Dense-graded asphalt concrete with continuous skid-resistant and noise-reduction functions

An asphalt concrete and dense grading technology, applied in the field of dense grading asphalt concrete, can solve problems such as the attenuation of anti-skid and noise reduction performance, and achieve the effects of good bearing capacity and durability, good noise reduction effect, and good bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

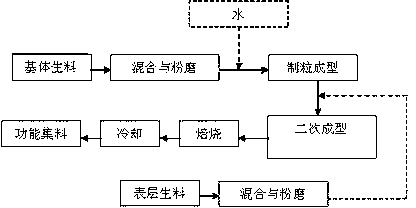

Method used

Image

Examples

Embodiment 1

[0050] (1) Screening of mineral materials: According to "Technical Specifications for Construction of Highway Asphalt Pavement (JTG F40-2004)", various mineral materials are screened. The asphalt is SBS I-D modified asphalt, the functional aggregate prepared in Example 11 is used as the coarse aggregate, machine-made sand and stone chips are used as the fine aggregate, and mineral powder is used as the filler.

[0051](2) Determination of mineral material density: According to "Technical Specifications for Highway Asphalt Pavement Construction (JTG F40-2004)", the apparent relative density and gross volume relative density of various mineral materials were measured.

[0052] (3) Carry out mineral material gradation design according to "Technical Specifications for Highway Asphalt Pavement Construction (JTG F40-2004)", and use the resulting gradation ratio as the volume mix ratio of various mineral materials, and then according to the following formula, each The volume mix rati...

Embodiment 2

[0061] Using the functional aggregate prepared in Example 12, the mineral aggregates were graded according to the densely graded asphalt concrete AC-10, and the rest were the same as in Example 1. The mineral aggregate volume grading ratio and the optimum asphalt ratio are shown in Table 6.

[0062] Its freeze-thaw splitting strength ratio, water immersion residual stability and durability test (including the comparison of anti-skid performance and noise reduction performance before and after use) are listed in Table 7.

Embodiment 3

[0064] Using the functional aggregate prepared in Example 13, the mineral aggregates were graded according to the densely graded asphalt concrete AC-16, and the rest were the same as in Example 1. The mineral aggregate volume grading ratio and the optimal asphalt ratio are shown in Table 6.

[0065] Its freeze-thaw splitting strength ratio, water immersion residual stability and durability test (including the comparison of anti-skid performance and noise reduction performance before and after use) are listed in Table 7.

[0066] Table 6 AC-10, AC-13, AC-16 densely graded asphalt concrete volume ratio

[0067]

[0068]

[0069] * The OGFC-13 type asphalt mixture of comparative example 1 adopts high-viscosity modified asphalt, and the AC-13 type asphalt concrete of comparative example 2 adopts SBS modified asphalt, ** The data in brackets is the nominal size range of coarse aggregate.

[0070] Table 7 Performance comparison of asphalt concrete with different grades

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com