Method for preparing agricultural mulch film from sound-absorbing cotton leftover scraps used in vehicles

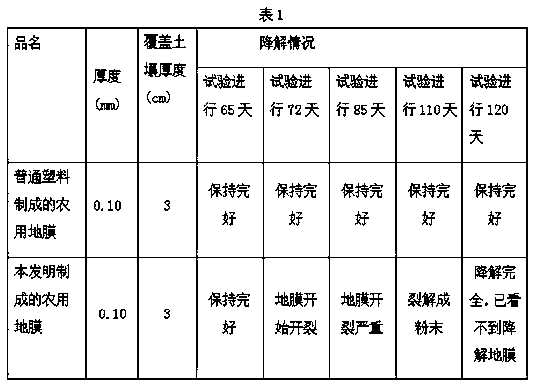

A technology for corner waste and agricultural mulch film, which is applied in botanical equipment and methods, applications, plant protection, etc., can solve the problems of difficult to control degradation time, difficult to be widely accepted by farmers, incomplete degradation, etc., to improve mechanical properties and degradation. Performance, apparent viscosity reduction, effect of particle size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing agricultural mulch film by using waste materials of sound-absorbing cotton for automobiles as raw materials, including the following steps:

[0027] (1) Coarsely pulverize the corner waste of sound-absorbing cotton for automobiles, and then melt and extrude them through a single-screw extruder. The extruded materials become plastic particles after being drawn, cooled, and pelletized, which are reserved for use; The waste of cotton corners is the waste of sound-absorbing cotton corners for cars containing PET and PP mixed fibers;

[0028] (2) Mix 50 parts of linear low-density polyethylene and 6 parts of polypropylene according to parts by weight to obtain a mixture, and then add liquid paraffin to the mixture according to the weight ratio of mixture: liquid paraffin of 300:0.8, and mix evenly; A;

[0029] (3) Add 40 parts of the plastic particles produced in step (1) to the mixture A in parts by weight; 35 parts of modified tapioca starch; 5 parts of mo...

Embodiment 2

[0035] A method for preparing agricultural mulch film by using waste materials of sound-absorbing cotton for automobiles as raw materials, including the following steps:

[0036] (1) Coarsely pulverize the corner waste of sound-absorbing cotton for automobiles, and then melt and extrude them through a single-screw extruder. The extruded materials become plastic particles after being drawn, cooled, and pelletized, which are reserved for use; The waste of cotton corners is the waste of sound-absorbing cotton corners for cars containing PET and PP mixed fibers;

[0037] (2) Mix 53 parts of linear low-density polyethylene and 8 parts of polypropylene according to parts by weight to obtain a mixture, and then add liquid paraffin to the mixture according to the weight ratio of mixture: liquid paraffin of 300:0.8 and mix well; A;

[0038] (3) Add 42 parts of the plastic particles produced in step (1) to the mixture A in parts by weight; 38 parts of modified tapioca starch; 8 parts of modif...

Embodiment 3

[0043] A method for preparing agricultural mulch film by using waste materials of sound-absorbing cotton for automobiles as raw materials, including the following steps:

[0044] (1) Coarsely pulverize the corner waste of sound-absorbing cotton for automobiles, and then melt and extrude them through a single-screw extruder. The extruded materials become plastic particles after being drawn, cooled, and pelletized, which are reserved for use; The waste of cotton corners is the waste of sound-absorbing cotton corners for cars containing PET and PP mixed fibers;

[0045] (2) Mix 55 parts of linear low-density polyethylene and 10 parts of polypropylene according to parts by weight to obtain a mixture, and then add liquid paraffin to the mixture according to the weight ratio of mixture: liquid paraffin of 300:0.8, and mix evenly; A;

[0046] (3) Add 45 parts of the plastic particles produced in step (1) to the mixture A in parts by weight; 40 parts of modified tapioca starch; 10 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com