Method for producing bicycle wheel fellone using magnesium alloy section bar

A manufacturing method and technology of magnesium alloys, which are applied in the control equipment, manufacturing tools, metal extrusion and other directions of metal extrusion, can solve the problems of poor plastic deformation performance, narrow process control range, unfavorable mechanical forming, etc., and improve the yield of finished products. , The overall performance is consistent and uniform, and the operation is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

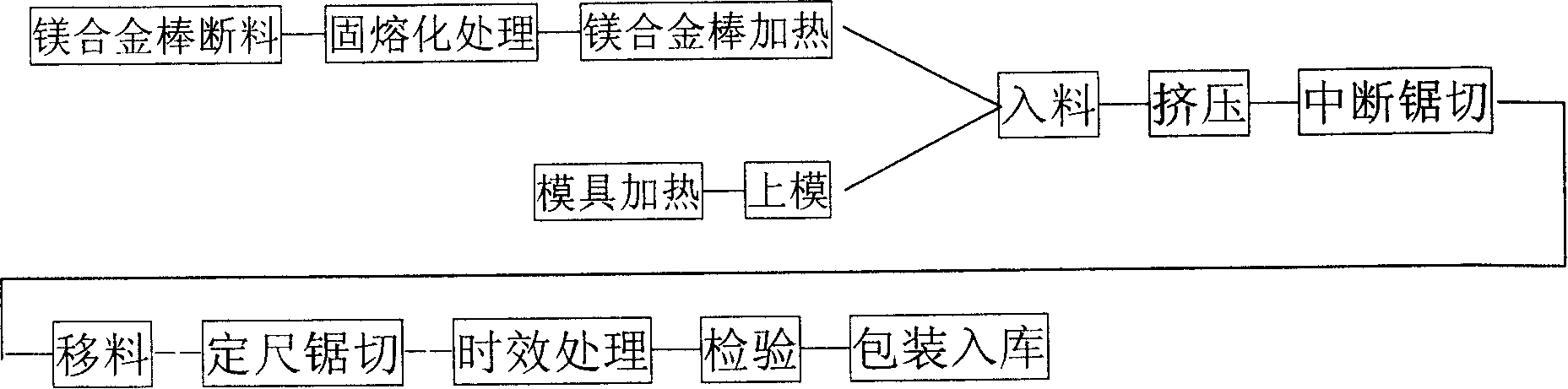

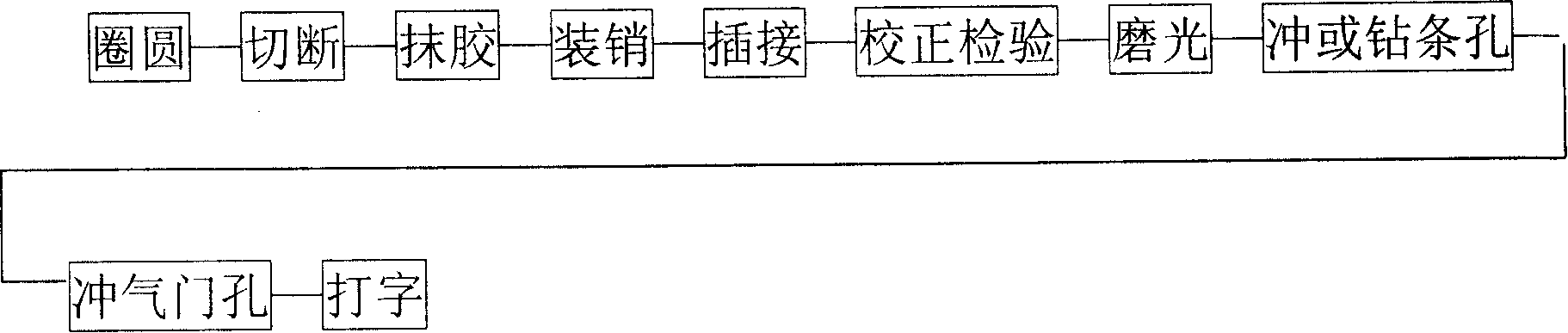

[0033] The production process of magnesium alloy rims includes two processes of extrusion and forming. The specific implementation methods of these two processes are as follows:

[0034] 1. If figure 1 As shown, the magnesium profile extrusion process includes the extrusion process including magnesium alloy rod cutting, solid melting treatment, magnesium alloy rod heating, mold heating, upper die, feeding, extrusion, interrupt sawing, material transfer-, fixed Ruler sawing, aging treatment, inspection, packaging and warehousing.

[0035] Put the cut magnesium alloy rod into the heating furnace and heat it to the solid melting treatment temperature (400°C), keep it warm for 24 hours, then cool it down to room temperature in air; then heat it to 370°C, keep it warm for 2 hours, and enter the extrusion process; Before extrusion, the mold should be preheated, and the preheating temperature is 355°C, which is the extrusion temperature; extrusion requires a certain extrusion speed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com