Three-component sound-absorbing cotton and preparation method thereof

A sound-absorbing cotton, three-component technology, applied in the field of sound-absorbing materials, can solve the problem of low sound-absorbing coefficient, achieve the effect of improving the sound-absorbing coefficient, improving the sound-absorbing coefficient of the material, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

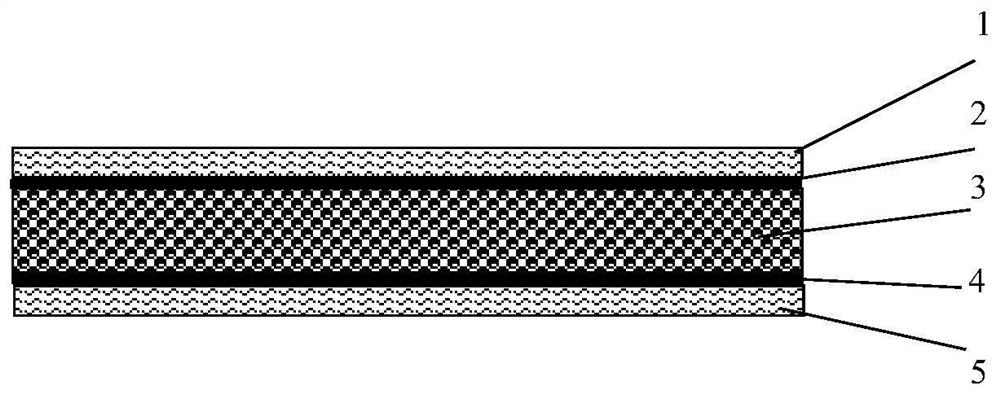

[0035] Such as figure 1 As shown, the three-component sound-absorbing cotton of this embodiment includes an upper surface layer 1, a first adhesive layer 2, an intermediate layer 3, a second adhesive layer 4, and a lower surface layer 5, which are stacked sequentially from top to bottom. 3 is made of polyurethane porous foam material, the upper surface layer 1 and the lower surface layer 5 are both made of mixed fibers of polyethylene terephthalate fiber and polypropylene fiber, the first adhesive layer 2 and the The second adhesive layer 4 is made of adhesive.

[0036] Wherein, the thickness of the upper surface layer 1 and the lower surface layer 5 is the same, both are 3mm; the thickness of the middle layer 3 is 9mm, and the thickness of the first adhesive layer 2 and the second adhesive layer 4 are both 0.1mm.

[0037] The open porosity of described polyurethane porous foam material is 50%, and density is 0.03g / cm 3 , cell diameter ≤ 5mm.

[0038] In the mixed fiber of...

Embodiment 2

[0051] Such as figure 1 As shown, the three-component sound-absorbing cotton of this embodiment includes an upper surface layer 1, a first adhesive layer 2, an intermediate layer 3, a second adhesive layer 4, and a lower surface layer 5, which are stacked sequentially from top to bottom. 3 is made of polyurethane porous foam material, the upper surface layer 1 and the lower surface layer 5 are both made of mixed fibers of polyethylene terephthalate fiber and polypropylene fiber, the first adhesive layer 2 and the The second adhesive layer 4 is made of adhesive.

[0052] Wherein, the thickness of the upper surface layer 1 and the lower surface layer 5 is the same, both are 5mm; the thickness of the middle layer 3 is 15mm, and the thickness of the first adhesive layer 2 and the second adhesive layer 4 are both 0.5mm.

[0053] The open porosity of described polyurethane porous foam material is 20%, and density is 0.001g / cm 3 , cell diameter ≤ 5mm.

[0054] In the mixed fiber ...

Embodiment 3

[0065] Such as figure 1 As shown, the three-component sound-absorbing cotton of this embodiment includes an upper surface layer 1, a first adhesive layer 2, an intermediate layer 3, a second adhesive layer 4, and a lower surface layer 5, which are stacked sequentially from top to bottom. 3 is made of polyurethane porous foam material, the upper surface layer 1 and the lower surface layer 5 are both made of mixed fibers of polyethylene terephthalate fiber and polypropylene fiber, the first adhesive layer 2 and the The second adhesive layer 4 is made of adhesive.

[0066] Wherein, the thickness of the upper surface layer 1 and the lower surface layer 5 is the same, both are 1.5mm; the thickness of the middle layer 3 is 3mm, and the thickness of the first adhesive layer 2 and the second adhesive layer 4 are equal. 0.3mm.

[0067] The open porosity of described polyurethane porous foam material is 80%, and density is 0.06g / cm 3 , cell diameter ≤ 5mm.

[0068] In the mixed fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com