Preparation process of ceramsite asphalt pavement material

A technology of asphalt pavement and preparation process, which is applied in the field of preparation of ceramsite asphalt pavement materials, which can solve problems such as aging, easy water seepage and cracks on the pavement, and achieve the effect of increasing interlayer aggregation, improving mechanical properties, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

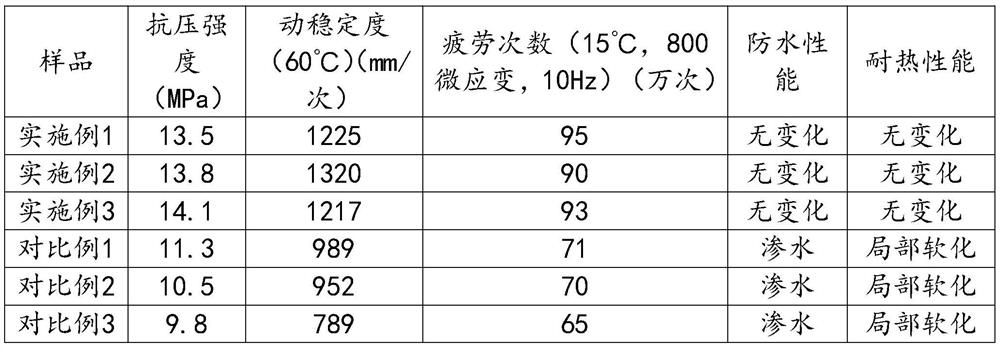

Examples

Embodiment 1

[0032] A preparation process of ceramsite asphalt pavement material, comprising the following steps:

[0033] The first step is to prepare the following raw materials by weight: 30 parts of asphalt, 1 part of modified nano filler, 10 parts of modified shale ceramsite, 5 parts of SBS modifier, 3 parts of basalt fiber, 2 parts of diatomite, rubber powder 5 parts, 0.3 parts of dispersant, 0.1 part of crosslinking agent, 0.1 part of antioxidant;

[0034]The second step is to add asphalt into the reaction kettle, control the reaction temperature to 180°C, add rubber powder and SBS modifier to the reaction kettle, and react for 2 hours at a speed of 1000r / min, then add dispersant, Cross-linking agent and antioxidant, under the condition of constant temperature and rotating speed, react for 20 minutes to obtain the basic pavement material;

[0035] Step 3: Add modified nano filler, modified shale ceramsite, basalt fiber and diatomaceous earth to the basic pavement material obtained ...

Embodiment 2

[0048] A preparation process of ceramsite asphalt pavement material, comprising the following steps:

[0049] The first step, prepare the following raw materials by weight, 35 parts of asphalt, 1 part of modified nano filler, 11 parts of modified shale ceramsite, 6 parts of SBS modifier, 4 parts of basalt fiber, 3 parts of diatomite, rubber powder 6 parts, 0.4 parts of dispersant, 0.2 parts of crosslinking agent, 0.2 parts of antioxidant;

[0050] The second step is to add asphalt into the reaction kettle, control the reaction temperature to 185°C, add rubber powder and SBS modifier to the reaction kettle, and react for 2.5 hours at a speed of 1200r / min, then add dispersant to the reaction kettle , cross-linking agent and antioxidant, under the condition of constant temperature and rotation speed, react for 23 minutes to obtain the basic pavement material;

[0051] Step 3: Add modified nano filler, modified shale ceramsite, basalt fiber and diatomaceous earth to the basic pav...

Embodiment 3

[0064] A preparation process of ceramsite asphalt pavement material, comprising the following steps:

[0065] The first step, prepare the following raw materials by weight, 40 parts of asphalt, 1.5 parts of modified nano filler, 12 parts of modified shale ceramsite, 8 parts of SBS modifier, 4 parts of basalt fiber, 3 parts of diatomite, rubber powder 8 parts, 0.4 parts of dispersant, 0.2 parts of crosslinking agent, 0.2 parts of antioxidant;

[0066] The second step is to add asphalt into the reaction kettle, control the reaction temperature to 190°C, add rubber powder and SBS modifier to the reaction kettle, and react for 3 hours at a speed of 1300r / min, then add dispersant, Cross-linking agent and antioxidant, under the condition of constant temperature and rotating speed, react for 25 minutes to obtain the basic pavement material;

[0067] Step 3: Add modified nano filler, modified shale ceramsite, basalt fiber and diatomaceous earth to the basic pavement material obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com