Sound-absorbing rigid polyurethane foam composite material for vehicles

A polyurethane rigid foam combination material and vehicle-use technology, applied in the field of polyurethane, can solve the problems of limited application range, poor foam mechanical properties, and low sound absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

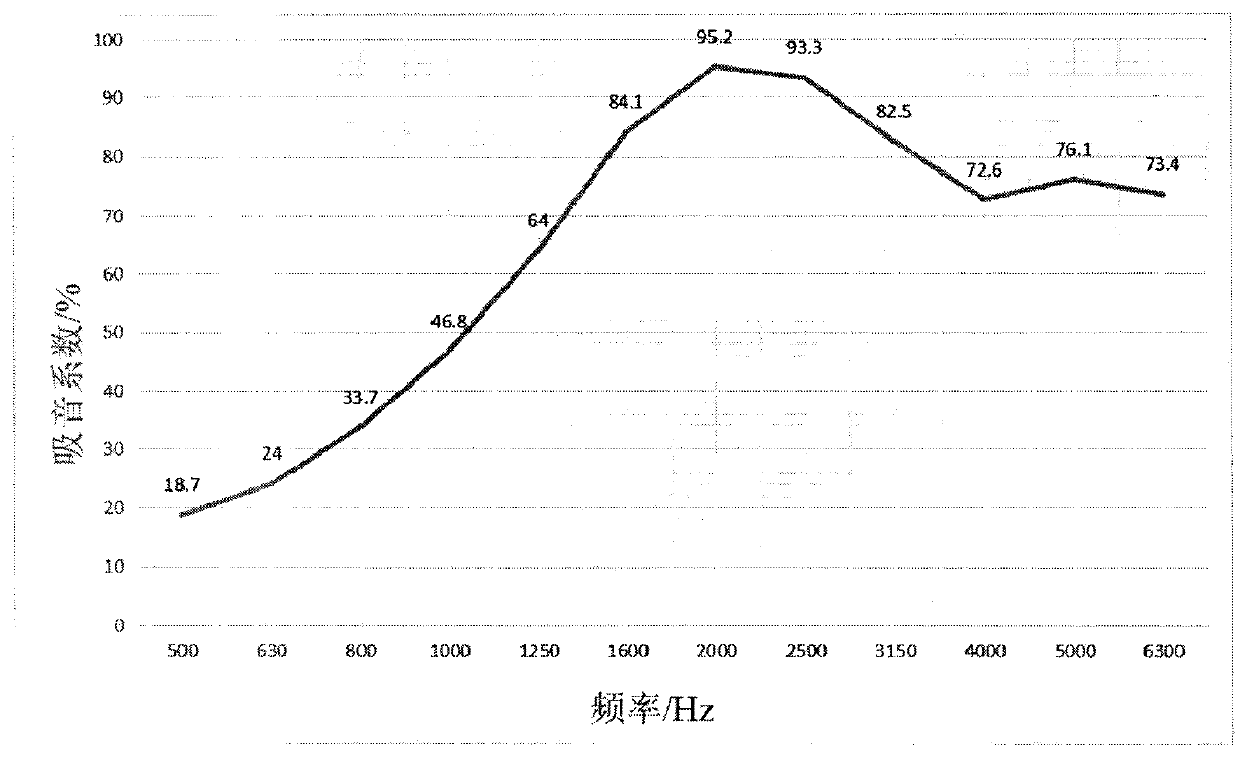

Embodiment 1

[0037] Preparation of component A:

[0038] Accurately measure 58 parts of polyether polyol A (functionality 3, molecular weight 4700), 16 parts of polyester polyol (2 functionality, molecular weight 300), 15 parts of polyether polyol B (functionality 3, molecular weight 500) , 1.5 parts of chain extender ethylene glycol, 3 parts of diethylene glycol, catalyst tetramethyliminodipropylamine Jeffcat Z-130 (U.S. Huntsman Company) 0.3 parts, N, N, N'-trimethyl- N'-hydroxyethyl bisaminoethyl ether Jeffcat Z-10 (U.S. Huntsman company) 0.2 part, pentamethyldiethylenetriamine Polycat 5 (Evonik Industrial Group) 0.15 part, surfactant Tegostab B 8870 (win 0.85 parts of Evonik Industrial Group), 2 parts of Ortegol 501 (Evonik Industrial Group), and 3 parts of water were put into the reaction kettle, stirred and mixed for 2 hours, and sealed and packaged.

[0039] Component B: polymethylene polyphenyl polyisocyanate

[0040] The materials of components A and B are mixed and reacted acco...

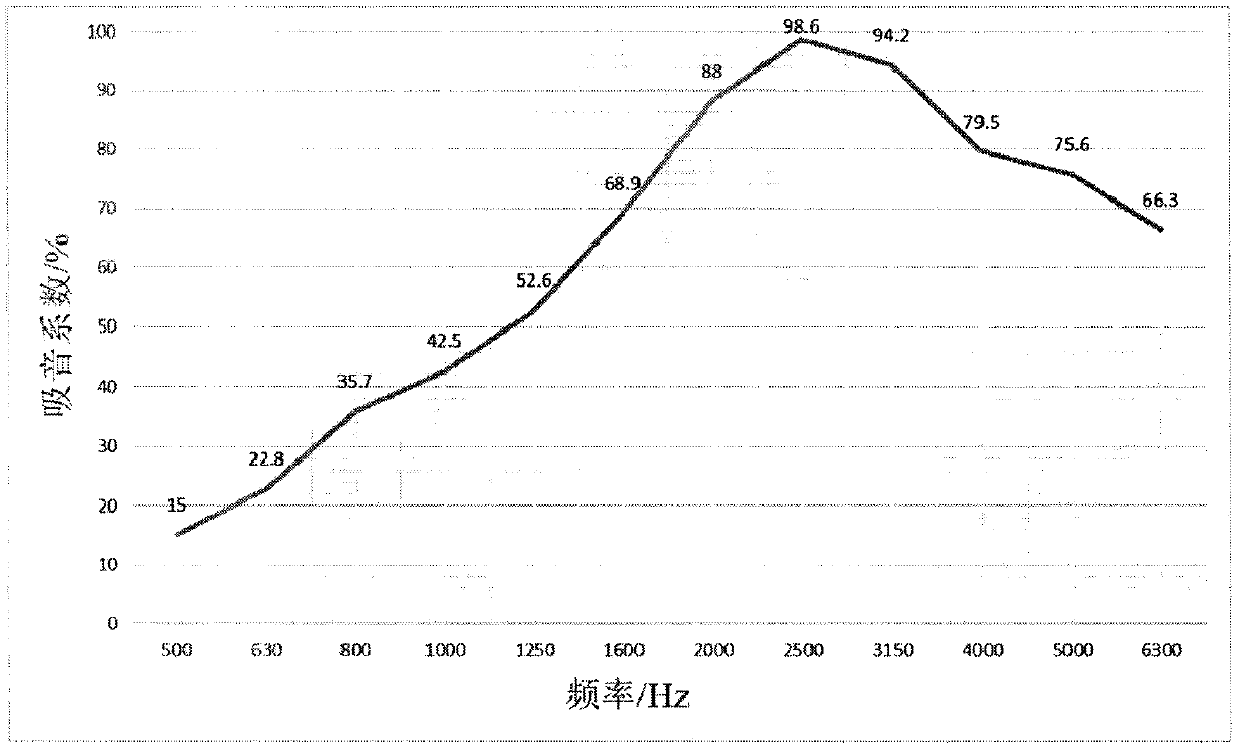

Embodiment 2

[0042] Preparation of component A:

[0043] Accurately measure 60 parts of polyether polyol A (functionality 3, molecular weight 6000), 20 parts of polyester polyol (2 functionality, molecular weight 660), 10 parts of polyether polyol B (functionality 4, molecular weight 700) , chain extender glycerol 4.5 parts, catalyst N-methyl-N-(dimethylaminopropyl) aminoethanol Polycat 17 (Evonik Industrial Group) 0.5 parts, N, N-bis(dimethylaminopropyl) ) Isopropanolamine Jeffcat ZR-50 (U.S. Huntsman Company) 0.5 part, catalyst bis(2-dimethylaminoethyl) ether Polycat BL-17 (Evonik Industrial Group) 0.1 part, surfactant AK-8805 ( Jiangsu Meisid Chemical Co., Ltd.) 0.15 parts, surfactant AK-6680 (Jiangsu Meisid Chemical Co., Ltd.) 0.75 parts, surfactant AK-9905 (Jiangsu Meisid Chemical Co., Ltd.) 1.5 parts, Put 2 parts of water into the reaction kettle, stir and mix for 2 hours, take out the material after sampling and testing, and seal the package;

[0044] Component B: polymethylene po...

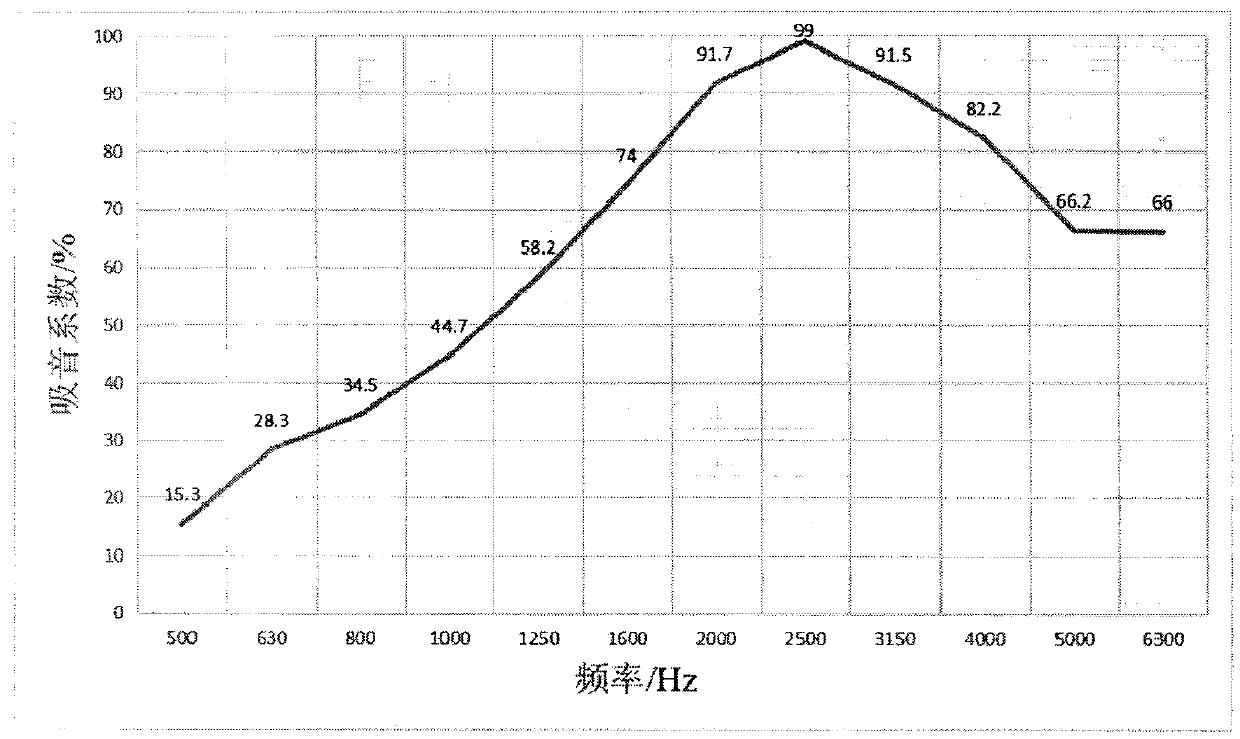

Embodiment 3

[0047] Preparation of component A:

[0048] Accurately measure 46 parts of polyether polyol A (functionality 3, molecular weight 3000), 23.5 parts of polyester polyol (2 functionality, molecular weight 2000), 18 parts of polyether polyol B (functionality 3, molecular weight 300) , 7 parts of chain extender dipropylene glycol, catalyst N, N-dimethylaminoethyl-N'-methylaminoethanol Jeffcat ZR-110 (U.S. Huntsman Company) 0.2 parts, 2,2-bismorpholino diethyl Base ether Dabco DMDEE (Evonik Industrial Group Company) 0.5 part, surfactant L-580 (Momentive) 0.7 part, Tegostab B 8523 (Evonik Industrial Group Company) 0.2 part, water 3.9 parts, put into the reaction kettle, stir and mix 2 hours, after sampling and testing, discharge and seal the package.

[0049] Component B: polymethylene polyphenyl polyisocyanate

[0050] The materials of components A and B are mixed and reacted according to the weight ratio of A:B=100:95 to prepare foam, and the quality of the product is tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com