Hot-dip galvanizing method for obtaining colored plating on flat steel

A hot-dip galvanizing and coating technology, applied in metal material coating process, coating, hot-dip plating process, etc., can solve the problems of easy occurrence of variegation, narrow process window range, and difficult control of coating color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

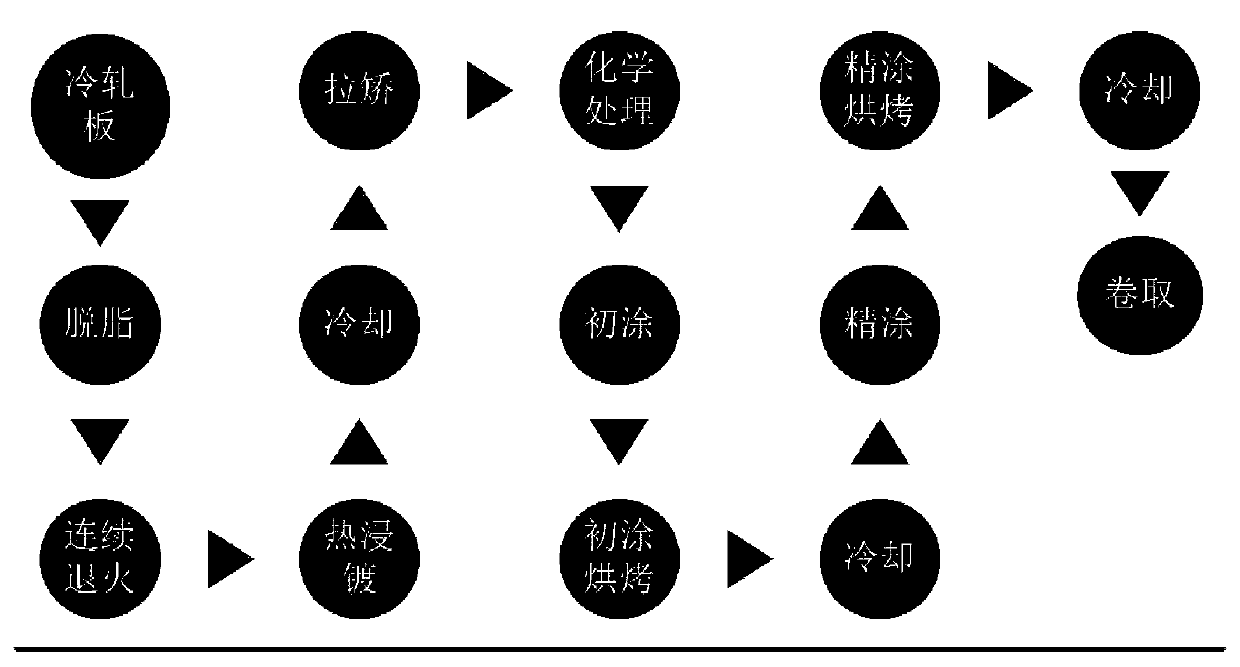

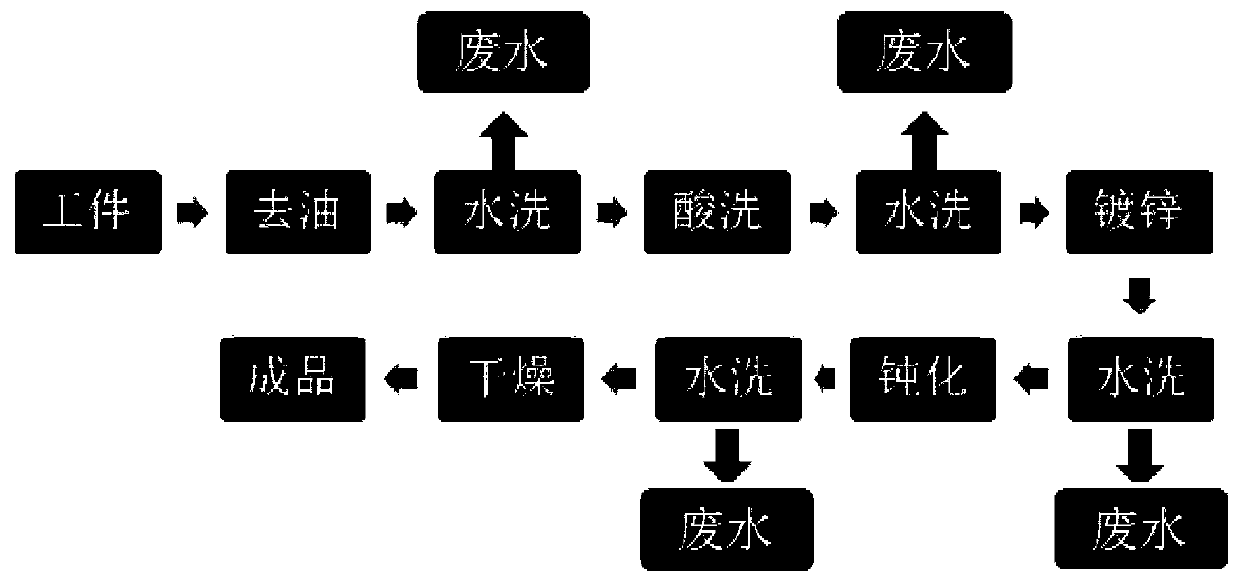

Method used

Image

Examples

Embodiment 1

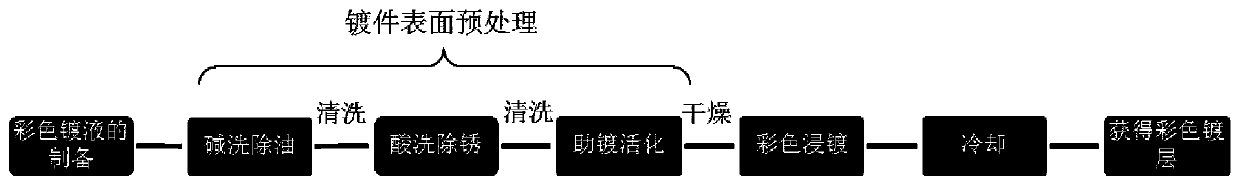

[0167] The color hot-dip galvanizing process is carried out on the cold-rolled steel plate with a thickness of 0.1mm. The size of the steel plate is 50mm×40mm×0.1mm. First, a special colored hot-dip galvanizing bath is prepared, and the surface of the plated parts is pretreated, and finally hot-dip galvanized Operation, the specific operation steps are as follows:

[0168] Step 1, prepare the plating solution

[0169] (1) After melting the zinc ingot, add the pre-prepared master alloy;

[0170] (2) Make the ratio of elements in the zinc solution satisfy Zn content of 98.75%, Mn content of 1%, Y content of 0.1%, Ce content of 0.08%, Cu content of 0.05%, and the balance is impurities.

[0171] Step 2, surface pretreatment of plated parts

[0172] (1) Soak the plated piece in 4wt.% NaOH solution at 70°C for 20 minutes to carry out alkali cleaning and degreasing, take it out after soaking, and clean it with clear water;

[0173] (2) Soak the plated piece in 15wt.% hydrochloric ...

Embodiment 2

[0205] The color hot-dip galvanizing process is carried out on a steel plate with a thickness of 5mm. The size of the steel plate is 50mm×40mm×5mm. First, a special color hot-dip galvanizing bath is prepared, and the surface of the plated part is pretreated, and finally the hot-dip galvanizing operation is performed. The specific operation Proceed as follows:

[0206] Step 1, prepare the plating solution

[0207] (1) After melting the zinc ingot, add the pre-prepared master alloy;

[0208] (2) Make the ratio of elements in the zinc solution meet the Zn content of 99.3%, the Mn content of 0.6%, the Y content of 0%, the Ce content of 0%, and the Cu content of 0.03%. The balance is impurities.

[0209] Step 2, surface pretreatment of plated parts

[0210] (1) Soak the plated parts in 5wt.% NaOH solution at 60°C for 25 minutes to carry out alkali cleaning and degreasing, take out after soaking, and clean with water;

[0211] (2) Soak the plated piece in 18wt.% hydrochloric aci...

Embodiment 3

[0234] The color hot-dip galvanizing process is carried out on a steel plate with a thickness of 10mm. The size of the steel plate is 70mm×50mm×10mm. First, a special color hot-dip galvanizing bath is prepared, and the surface of the plated part is pretreated, and finally the hot-dip galvanizing operation is performed. The specific operation Proceed as follows:

[0235] Step 1, prepare the plating solution

[0236] (1) After melting the zinc ingot, add the pre-prepared master alloy,

[0237] (2) Make the ratio of elements in the zinc solution meet the Zn content of 99.5%, the Mn content of 0.4%, the Y content of 0.05%, the Ce content of 0%, and the Cu content of 0.05%. The balance is impurities.

[0238] Step 2, surface pretreatment of plated parts

[0239] (1) Soak the plated parts in 6wt.% NaOH solution at 50°C for 35 minutes to carry out alkaline cleaning and degreasing, take out after soaking, and clean with water

[0240] (2) Soak the plated parts in 20wt.% hydrochlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com