Production and processing equipment and method for high-glossiness draw-textured yarn

A technology of stretched textured yarn and high gloss, applied in the field of spinning, can solve the problems of lack of softness and beauty, poor comfort and flexibility, dull gloss, etc., to prevent the reaction test from being too long, avoid pollution, The effect of reducing the interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

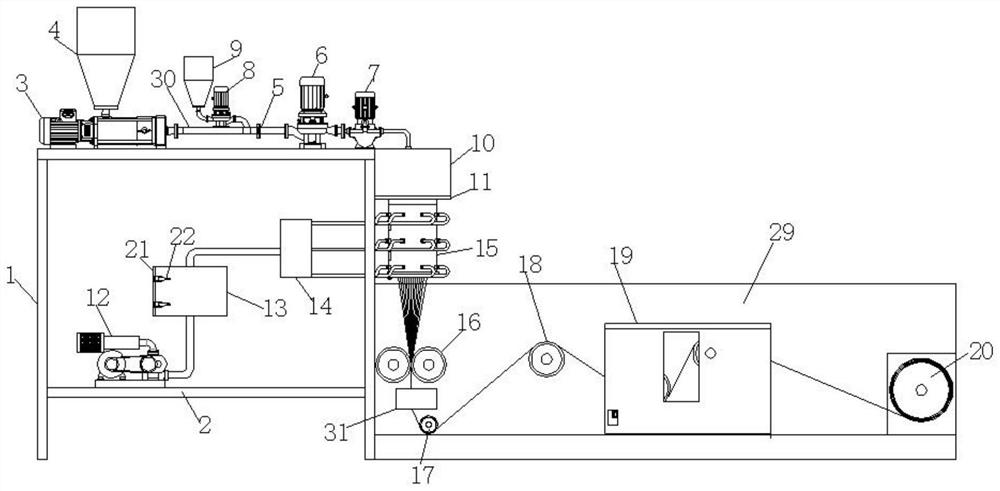

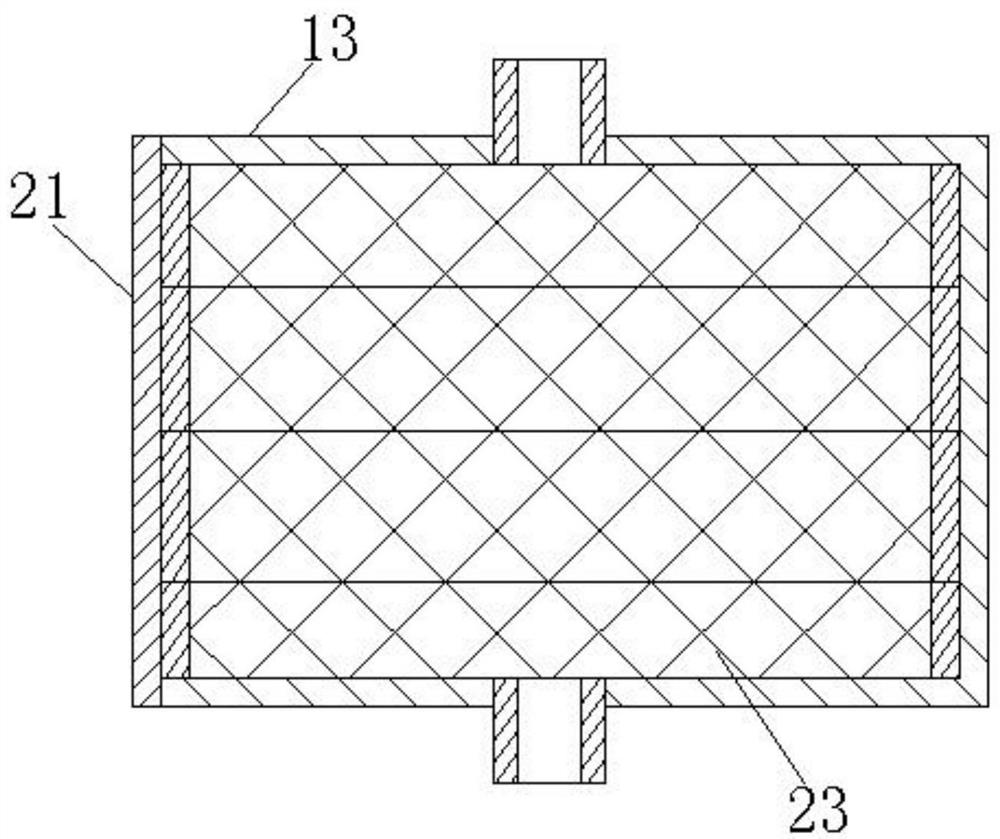

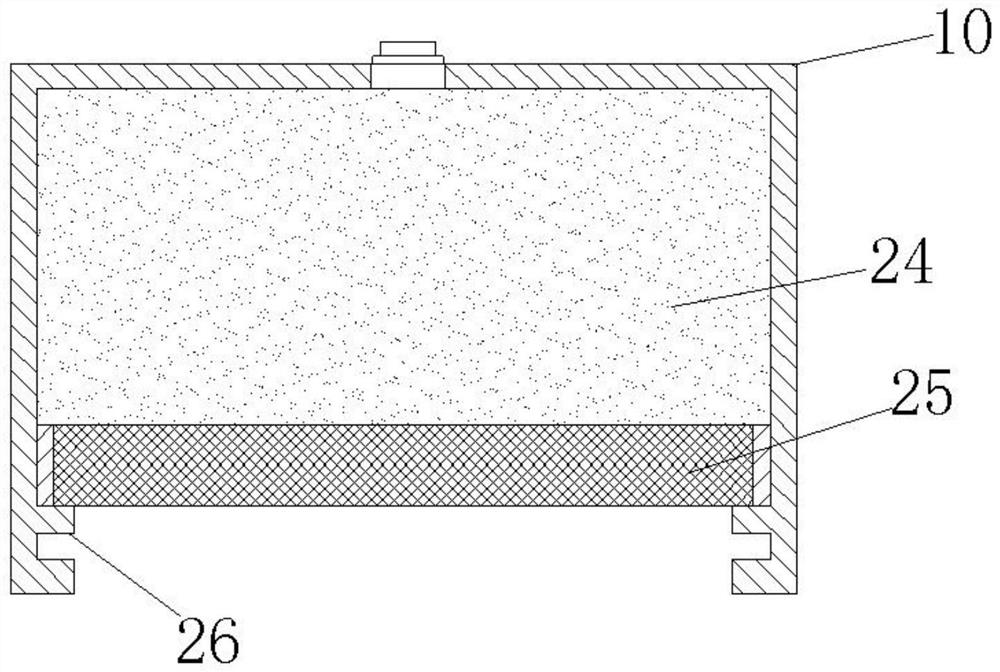

[0043] like Figure 1 to Figure 6 As shown, the embodiment of the present invention provides a production and processing equipment for high-gloss stretched textured yarn, including a frame 1 and a mounting plate 29 fixedly connected to the side wall of the frame 1; a beam 2 fixedly connected to the inside of the frame 1 ; From left to right, the main feeding assembly, static mixer 5, booster pump 6 and metering pump 7 fixedly connected to the upper wall of the frame 1 are fixedly connected between the main feeding assembly and the static mixer 5. Material pipe 30, the outer wall of the main feed pipe 30 is provided with auxiliary material adding components; the spinning box 10 that is fixedly connected to the side wall of the frame 1 and is located on the upper side of the mounting plate 29 and is clamped on the lower wall of the spinning box 10 through a sliding structure The spinneret 11, the inlet end of the spinning box 10 is fixedly connected to the outlet end of the mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com