Combined polyether, polyurethane foam and its preparation method and application of soundproof door

A technology of polyurethane foam and combined polyether, which is applied in the application field of combined polyether, polyurethane foam and its preparation and sound insulation doors, which can solve the problems of low sound absorption coefficient, achieve good adhesion, good sound insulation effect, and increase openings rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1

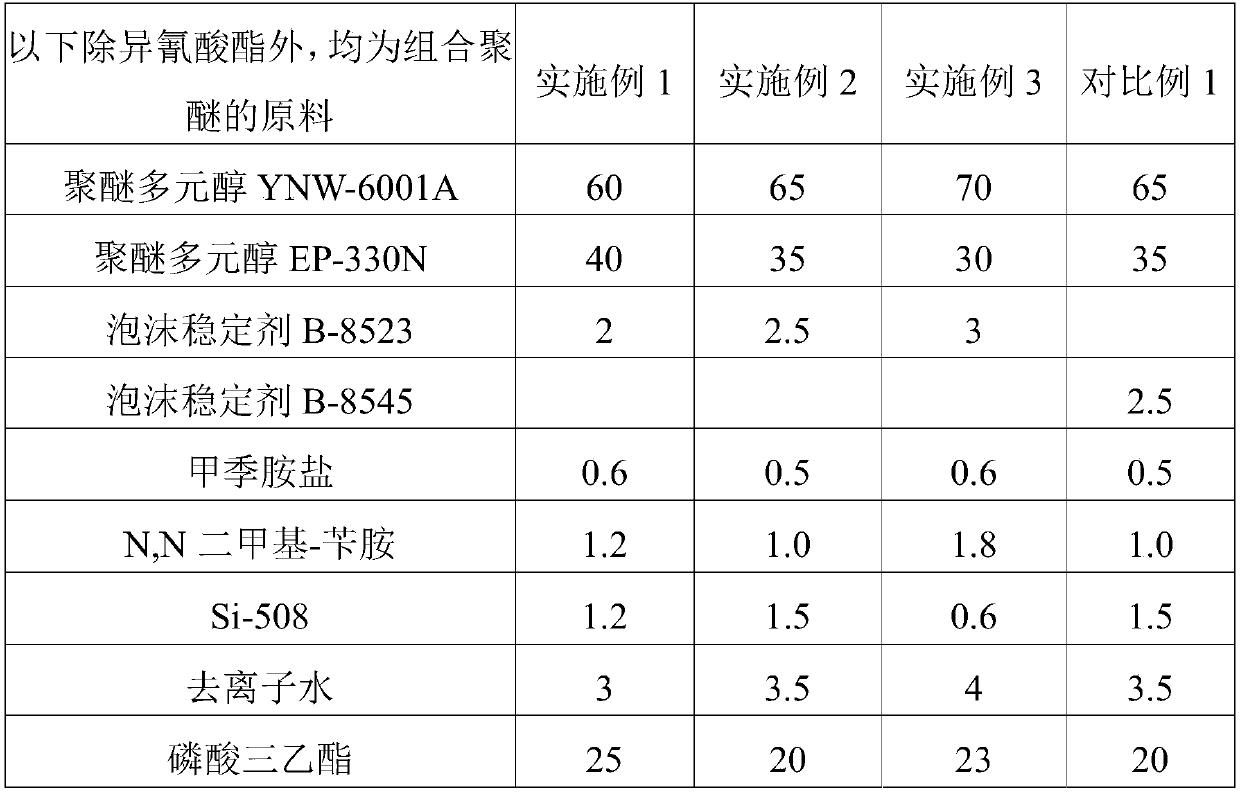

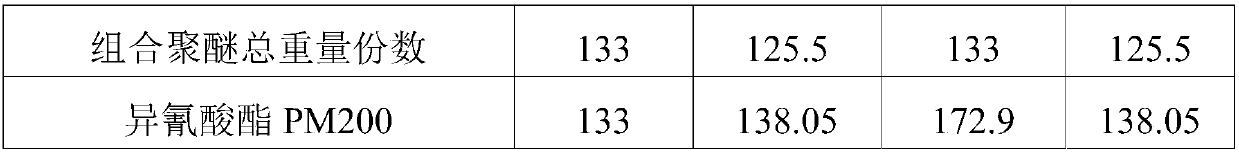

[0049] The parts by weight of the components combining polyether and isocyanate in Examples 1-3 are specifically shown in Table 1.

[0050] Table 1

[0051]

[0052]

[0053] (1) Preparation of combined polyether

[0054] Mix other components except isocyanate in a stainless steel mixing kettle for 45 minutes, and stir evenly.

[0055] (2) Preparation of polyurethane foam

[0056] Polyurethane foam can be prepared by mixing and reacting the combined polyether and isocyanate in proportion at 22°C.

Embodiment 4

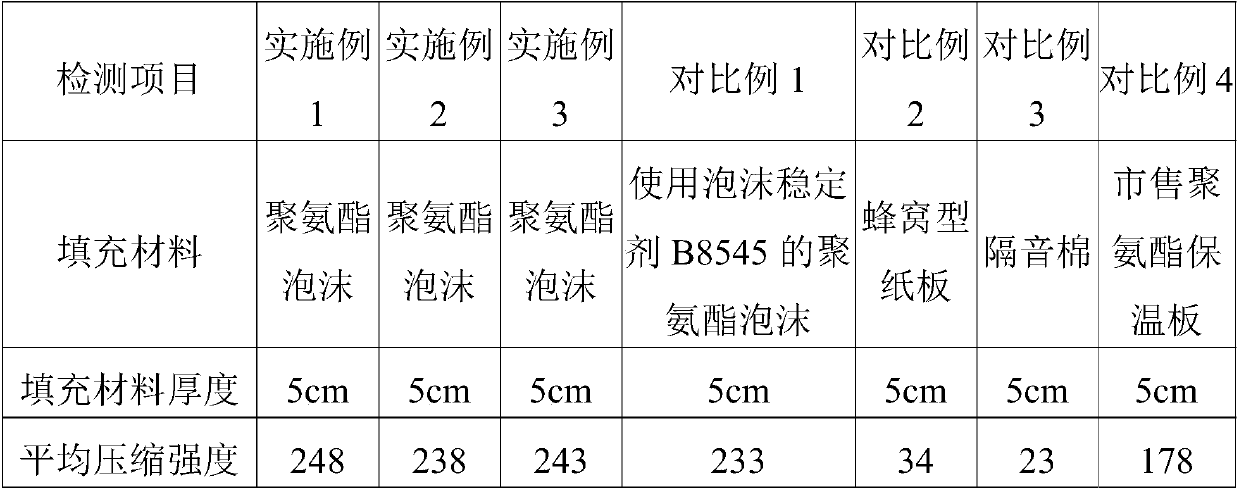

[0058] The polyurethane foam prepared in Examples 1-3 is directly injected into the door body to obtain a soundproof door filled with the polyurethane foam of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com