Preparation method and application of Er2O3 coating

An er2o3 coating technology, which is applied in the field of Er2O3 coating preparation, can solve the problems of harsh service environment, cracks and peeling of the coating, and achieve precise and controllable process parameters, green and environmentally friendly preparation process, and convenient equipment operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

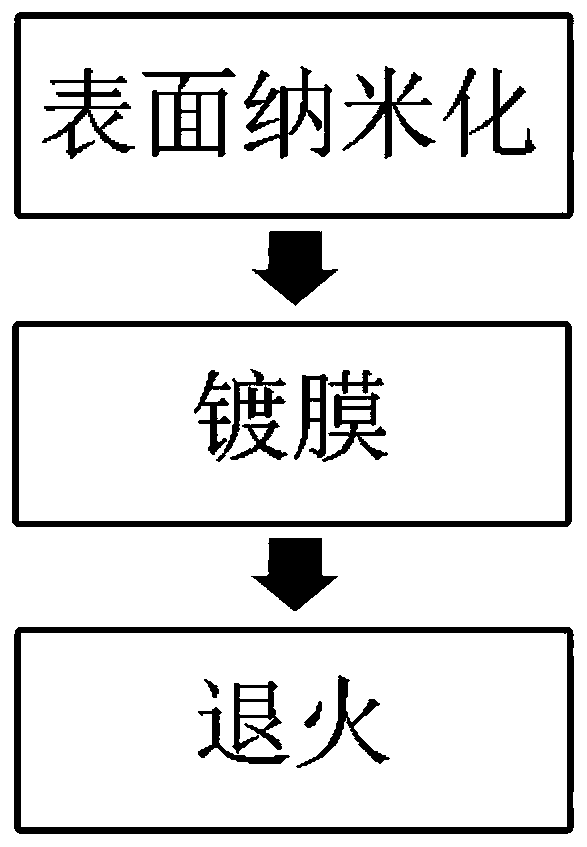

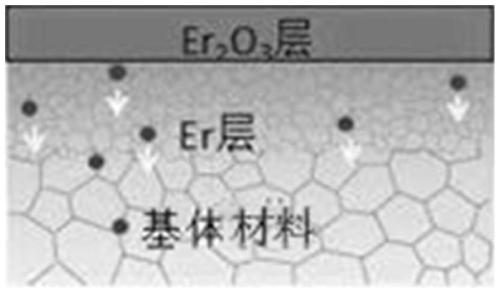

[0036] a kind of Er 2 o 3 The preparation method of coating, this method comprises the following steps:

[0037] (1) Surface nanometerization: the cleaned matrix material is fixed in front of the nozzle of the supersonic particle shot peening equipment and subjected to surface shot peening treatment to obtain a surface nano layer. The supersonic particle shot peening technology is selected for shot peening of the coating substrate. On the one hand, a nanocrystalline layer of a certain thickness can be prepared on the surface of the substrate by controlling the process parameters of the supersonic particle shot peening. After the substrate surface of the present invention is nano-treated, the diffusion speed of Fe and Er elements is accelerated, and the required diffusion activation energy is reduced, thereby greatly reducing the subsequent diffusion annealing temperature and shortening the annealing time. This feature not only eliminates the negative impact of high temperatu...

Embodiment 1

[0061] a kind of Er 2 o 3 The preparation method of the coating is as follows:

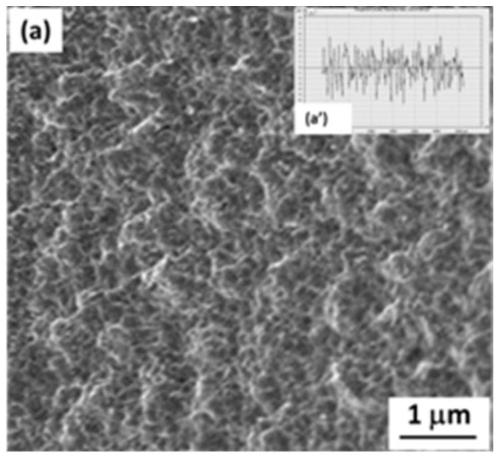

[0062] (1) Fix the cleaned 100Cr6 steel sheet before the nozzle of the supersonic particle shot blasting equipment, the distance to be sprayed is 30mm from the nozzle, the carrier gas pressure of the supersonic particle bombardment equipment is 2.5MPa, and the nozzle walking speed is 1mm / s ( Converted to the shot peening area per unit time is 1.5cm 2 / s), the shot peening incident angle is 90°, and the shot peening medium is spherical alumina powder (corundum powder), with a diameter of 60 μm;

[0063] (2) Place the shot-peened steel base material obtained in step (1) in a magnetron sputtering vacuum chamber, and the background vacuum pressure of the vacuum chamber is 8.0×10 -4 pa, RF magnetron sputtering coating was carried out under the condition of sputtering power of 100W, the Er target with a purity of 99.95wt% was used as the sputtering source, Ar was introduced during sputtering, the Ar ...

Embodiment 2

[0071] a kind of Er 2 o 3 The preparation method of the coating is as follows:

[0072] (1) Fix the cleaned 100Cr6 steel sheet before the nozzle of the supersonic particle shot blasting equipment, the distance to be sprayed is 30mm from the nozzle, the carrier gas pressure of the supersonic particle bombardment equipment is 2.5MPa, and the nozzle walking speed is 1mm / s ( Converted to the shot peening area per unit time is 1.5cm 2 / s), the shot peening incident angle is 90°, and the shot peening medium is spherical alumina powder (corundum powder), with a diameter of 60 μm;

[0073] (2) Place the shot-peened steel base material obtained in step (1) in a magnetron sputtering vacuum chamber, and the background vacuum pressure of the vacuum chamber is 8.0×10 -4 pa, under the condition of sputtering power of 100W, carry out radio frequency magnetron sputtering coating, use Er target with a purity of not less than 99.95wt% as the sputtering source, pass Ar into it during sputteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com