A kind of composite sound-absorbing material and preparation method thereof

A technology of sound-absorbing materials and raw materials, which is applied in the field of composite sound-absorbing materials, can solve the problems of poor mechanical properties, poor moisture resistance, and low strength, and achieve good porosity and compressive yield strength, good processability and mechanical properties, and a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

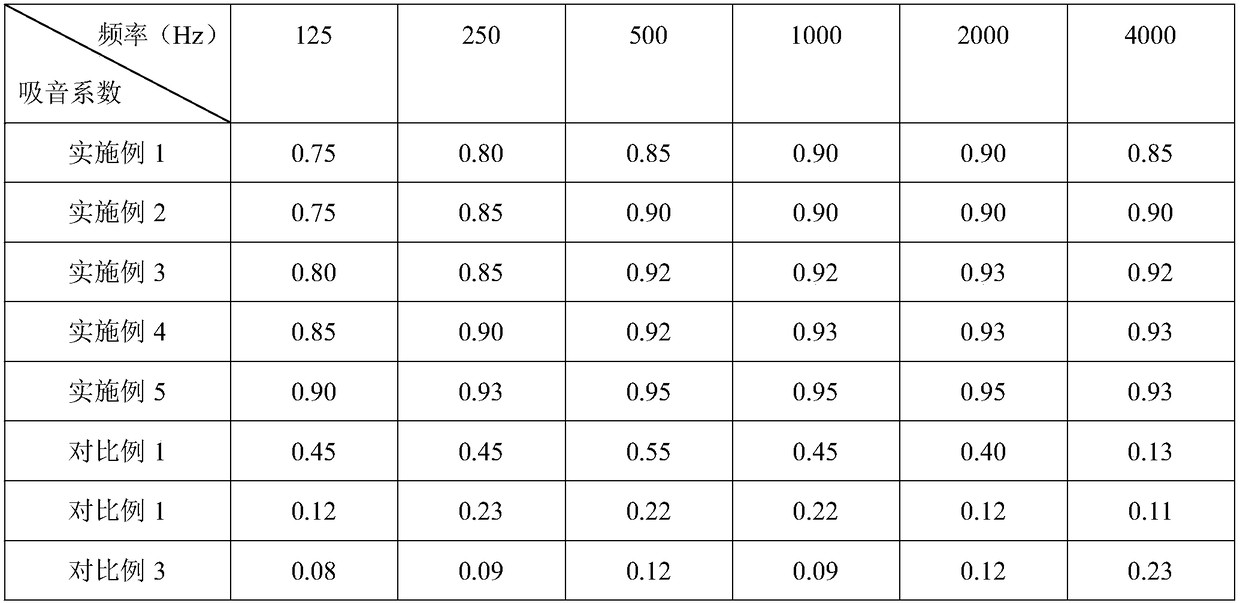

Examples

Embodiment 1

[0021] A composite sound-absorbing material of the present invention is made of the following raw materials: 88kg of modified fly ash, 55kg of organic bentonite, 50kg of perlite, 55kg of barite powder, 35kg of alumina, 30kg of antimony trioxide, and Tin 20kg, borax 20kg, sodium silicate 10kg; Wherein, modified fly ash is made by the following method: first soak 3 hours with the sodium hydroxide solution of mass concentration 12%, wash clean with deionized water, then use mass concentration Soak in 10% hydrochloric acid solution for 2 hours, wash with deionized water until neutral, dry, add 2% methyltriethoxysilane and 1% epoxidized triglyceride equivalent to the weight of fly ash, Stir at 1200r / min for 20 minutes, dry, pulverize and grind.

[0022] The above-mentioned preparation method of a composite sound-absorbing material comprises the steps of:

[0023] (1) Take by weighing the sodium silicate of formula quantity, prepare the sodium silicate solution with mass fraction 0...

Embodiment 2

[0028] A composite sound-absorbing material of the present invention is made of the following raw materials: 100kg of modified fly ash, 65kg of organic bentonite, 65kg of perlite, 60kg of barite powder, 45kg of alumina, 40kg of antimony trioxide, and Tin 30kg, borax 30kg, sodium silicate 15kg; Wherein, modified fly ash is made by the following method: first soak 4 hours with the sodium hydroxide solution of mass concentration 12%, wash clean with deionized water, then use mass concentration Soak in 10% hydrochloric acid solution for 3 hours, wash with deionized water until neutral, dry, add 3% methyltriethoxysilane and 2% epoxidized triglyceride equivalent to the weight of fly ash, Stir at 1500r / min for 30 minutes, dry, pulverize and grind.

[0029] The above-mentioned preparation method of a composite sound-absorbing material comprises the steps of:

[0030] (1) Take the sodium silicate of formula quantity, prepare with water the sodium silicate solution of mass fraction 1.5...

Embodiment 3

[0035] A composite sound-absorbing material of the present invention is made of the following raw materials: 90kg of modified fly ash, 58kg of organic bentonite, 52kg of perlite, 56kg of barite powder, 38kg of alumina, 32kg of antimony trioxide, and Tin 23kg, borax 22kg, sodium silicate 11kg; Wherein, the modified fly ash is made by the following method: first soak 3 hours with the sodium hydroxide solution of mass concentration 12%, wash clean with deionized water, then use mass concentration Soak in 10% hydrochloric acid solution for 3 hours, wash with deionized water until neutral, dry, add 2% methyltriethoxysilane and 2% epoxidized triglyceride equivalent to the weight of fly ash, Stir at 1300r / min for 20 minutes, dry, pulverize and grind.

[0036] The above-mentioned preparation method of a composite sound-absorbing material comprises the steps of:

[0037] (1) Take the sodium silicate of formula quantity, prepare with water the sodium silicate solution of mass fraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com