Sound-absorbing material for subway and its preparing process

A technology for sound-absorbing materials and subways, applied in the field of sound-absorbing materials, can solve the problems of low cost and high sound-absorbing coefficient, and achieve the effects of low bulk density, high sound-absorbing coefficient and good sound-absorbing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

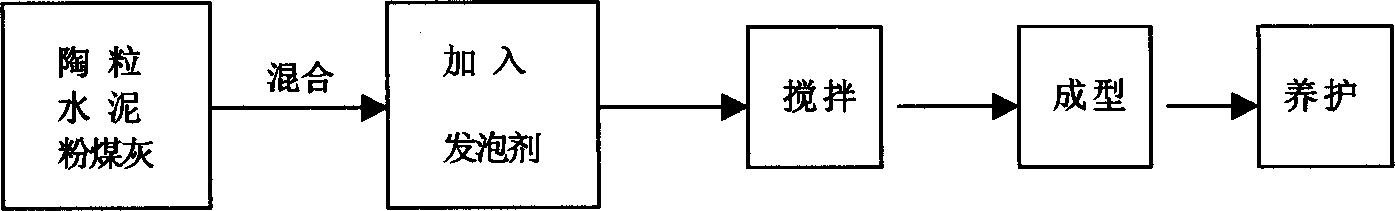

[0016] figure 1 Show the technological process of the subway sound-absorbing material preparation method of the present invention, by figure 1 Visible, the technological process of this method comprises the following operation steps: (1) ceramsite, cement and fly ash in the base material are mixed; (2) dilute foaming agent with water, add the mixture of ceramsite, cement and fly ash (3) Forming; (4) Curing. The composition of the base material of the subway sound-absorbing material is: ceramsite: 70%; alunite expansion cement: 20%; fly ash: 10%; foaming agent: 2%. The subway sound-absorbing material can be prepared according to the above process, and its performance test results are shown in Table 1.

[0017] Wet bulk density (kg / m 3 )

Embodiment 2

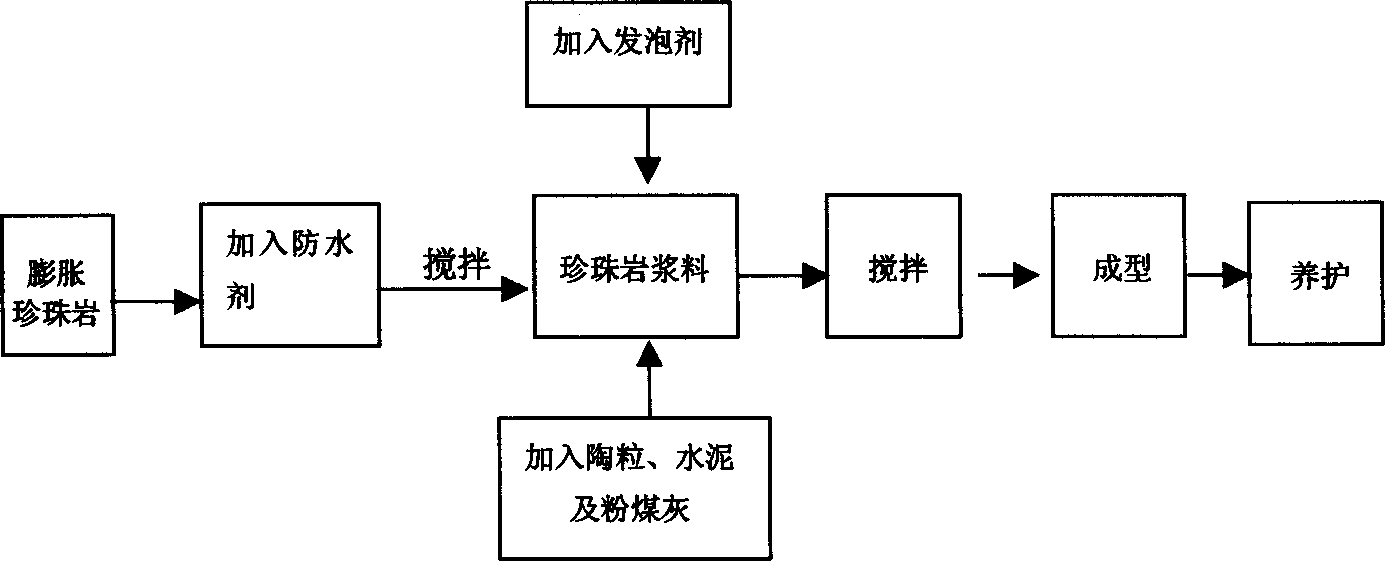

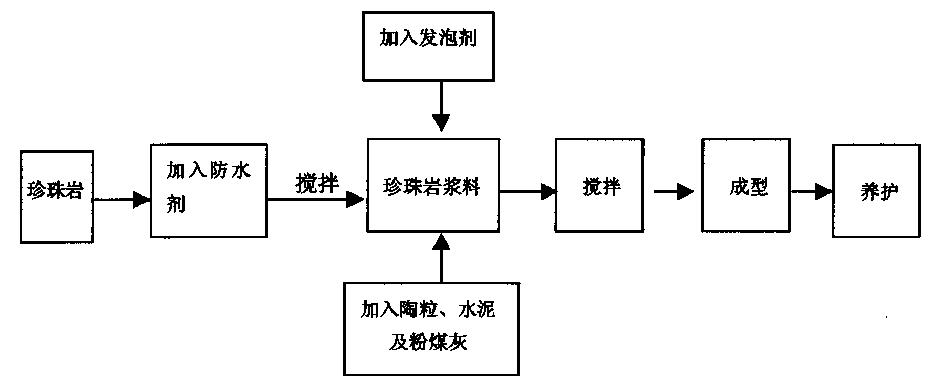

[0019] figure 2 Another process flow of the method for preparing the subway sound-absorbing material of the present invention is shown, by figure 2 Visible, the technological process of this method comprises the following operation steps: (1) add waterproofing agent to expanded perlite, then stir and mix to obtain perlite slurry; (2) mix perlite slurry with ceramsite, cement and fly ash; ( 3) Dilute the foaming agent with water, add to the mixture in the above steps and stir to mix; (4) Forming; (5) Curing. The composition of the base material of the subway sound-absorbing material is: ceramsite: 47%; alunite expanded cement: 28%; polymer cement: 10%; lightweight cement: 10%; expanded perlite: 5%; foaming agent: 1%; waterproofing agent: 2%. according to figure 2 The technological process shown is prepared to obtain the local subway sound-absorbing material, and its performance test results are shown in Table 2.

[0020] Wet bulk density (kg / m3)

[0021] As can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sound absorption coefficient | aaaaa | aaaaa |

| Sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com