Melamine sponge

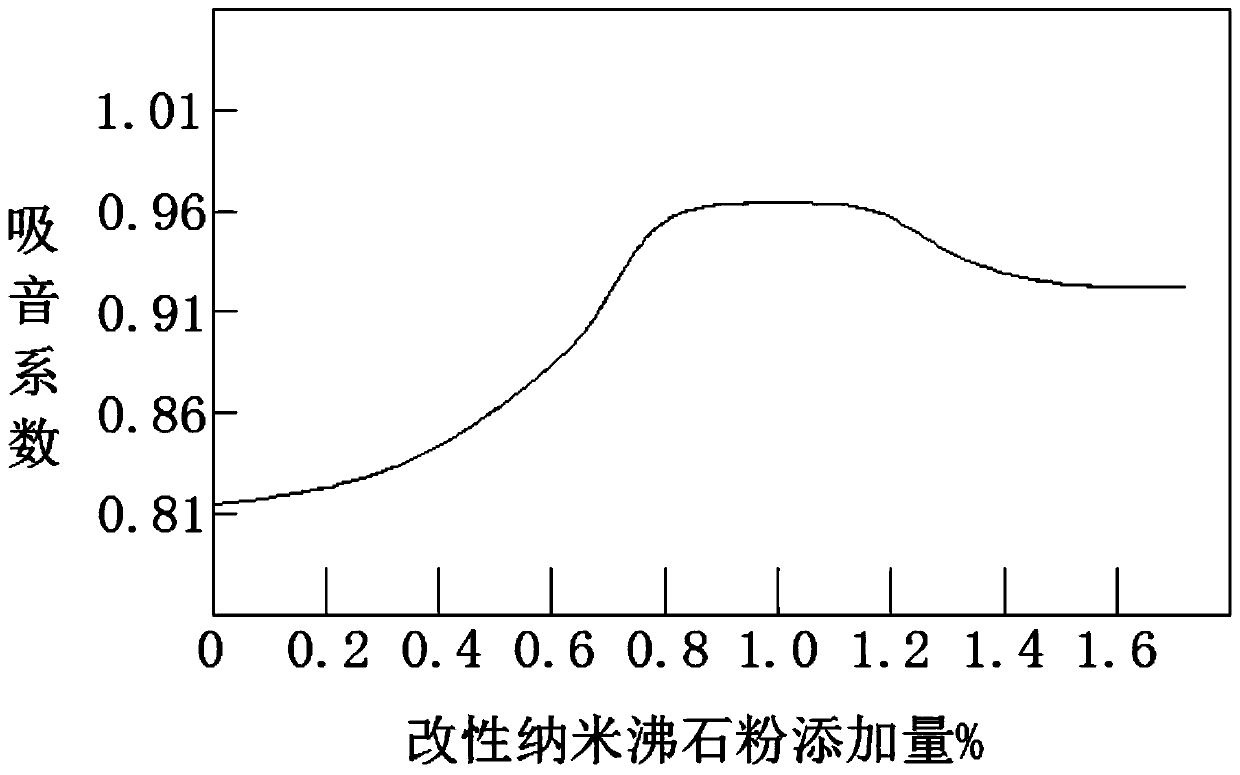

A technology of melamine sponge and ammonia water, which is applied in the field of melamine sponge, can solve the problems of unsatisfactory and general sound-absorbing effect, and achieve the effect of eliminating reflected waves and excellent sound-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of melamine sponge, comprises the following steps to make:

[0028] (1) Prepare ethanol / ammonia mixed solution:

[0029] Mix ethanol and ammonia water uniformly at a volume ratio of 1:4, then add stearate with 10% ethanol mass, and stir at 500 r / min for 35 minutes at 30°C to obtain the ethanol / ammonia water mixed solution ;

[0030] (2) Modified nano zeolite powder:

[0031] Disperse the nano zeolite powder evenly in deionized water to obtain a nano zeolite powder dispersion, then add it to the reaction kettle, heat to 68°C, stir at 500r / min for 10min, and then add the nano zeolite powder dispersion with a mass fraction of 6% polyoxyethylene alkylamine, continue to stir for 20 minutes, then add methyltrichlorosilane and ammonium persulfate, adjust the temperature to 79 ° C, keep stirring for 1 hour, then carry out suction filtration, and dry in a drying oven for 40 minutes to obtain The modified nano zeolite powder;

[0032] (3) Preparation of basic treatment...

Embodiment 2

[0046] A kind of melamine sponge, comprises the following steps to make:

[0047] (1) Prepare ethanol / ammonia mixed solution:

[0048] Mix ethanol and ammonia water uniformly at a volume ratio of 1:5, then add stearate with 11% ethanol mass, and stir at 500 r / min for 40 minutes at 33°C to obtain the ethanol / ammonia water mixed solution ;

[0049] (2) Modified nano zeolite powder:

[0050] Disperse the nano-zeolite powder evenly in deionized water to obtain a nano-zeolite powder dispersion, then add it to the reaction kettle, heat to 70°C, stir at a speed of 500r / min for 10min, and then add the nano-zeolite powder dispersion with a mass fraction of 7% polyoxyethylene alkylamine, continue to stir for 20 minutes, then add methyltrichlorosilane and ammonium persulfate, adjust the temperature to 86 ° C, keep stirring for 1.5 hours, then carry out suction filtration, and dry in a drying oven for 40 minutes to obtain The modified nano zeolite powder;

[0051] (3) Preparation of b...

Embodiment 3

[0065] A kind of melamine sponge, comprises the following steps to make:

[0066] (1) Prepare ethanol / ammonia mixed solution:

[0067] Mix ethanol and ammonia water uniformly at a volume ratio of 1:4.6, then add stearate with 10.3% ethanol mass, and stir at 500 r / min for 38 minutes at 32°C to obtain the ethanol / ammonia water mixed solution ;

[0068] (2) Modified nano zeolite powder:

[0069] Disperse the nano zeolite powder evenly in deionized water to obtain a nano zeolite powder dispersion, then add it to the reaction kettle, heat to 69°C, stir at 500r / min for 10min, then add the nano zeolite powder dispersion with a mass fraction of 6.4% polyoxyethylene alkylamine, continue to stir for 20 minutes, then add methyltrichlorosilane and ammonium persulfate, adjust the temperature to 81 ° C, keep stirring for 1.2 hours, then carry out suction filtration, and dry in a drying oven for 40 minutes to obtain The modified nano zeolite powder;

[0070] (3) Preparation of basic trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com