Special tobacco curing method for heat pump intensive curing barn

A dense curing barn and heat pump technology, which is applied in the fields of application, tobacco, and tobacco preparation, can solve the problems of unmatched heat pump intensive curing barns, and achieve the effects of simplifying the curing process, reducing workload, and making it easier to implement and promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Embodiment 1: Firstly, operate the tobacco clip loading process on the operating table to ensure that the quality of the tobacco leaves in the same clip and in the curing room is consistent. During the tobacco loading process, ensure that the tobacco leaves are evacuated and evenly distributed on the tobacco clips, and the leaf bases are aligned. The effective cigarette width is 8cm, each cigarette weighs 12kg, and the cigarette capacity per room is 4300kg. After hanging in the barn, the following special flue-curing steps are carried out in sequence:

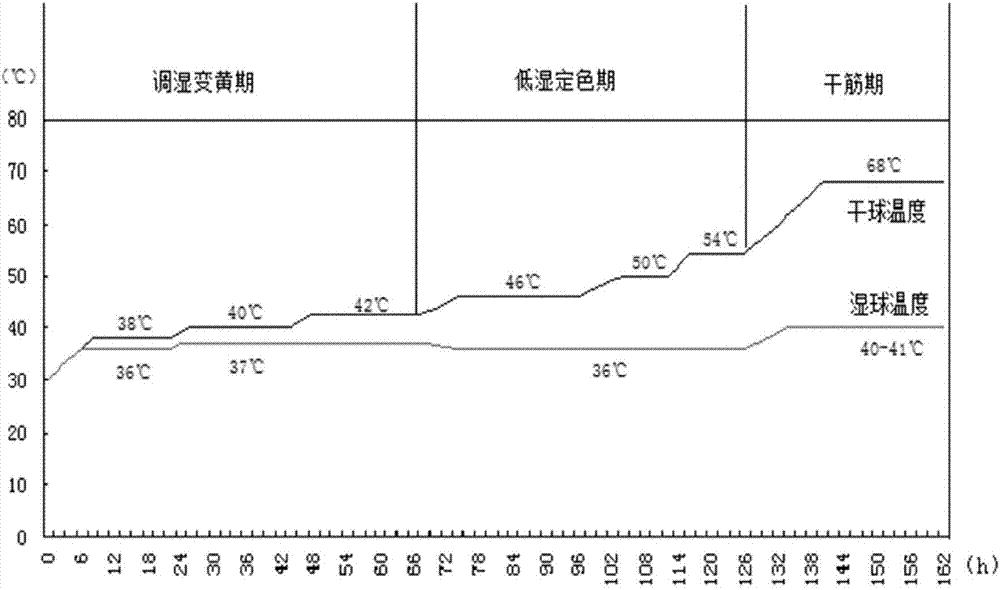

[0023] (1) Humidity adjustment and yellowing period: ① Put the tobacco into the barn, close the moisture removal window, and then ignite to raise the dry bulb temperature to 38°C at a heating rate of 1°C / h, and at the same time, the wet bulb temperature is stable at 36°C. ℃, stabilize the temperature for 20 hours, until the tobacco leaves turn yellow at 5-6 hours; in this step, after ignition, first set the speed of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com