Preparation method for high-resistance inorganic-organic composite modified acrylic epoxy ester resin

An acrylic epoxy ester and inorganic composite technology, applied in the direction of coating, can solve problems such as gloss and resistance effect, and achieve the effect of improving dryness

Active Publication Date: 2015-07-01

BEIJING JINHWEILI APPLIED CHEM PROD

View PDF7 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method uses emulsion polymerization to coat nanoparticles, but the performance limitations of the emulsion still exist, such as the impact of a large amount of emulsifier on gloss, resistance, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

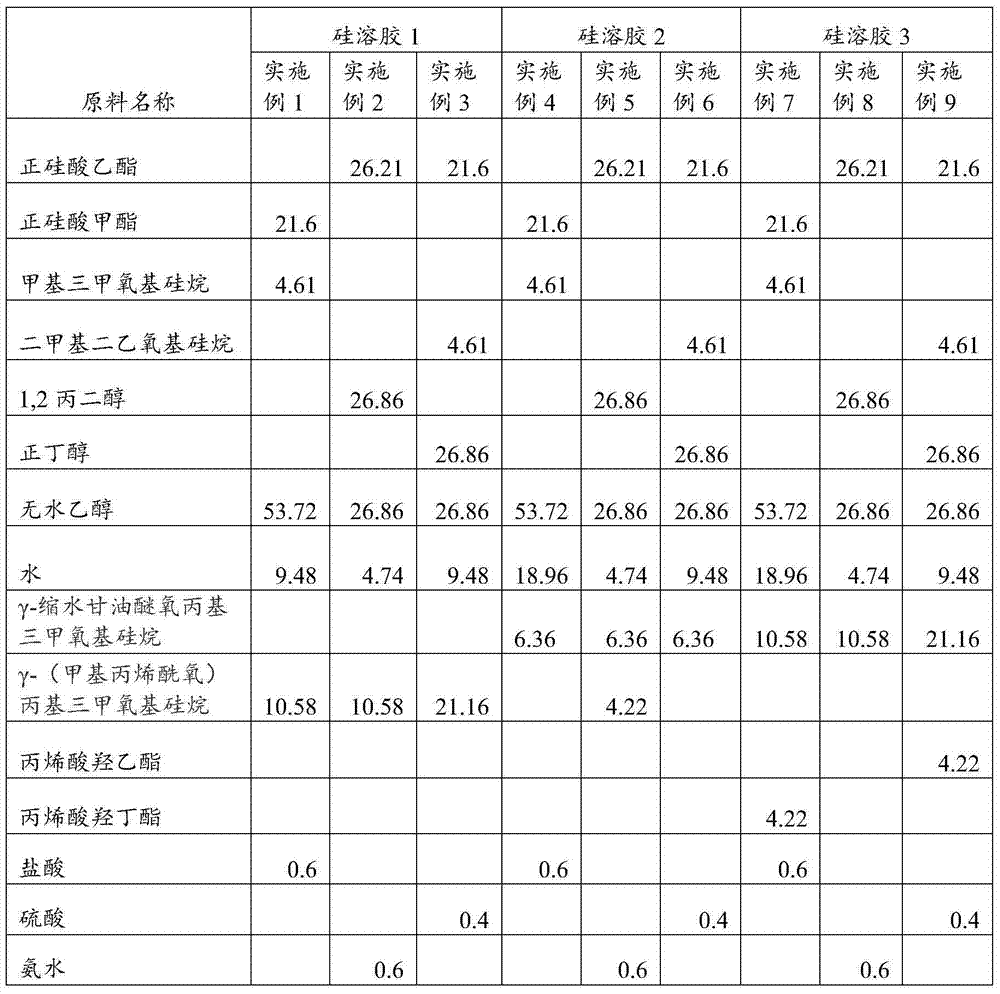

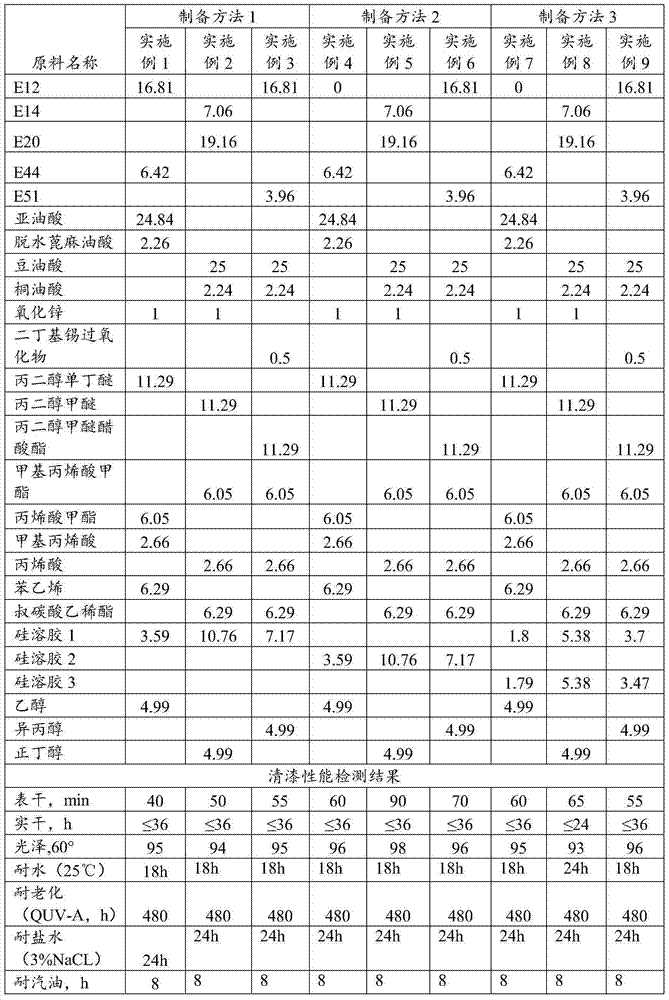

[0065] Table 2 Resin implementation formula table

[0066]

[0067] From the above results, it can be seen that silica sol 1 has a higher luster; the resin introduced by silica sol 2 has the best surface-drying performance; the introduction of silica sol 1 and silica sol 3 will affect the gloss, but the dryness and tolerance of the resin are significantly improved.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the field of water-based paints, and discloses a high-resistance inorganic-organic composite modified acrylic epoxy ester resin. The high-resistance inorganic-organic composite modified acrylic epoxy ester resin is synthesised from the following raw materials in parts by weight: 30-70 parts of epoxy ester, 5-50 parts of acrylic monomers and 5-25 parts of silica gel, wherein the epoxy ester is prepared by carrying out a catalytic reaction on 40-70 parts of epoxy resin and 20-60 parts of unsaturated fatty acid; the acrylic monomers comprise 20-60 parts of vinyl monomers and 40-70 parts of acrylic acid monomers; the silica gel is prepared by reacting 10-50 parts of an organic silicon intermediate, 5-50 parts of a silane coupling agent, 20-70 parts of a cosolvent, 0.2-5 parts of a pH value regulator and 5-15 parts of water; the nanoscale silica gel is capable of improving the resistance and dryness of a paint film; secondary crosslinking is formed along with the changes of a pH value, thus increasing the crosslinking density after film formation; the structure taking the nanoscale silica gel as a core and the organic resin as a shell is capable of improving the stability of silicon hydroxyl; the water-based epoxy ester resin is capable of reducing a VOC content.

Description

technical field [0001] The invention relates to a preparation method of a highly resistant organic-inorganic composite modified waterborne epoxy acrylate resin, which belongs to the field of waterborne industrial coatings. Background technique [0002] Alkyd resin has the characteristics of dryness, gloss, flexibility, good adhesion, good wetting performance to pigments, excellent construction performance, full coating and excellent decoration. However, its coating film is soft, and its water resistance and alkali resistance are not good. Due to the presence of a large number of ester bonds, the stability of waterborne alkyd resins is often problematic. A large amount of modification techniques have been developed at present, such as a kind of epoxy-modified water-based alkyd resin and its preparation method in patent CN101838389A. Improved adhesion and corrosion resistance, but did not solve the problem of alkyd resin hydrolysis stability; patent CN102391439A introduces s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F290/06C08F212/08C08F220/14C08F220/06C08F218/00C08F2/44C08K9/06C08K3/36C09D151/08C09D7/12

Inventor 陈明秦文王英

Owner BEIJING JINHWEILI APPLIED CHEM PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com