpose of noise reduction is achieved, and the line arrangement in the tunnel is simplified.

Owner:WUHAN UNIV OF TECH

Production process of intelligent odorless automotive interior nanomaterial

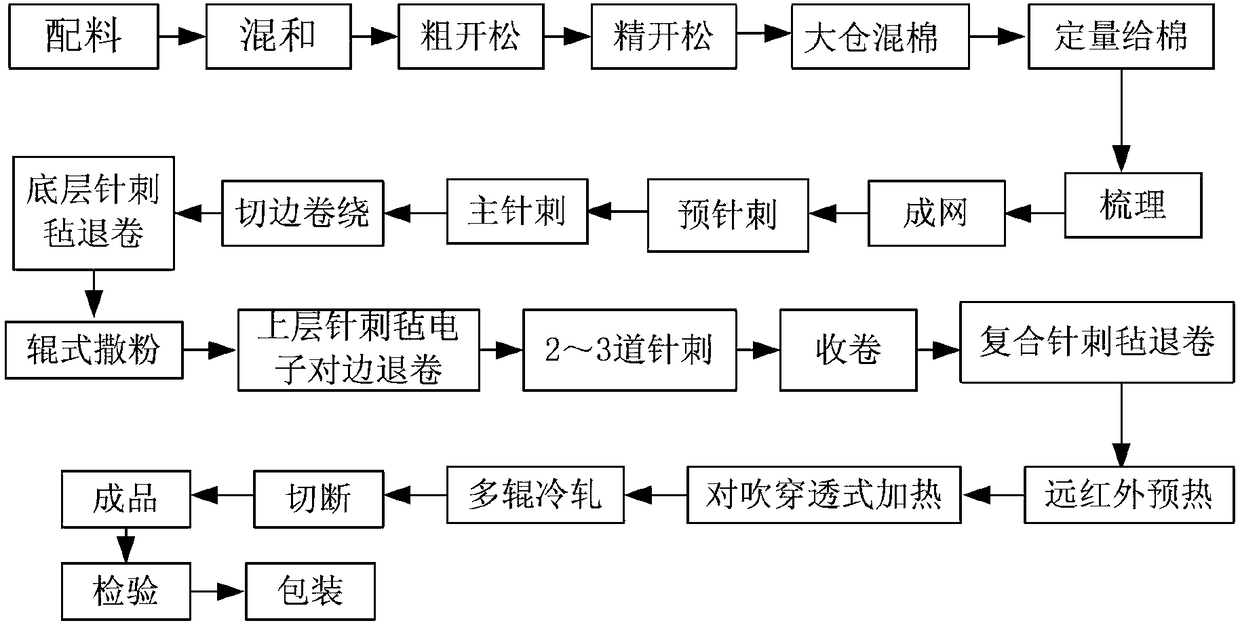

The invention discloses a production process of an intelligent odorless automotive interior nanomaterial and belongs to the technical field of novel material processing. The process comprises materialpreparation, blending, coarse opening, fine opening, large-bin cotton blending, quantitative cotton feeding, carding, netting, pre-needling, primary needing, trimming and winding, unwinding of bottom-layer needled felt, roll type powder scattering, electronic alignment and unwinding of upper-layer needled felt and 2-3 times of needling and composition to obtain composite needled felt, winding, unwinding of the composite needled felt, far infrared preheating, blowing through heating, multi-roll cold rolling, cutting, obtaining of a finished product, inspection and packaging. By means of the process, nano SiO2 powder is composited between two layers of needled felt, the intelligent odorless automotive interior nanomaterial is obtained, the aldehyde release amount reaches the environmental protection standard, the environmental protection grade reaches the grade E0, the flavor is smaller than the grade 1, the sterilization and disinfection capability reaches 95% or above, the sound absorption coefficient is improved by 30%-40%, noise is reduced by 10-15 db and the weight is reduced by 10%-20%.

Owner:大连神润新材料有限公司

Sound absorbing brick capable of reducing noise pollution

InactiveCN108409313AHigh sound absorption coefficientHigh mechanical strengthSound proofingCeramicwareBorideAcoustic noise reduction

The invention relates to the technical field of construction materials, and specifically relates to a sound absorbing brick capable of reducing noise pollution. The sound absorbing brick is mainly composed of diatomite, bio-carbon, ceramic sand, talcum powder, silica micro-powder, zirconium boride, a dispersant, an adhesive and water; wherein the particle size of the bio-carbon is 300 to 400 nm, the bio-carbon is prepared from cactus, sisal hemp, maguey leaf, leaf of gasteria duval, corn straw, ramie, flax, kendir, hemp, undaria pinnatifida, and sea tangle, and silica aerogel is loaded on thebio-carbon. Compared with a conventional sound absorbing brick containing mineral wool fibers, the provided sound absorbing brick has a greater sound absorbing coefficient, is capable of obviously reducing the noise pollution, meets the using requirements, has higher mechanical strength, and is more environmentally friendly.

Owner:长兴科创科技咨询有限公司

Making method of automobile sound-absorption carpet

ActiveCN105082695AExcellent fluffy feelImprove viewing and comfortSynthetic resin layered productsVehicle componentsAbsorption effectEngineering

The invention discloses a making method of an automobile sound-absorption carpet. The carpet is formed by pressing a layer A, a layer B, a layer C and a layer D from top to bottom at high temperature. The preparation method includes the steps that a, opening, mixing, carding, cross lapping, needling forming and raising shaping are performed on 100% fine Danny PET fibers to form the layer A having excellent sound-absorption performance; b, opening, mixing, carding, cross lapping and needling forming are performed on three-dimensional crimped fibers and L-PET fibers to form the layer B having a certain thickness and a certain tightness degree; c, a three-roll hot ironing machine is used for pasting the PE face of a PEPA asymmetrical film of the layer D to the layer B, and then cooling is performed to form PET bottom felt finally; d, a PE film is used for pasting the fabric of the layer A to the face, without the PEPA asymmetrical film, of the PET bottom felt formed in the step c, so that the automobile sound-absorption carpet is formed. The automobile sound-absorption carpet has the advantage that the fine Danny fibers are adopted for achieving the sound-absorption effect of the product according to requirements.

Owner:昆山九子莲汽车隔音材料有限公司

Manufacturing method of environment-friendly saloon car sound insulating pad

ActiveCN102785370AMeet higher requirements for safety performanceSimple preparation processManufacturing technologyPalm fiber

The invention relates to a manufacturing method of a saloon car sound insulating pad, particularly relates to a novel manufacturing method of the saloon car sound insulating pad with an environment protection characteristic, and belongs to the manufacturing technology field of auto interior decoration. The manufacturing method comprises the steps: firstly, manufacturing a forming mold; secondly, using a palm fiber and a natural latex to blend so as to obtain a base material of the sound insulating pad; pressing and molding the base material of the sound insulating pad in a thermal forming mold to obtain a semi-finished product of the sound insolating pad; at last, putting a fabric in the mold and pressing and flattening the fabric and the semi-finished product, so as to obtain the environment-friendly saloon car sound insulating pad. According to the manufacturing method, the manufacturing process is simple and is similar to that of reconstituted cotton; only the innovation of the material gives a novel connotation to a traditional saloon car sound insulating pad; the sound absorption coefficient is greatly improved; at the same time, the improvement of the environment protection characteristic satisfies the higher demand of people on the safety performance of a passenger car; and the sound insulating pad is an environment-friendly product and achieves the goal of recycling on a certain technology basis.

Owner:WUXI GISSING AUTO PARTS CO LTD

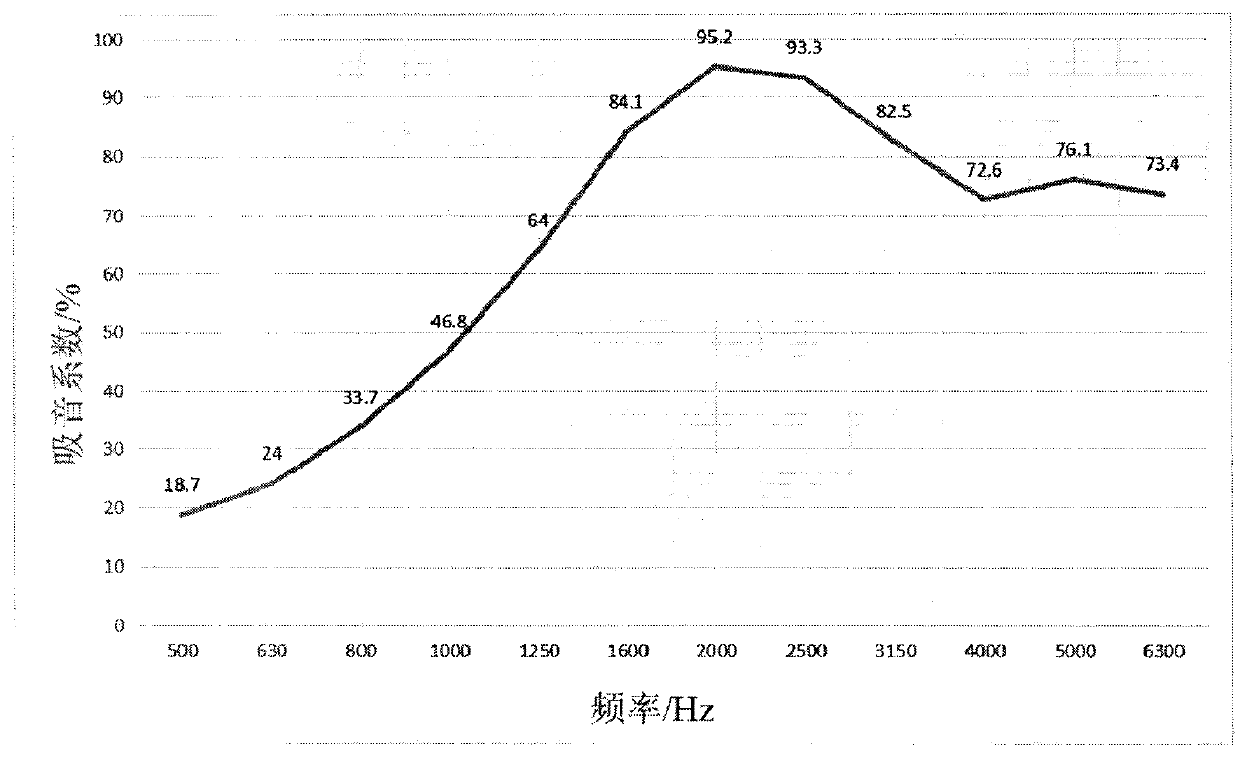

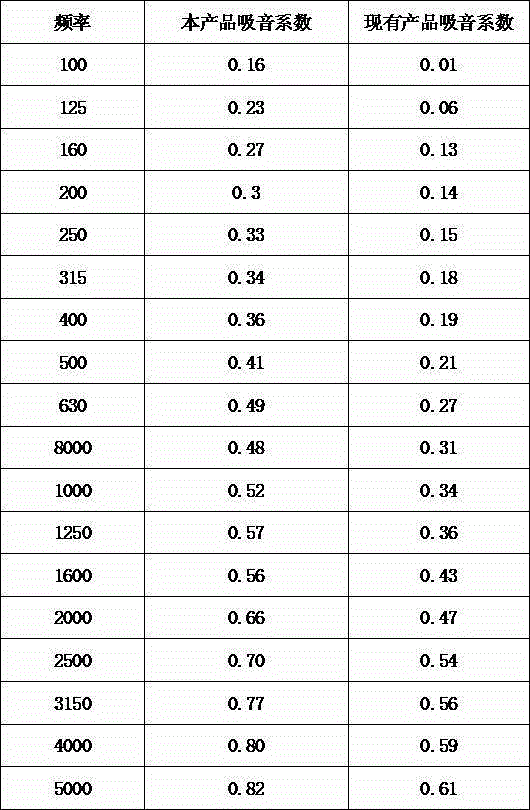

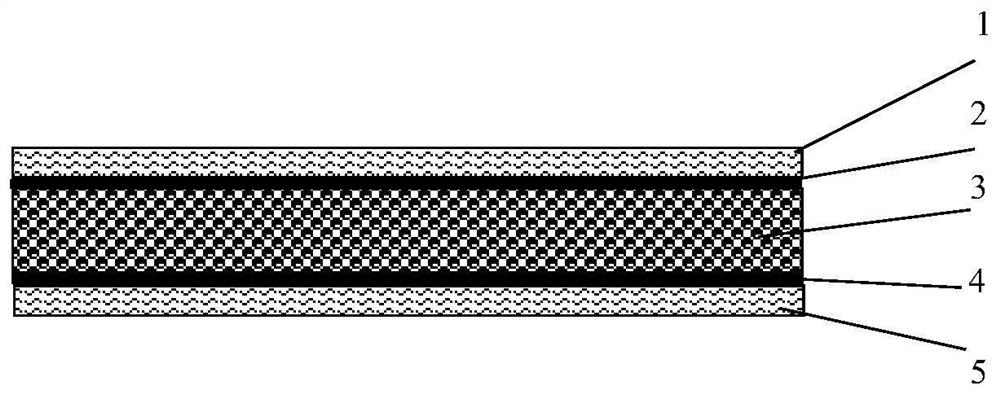

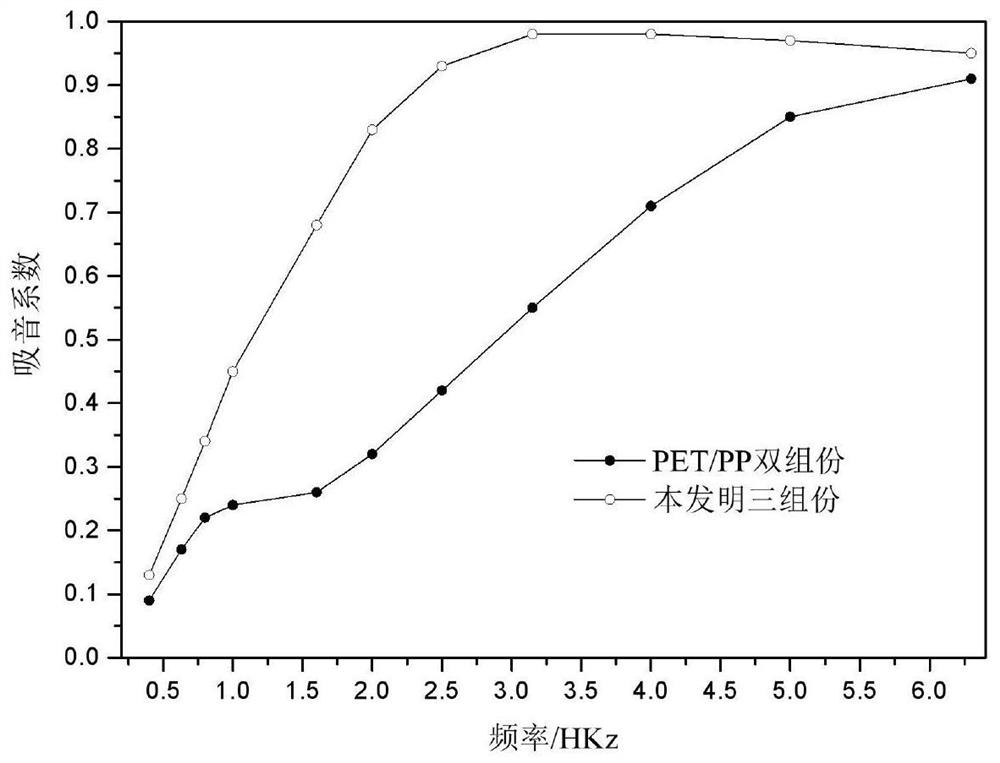

Three-component sound-absorbing cotton and preparation method thereof

InactiveCN111716859AHigh sound absorption coefficientImprove sound absorptionSynthetic resin layered productsLaminationAdhesive cementPolymer science

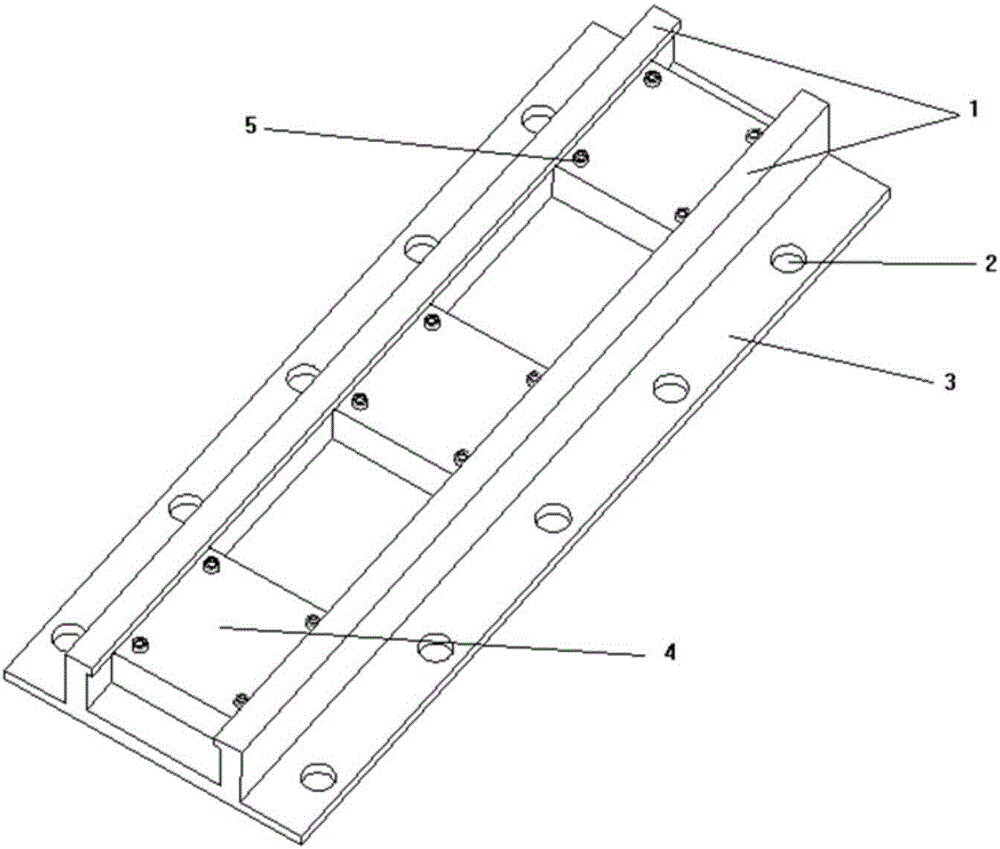

The invention discloses three-component sound-absorbing cotton and a preparation method thereof, and belongs to the technical field of sound-absorbing materials. The three-component sound-absorbing cotton comprises three components, wherein an upper surface layer (1), a first adhesive layer (2) a middle layer (3), a second adhesive layer (4) and a lower surface layer (5) are sequentially arrangedin a stacked mode from top to bottom. The middle layer (3) is made of polyurethane porous foam materials, the upper surface layer (1) and the lower surface layer (5) are both made of mixed fibers of polyethylene glycol terephthalate fibers and polypropylene fibers, and the first adhesive layer (2) and the second adhesive layer (4) are both made of adhesives. The invention further discloses the preparation method of the three-component sound-absorbing cotton. The three-component sound-absorbing cotton is of a three-layer structure, has excellent sound-absorbing and sound-insulating effects, andis small in overall surface density.

Owner:GUANGXI DEFUTE TECH CO LTD

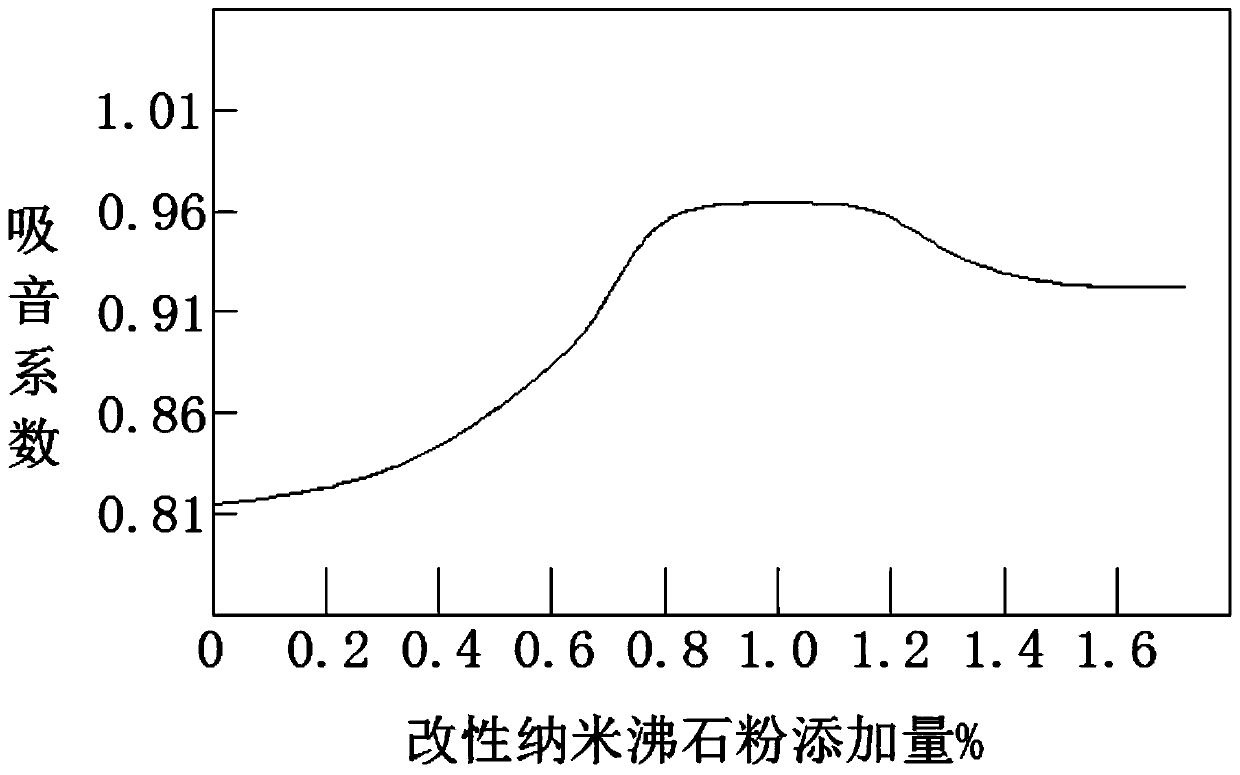

Melamine sponge

The invention discloses a melamine sponge, and relates to the technical field of the melamine sponge. The melamine sponge is prepared by the following steps: (1) preparing an ethanol / ammonia water mixed solution; (2) modifying nano zeolite powder; (3) preparing a basic treatment solution; and (4) melamine sponge treatment. According to the melamine sponge, the internal aperture ratio is as high as99%, and the prepared melamine sponge has a relatively high sound absorption coefficient, which indicates that the prepared melamine sponge has an excellent silencing effect so that the melamine sponge can be applied to the field of sound insulation and plays a great role in reducing sound and noise.

Owner:郑州峰泰纳米材料有限公司

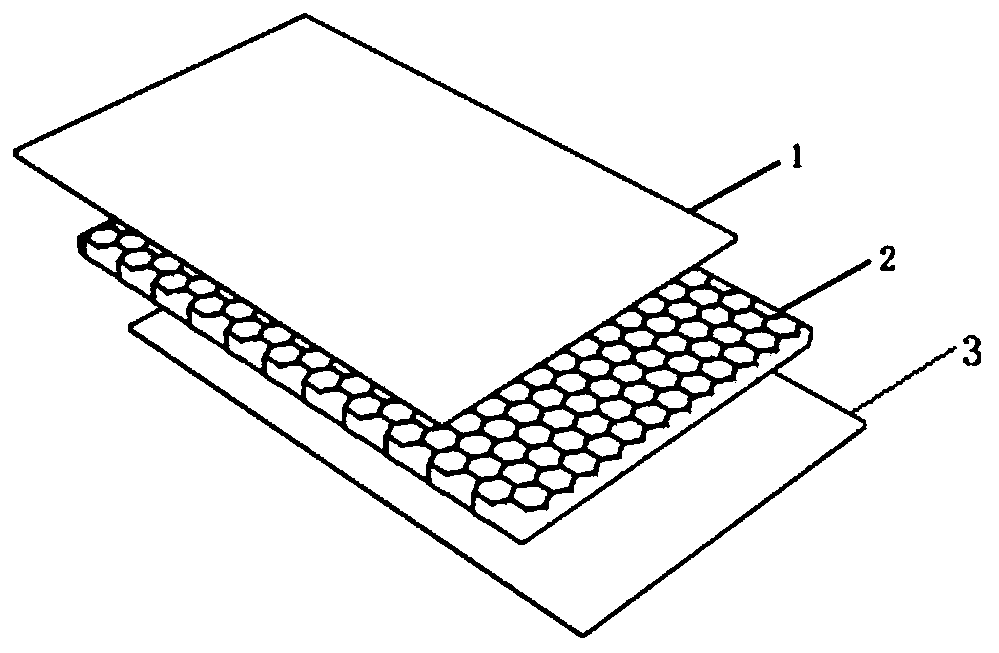

Eucalyptus veneer veneered wood-based composite board and preparation method thereof

ActiveCN110757917AHigh sound absorption coefficientImprove sound insulationLamination ancillary operationsLaminationWood veneerWood fibre

The invention provides a eucalyptus veneer veneered wood-based composite board and a preparation method thereof, and belongs to the technical field of composite boards. The eucalyptus veneer veneeredwood-based composite board provided by the invention is characterized by comprising a honeycomb composite layer and eucalyptus veneer layers adhered to two sides of the honeycomb composite layer, wherein the matrix of the honeycomb composite layer is a honeycomb plate core; the pores of the honeycomb plate core are filled with fillers; and the fillers comprise buckwheat hulls, wood fibers and inorganic adhesives. According to the eucalyptus veneer veneered wood-based composite board, a honeycomb core layer of the composite board is filled with the buckwheat hulls, the wood fibers and the inorganic adhesives, so that the compression resistance of the board is improved, and the sound insulation effect of the composite board is further improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

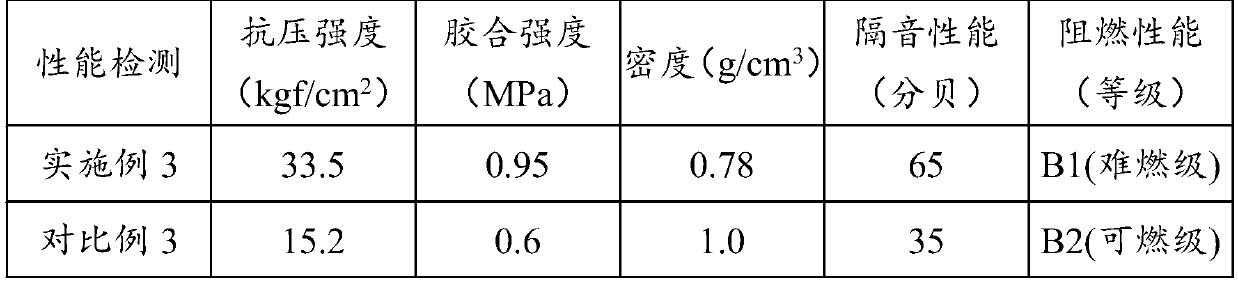

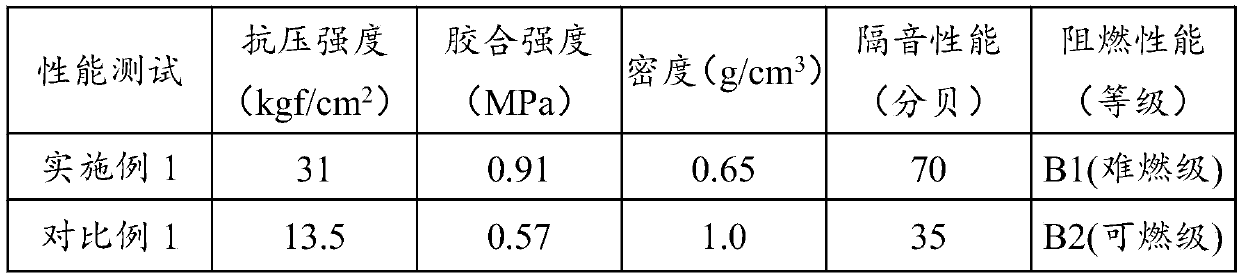

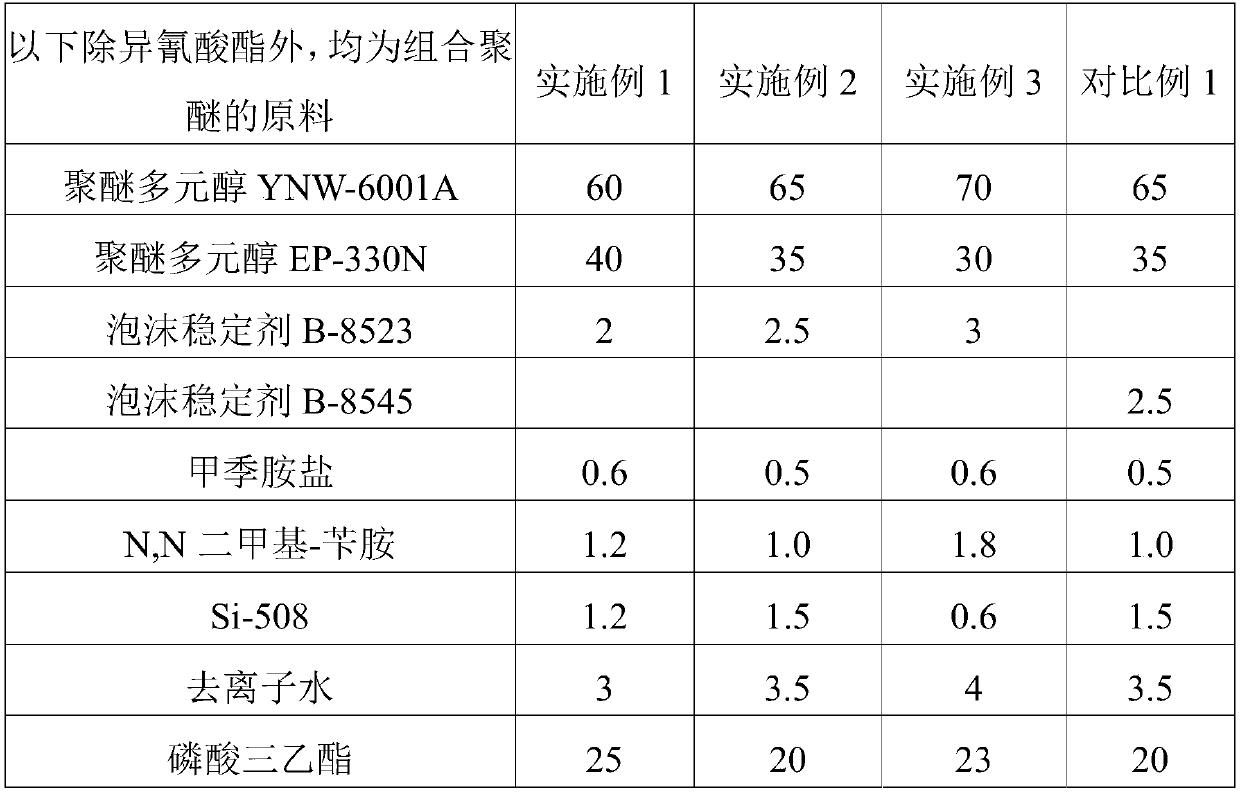

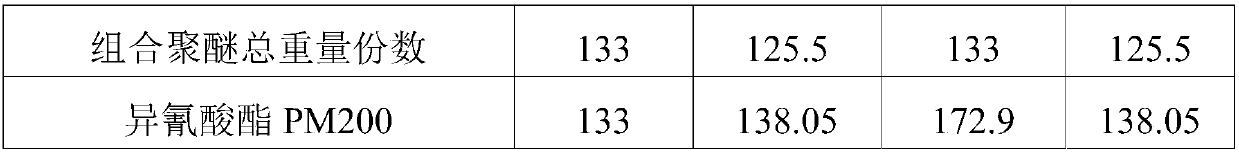

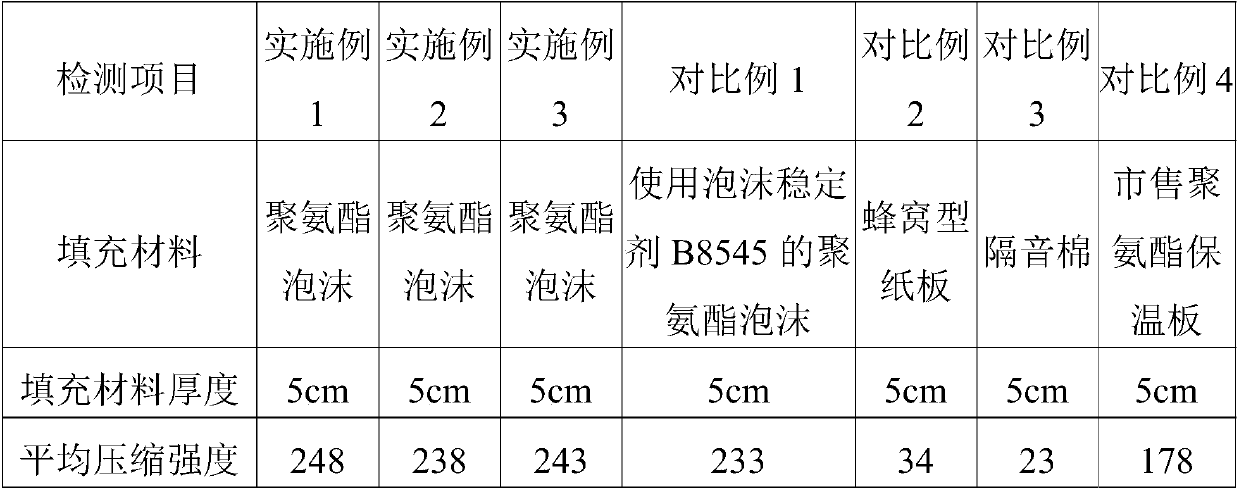

Combined polyether, polyurethane foam and its preparation method and application of soundproof door

The invention discloses a premixed polyether, and a polyurethane foam, a preparation method thereof and an application thereof in a sound insulation door. The premixed polyether comprises polyether polyol A, polyether polyol B, a silicone foam stabilizer, a catalyst, water and triethyl phosphate, and is characterized in that the silicone foam stabilizer is B-8523 silicone foam stabilizer produced by Evonik Degussa Specialty Chemicals (Shanghai) Co., Ltd. The polyurethane foam manufactured from the premixed polyether significantly improves a sound absorption coefficient, prepares the sound insulation door which can achieve good sound insulation effects, and thereby achieves the purpose of reducing noise pollution.

Owner:SHANGHAI DONGDA POLYURETHANE

Manufacturing method of porous weather-resistant abrasion-resistant sound-proof paint for external walls

InactiveCN110759707AGuaranteed protective effectGood weather resistanceCovering/liningsClimate change adaptationFiberMullite

The invention discloses porous weather-resistant abrasion-resistant sound-proof paint for external walls and a manufacturing method of the paint. The porous weather-resistant abrasion-resistant sound-proof paint for the external walls is composed of a three-layer structure, wherein the bottom layer is a ceramic structure which is formed by mixing montmorillonite and kaolin according to a mass ratio of (3-3.5):(8-10), mixing the obtained mixture and grid-like carbonized fibers and performing electric heating pulse and extends into wall body cement; the middle layer is a mullite-like porous ceramic structure obtained by mixing silicon dioxide micropowder, zircon powder, rutile powder, montmorillonite and kaolin according to a mass ratio of (5-6):(0.2-0.3):(0.1-0.2):(21-24.5):(56-70) and performing electric heating pulse treatment; and the surface layer is a silica gel membrane. The paint has the advantages of high water resistance, a high sound absorption coefficient, high weather resistance, self pore forming, environmental protection, no pollution, and good binding force with the walls.

Owner:SHANDONG GUANGYUN INTELLIGENT TECH CO LTD

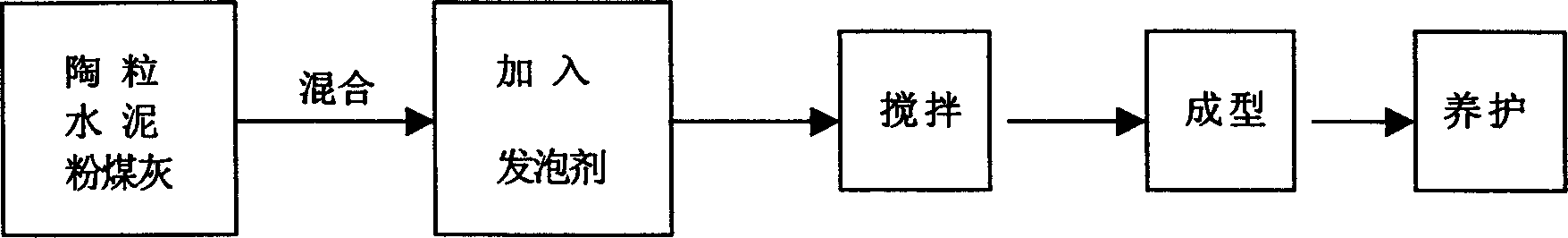

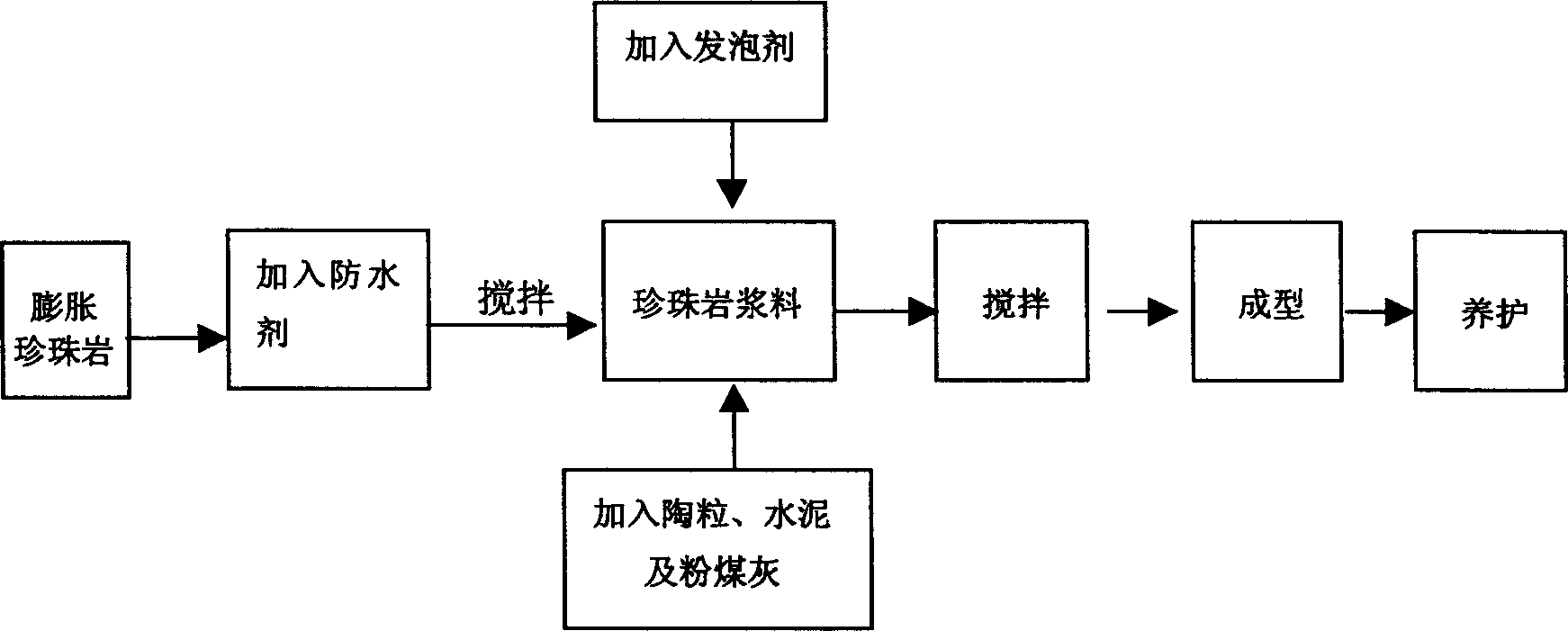

Sound-absorbing material for subway and its preparing process

InactiveCN1169739CFireproofWaterproofSolid waste managementSound proofingFoaming agentExpanded clay aggregate

A sound-absorbing material for subway is prepared from haydite (40-70%), cement (20-48%) flyash (0-10%) and foaming agent (1-2%) through diluting foaming agent with water, mixing the others, adding the deluted foaming agent to the mixture and shaping. Its advantages are broad audio band, high sound absorptivity, low volume weight, high strength, resisting fire and water, no toxicity, and low cost.

Owner:曾令可

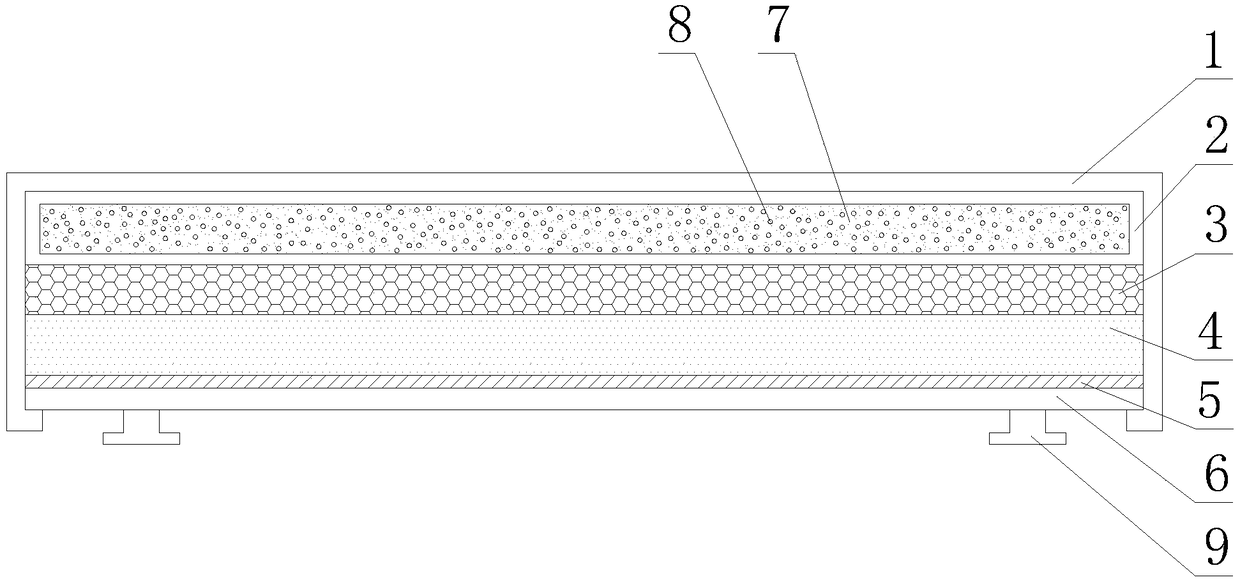

Aluminum alloy suspended ceiling plate capable of absorbing sound and radiation

InactiveCN109252609AIncrease refractionIncrease diffractionCeilingsSynthetic resin layered productsScattering attenuationSuspended particles

The invention discloses an aluminum alloy suspended ceiling plate capable of absorbing sound and radiation. The plate includes an aluminum alloy panel and an inner core structure; the inner core structure includes a first sound absorbing structure layer, a second sound absorbing structure layer, a third sound absorbing structure layer, a radiation absorbing structure layer and a bottom supportinglayer which are bonded with one another from outside to inside in sequence. A cavity is formed in the first sound absorbing structure layer and fully filled with a sound absorbing solution, and suspended particles are contained in the sound absorbing solution; the second sound absorbing structure layer is an alveolate layer, the third sound absorbing structure layer is a loose resin layer, and thebottom supporting layer is a stainless steel layer. The aluminum alloy suspended ceiling plate has the advantages that through multiple layers of sound absorbing structures, refraction, diffraction,scattering, reflection and the like of sound are increased, the efficiency of scattering and attenuating the sound is improved, and the sound absorption coefficient of the suspended ceiling plate is increased. Through a radiation absorbing structure layer which consists of multiple layers of metal screens and inserted lead glass, most of radiation can be absorbed, and influences caused by radiation to the human body are reduced. Moreover, the suspended ceiling plate is reasonable in structure, lightweight and convenient to install.

Owner:ANHUI CHENHANG ALUMINUM

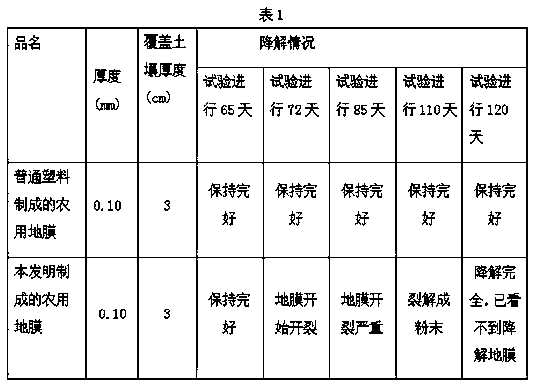

Method for preparing agricultural mulch film from sound-absorbing cotton leftover scraps used in vehicles

InactiveCN109370030AHighly Hydrophobic SubstancesIncrease filling volumePlant protective coveringsLow-density polyethyleneCerium

The invention belongs to the technical field of preparation of agricultural mulch films, in particular to a method for preparing agricultural mulch film for sound-absorbing cotton leftover scraps usedin vehicles. The preparation method comprises the steps: a step of pulverization of sound-absorbing cotton leftover scraps used in vehicles, a melting and granulating treatment step, a mixed treatment step of low-density polyethylene, polypropylene and liquid paraffin and a step of granulating the all materials through a screw extruder and blowing the materials into a mulch film with the thickness of 0.004mm to 0.1mm through a film blowing machine. Accordign to the degradable agriculture mulch film disclosed by the invention, the sound-absorbing cotton leftover scraps used in vehicles are used as one of the raw materials, and materials such as modified tapioca starch, a photosensitizer cerium stearate powder, a hindered phenolic antioxidant and a thermal degradation enhancer are added, sothat the degradable capability of the mulch film is improved, the degradation time of the mulch film is effectively controlled, the degradation effect is achieved, the production cost is reduced, andwhite pollution is reduced.

Owner:袁志平

A kind of glass fiber reinforced polyester composite filament and preparation method thereof

The invention relates to the field of chemical fiber manufacturing, in particular to a glass fiber reinforced polyester composite filament and a preparation method thereof. The composite filament is formed by mixing and compounding glass fiber and polyester. The fineness ratio of the glass fiber to the polyester is 1.8-3. The specific preparation method comprises the following steps: 1) pre-treating the glass fiber, 2) stranding, 3) false twisting, 4) sizing, 5) oiling and 6) winding molding to obtain a finished composite filament product. The glass fiber reinforced polyester composite filament with good performances can be obtained by the method.

Owner:ZHEJIANG HAONENG TECH CO LTD

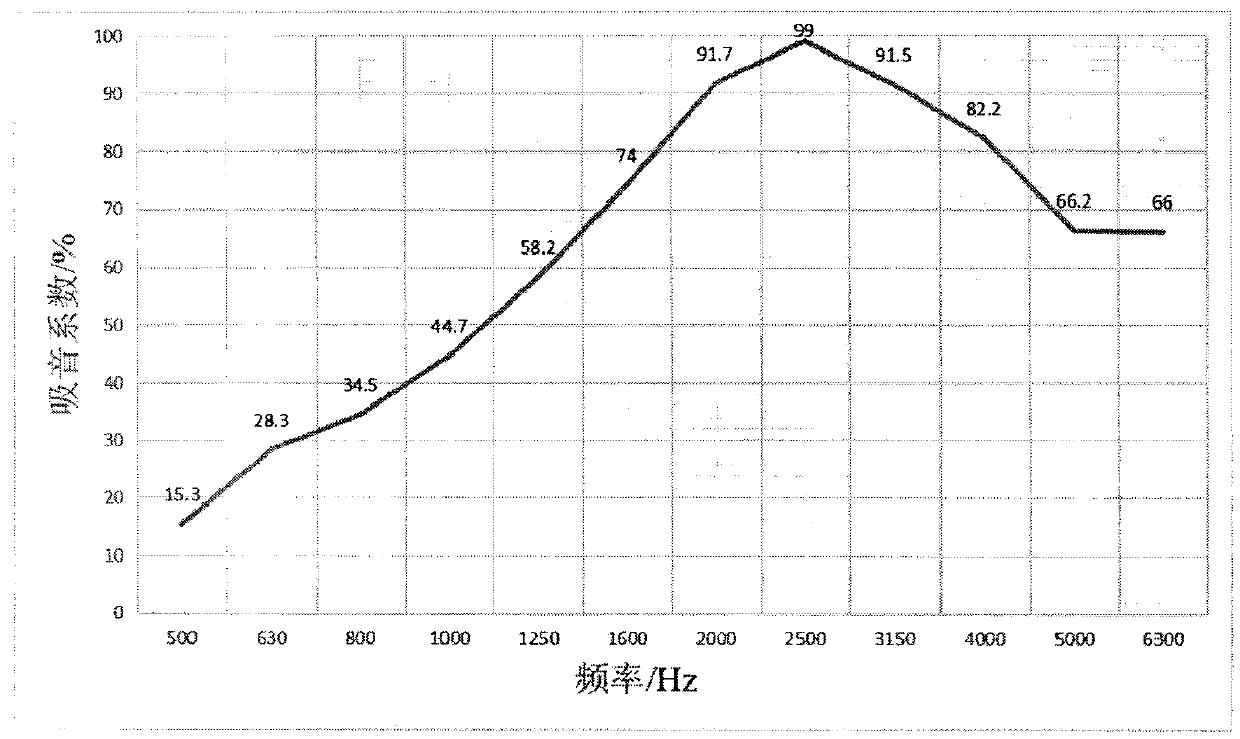

A kind of composite sound-absorbing material and preparation method thereof

The invention discloses a composite sound absorbing material, and a preparation method thereof. The composite sound absorbing material is prepared from, by weight, 88 to 100 parts of modified fly ash, 55 to 65 parts of organic bentonite, 50 to 65 parts of perlite, 55 to 60 parts of barite powder, 35 to 45 parts of aluminium oxide, 30 to 40 parts of antimonous oxide, 20 to 30 parts of stannous chloride, 20 to 30 parts of borax, and 10 to 15 parts of sodium silicate. The composite sound absorbing material is high in sound absorption coefficient, and wide in distribution frequency band; possesses excellent sound absorbing effect at low frequency (lower than 500Hz), medium frequency (500 to 2000Hz), and high frequency (higher than 2000Hz) zones, and wide application range; and also possesses excellent porosity, compressive yield strength, processing performance, and mechanical properties.

Owner:GUANGZHOU SOUNDBOX ACOUSTIC TECH

Nano-grade glass fibre cotton and mfg. technology and apparatus thereof

InactiveCN100360444CHigh sound absorption coefficientHigh-quality sound-absorbing materialGlass making apparatusGlass fiberFiber

Owner:HOHAI UNIV

Manufacturing method of environment-friendly saloon car sound insulating pad

ActiveCN102785370BMeet higher requirements for safety performanceSimple preparation processManufacturing technologyPalm fiber

The invention relates to a manufacturing method of a saloon car sound insulating pad, particularly relates to a novel manufacturing method of the saloon car sound insulating pad with an environment protection characteristic, and belongs to the manufacturing technology field of auto interior decoration. The manufacturing method comprises the steps: firstly, manufacturing a forming mold; secondly, using a palm fiber and a natural latex to blend so as to obtain a base material of the sound insulating pad; pressing and molding the base material of the sound insulating pad in a thermal forming mold to obtain a semi-finished product of the sound insolating pad; at last, putting a fabric in the mold and pressing and flattening the fabric and the semi-finished product, so as to obtain the environment-friendly saloon car sound insulating pad. According to the manufacturing method, the manufacturing process is simple and is similar to that of reconstituted cotton; only the innovation of the material gives a novel connotation to a traditional saloon car sound insulating pad; the sound absorption coefficient is greatly improved; at the same time, the improvement of the environment protection characteristic satisfies the higher demand of people on the safety performance of a passenger car; and the sound insulating pad is an environment-friendly product and achieves the goal of recycling on a certain technology basis.

Owner:WUXI GISSING AUTO PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com